Heater 0 and Heater 1 reading 2000°C

-

Danal said in Heater 0 and Heater 1 reading 2000°C:

Debugging step: Measure the resistance of each sensor Using a DVM or similar

Indeed! If they measure about 100kΩ at 20°C they should be ok and then carefully without shorting any pins measure from ground on say the Vin terminal to both pins of the thermistor input and report back readings.

-

FIRMWARE_NAME: RepRapFirmware for Duet 2 WiFi/Ethernet FIRMWARE_VERSION: 2.03 ELECTRONICS: Duet WiFi 1.0 or 1.01 FIRMWARE_DATE: 2019-06-13b2; Configuration file for Duet WiFi (firmware version 2.03) ; executed by the firmware on start-up ; ; generated by RepRapFirmware Configuration Tool v2.0.4 on Sat Oct 12 2019 17:04:55 GMT+0200 (Mitteleuropäische Sommerzeit) ; General preferences G90 ; send absolute coordinates... M83 ; ...but relative extruder moves M550 P"Predator" ; set printer name M665 R220 L440.4 B185 H420.607 ; Set delta radius, diagonal rod length, printable radius and homed height M666 X0 Y0 Z0 ; put your endstop adjustments here, or let auto calibration find them ; Network M552 S1 ; enable network M586 P0 S1 ; enable HTTP M586 P1 S0 ; disable FTP M586 P2 S0 ; disable Telnet M575 P1 B57600 S1 ;Serial Port for Panel Due ; Drives M569 P0 S0 ; physical drive 0 goes forwards M569 P1 S0 ; physical drive 1 goes forwards M569 P2 S0 ; physical drive 2 goes forwards M569 P3 S1 ; physical drive 3 goes forwards M584 X0 Y1 Z2 E3 ; set drive mapping M350 X16 Y16 Z16 I1 M350 E16 I1 ; configure microstepping with interpolation M92 X160.00 Y160.00 Z160.00 E412; E399 ; set steps per mm M566 X600.00 Y600.00 Z600.00 E160.00 ; set maximum instantaneous speed changes (mm/min) M203 X18000.00 Y18000.00 Z18000.00 E10000.00 ; set maximum speeds (mm/min) M201 X2000.00 Y2000.00 Z2000.00 E1000.00 ; set accelerations (mm/s^2) M906 X1000 Y1000 Z1000 E800 I50 ; set motor currents (mA) and motor idle factor in per cent M84 S30 ; Set idle timeout ; Axis Limits M208 Z0 S1 ; set minimum Z ; Endstops M574 X2 Y2 Z2 S1 ; set active low and disabled endstops ; Z-Probe M558 P5 R0.4 H20 F1200 T6000 A10 S0.02 ; set Z probe type to effector and the dive height + speeds G31 P100 X0 Y0 Z-0.13 ; set Z probe trigger value, offset and trigger height M557 R180 S18 ; define mesh grid ; Heaters M305 P0 T100000 B4138 C0 R4700 ; set thermistor + ADC parameters for heater 0 M143 H0 S120 ; set temperature limit for heater 0 to 120C M305 P1 B4725 C7.060000e-8 R4700 ; set thermistor + ADC parameters for heater 1 M143 H1 S280 ;M305 P2 B4725 C7.060000e-8 R4700 ; set thermistor + ADC parameters for heater 1 ;M143 H2 S280 ; set temperature limit for heater 1 to 280C ; Fans M106 P0 S0 F100 C"Bauteillüfter" ; set fan 0 value, PWM signal inversion and frequency. Thermostatic control is turned off M106 P1 S0.66 H1 F100 T60 L0.3 X0.75 ; set fan 1 value, PWM signal inversion and frequency. Thermostatic control is turned on ; Tools M563 P0 D0 H1 F0 ; define tool 0 G10 P0 X0 Y0 Z0 ; set tool 0 axis offsets G10 P0 R0 S0 ; set initial tool 0 active and standby temperatures to 0C ; Custom settings are not defined M98 P0:/sys/retract.g T0 M501 M572 D0 S0 G29 S1I'm measuring 120k for the hotend Thermistor and 114k for the Bed thermistor, which should be fine....

I mesaure a Voltage of 3.2V from Thermistor0-pin, Thermistor1-pin and Thermistor2-pin to GND. ---However, the VSSA voltage is slowly crawling from 3.2V to 0V while i measure between VSSA and GND. shouldnt VSSA be GND potential?

edit: i just noticed... there is a resettable fuse F1... how do i reset it?

-

@Bakak said in Heater 0 and Heater 1 reading 2000°C:

I mesaure a Voltage of 3.2V from Thermistor0-pin, Thermistor1-pin and Thermistor2-pin to GND. ---However, the VSSA voltage is slowly crawling from 3.2V to 0V while i measure between VSSA and GND. shouldnt VSSA be GND potential?

Yes, VSSA should be only a few millivolts above ground unless there is a short circuit between VSSA and a higher voltage. The polyfuse connects VSSA to GND. It is self-resetting.

-

@Bakak said in Heater 0 and Heater 1 reading 2000°C:

there is a resettable fuse F1... how do i reset it?

it should as dc42 said self reset; to test it power off the board and measure resistance F1 it, should probably be in the 0-1 ohm range if working.

-

Overload... i guess it broke -.-

-

What type of fuse is this?

I'm confident, that i can replace it -

@Bakak said in Heater 0 and Heater 1 reading 2000°C:

Overload... i guess it broke -.-

may sound silly but double check you have a 0 reading when shorting the leads, and make sure to apply some pressure to pierce any oxide layer on the solder joint.

@Bakak said in Heater 0 and Heater 1 reading 2000°C:

What type of fuse is this?

I'm confident, that i can replace itshematic says:

Fuse to protect the SAM from VIN applied to VSSA in error.

Multicomp MC36207, Bel Fuse 0ZCJ0020FF2E -

yep. just measured again in high ohm range, 15M.

thanks for your help, this saves me a ton of money

-

@droftarts I'm using the latest release of ReprapFirmware 3, upgrading was the first thing I did. All other things works just perfekt.

@Danal with unplugged sensor it also shows 2000

@dc42 what could I do to test, what is the problem?

Thanks to all so far

-

Bourns MF-MSMF014 is another suitable part number for the VSSA fuse. You can solder the new fuse on top of the old one, which will be easier than trying to remove the old one.

I've never heard of the VSSA polyfuse failing before.

As a temporary workaround, you could connect VSSA on one of the thermistor connectors to GND on one of the endstop connectors. But then you lose the protection against a thermistor short to VIN, which is what the fuse is there to protect against.

-

haha! finally i'm the first to achieve something

I just ordered some of the fuses. don't want to run the board unprotected

-

You don't need a poly fuse or even a surface mount one, any odd fast acting 100mA or so fuse could be either wired between VSSA and GND or solderd in parallell with the existing one would provide protection.

-

-

(

this one.

-

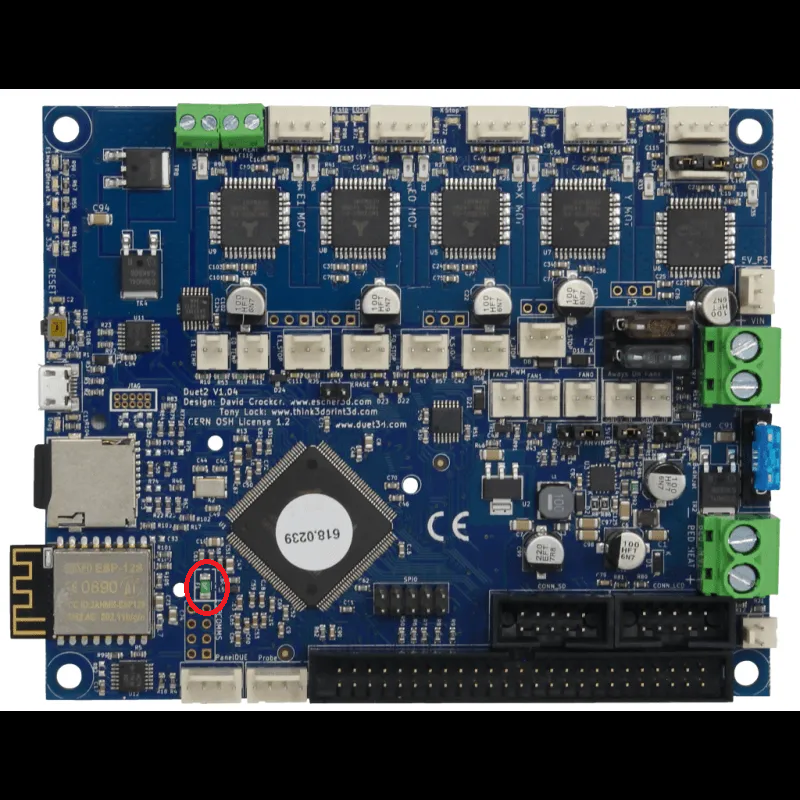

@CaiJonas said in Heater 0 and Heater 1 reading 2000°C:

@Bakak @dc42 I don't get it, what fuse can I measure and what should the value be?

What revision is your Duet WiFi?

- If it's 1.0 or 1.01 then see https://duet3d.dozuki.com/Wiki/Connector_and_spare_part_numbers#Section_VSSA_fuse.

- If it's 1.02 or later then the polyfuse is the green component between the processor and the WiFi module.

Please check that you are still getting 2000C readings even with just USB power applied (no VIN power).

-

@dc42 I measured a value of 1.1-1.2 ohm and I still get 2000°C readings with just USB power applied.

-

If you disconnect the thermistors completely and use your multimeter to measure the voltage between the two pins of one of the thermistor connectors, with USB power applied, what voltage does it read? Does it still read 2000C or does it change to -273C ?

-

@dc42 I measure excactly 3.3V on all three channels and temp stay on 2000C. Do you have a presumtion what the Problem could be?

-

It sounds like either a failure of the main processor (but this type of failure would be very unusual) or a configuration problem. Please post your config.g file.

-

@dc42 ```

; Configuration file for Duet WiFi (firmware version 1.20 or newer)

; executed by the firmware on start-up

;

; generated by RepRapFirmware Configuration Tool on Sun Jul 15 2018 19:42:49 GMT+0200 (Mitteleuropäische Sommerzeit); General preferences

G90 ; Send absolute coordinates...

M83 ; ...but relative extruder moves

M555 P1 ; Set firmware compatibility to look like native output

M665 X-0.406 Y-0.805 Z0.000 R113.116 L236 B110 H233.000 ; Set delta radius, diagonal rod length, printableradius and homed heigth

M666 X0.280 Y-0.620 Z0.340 ; Endstop calibration; Network

M550 Cai's Delta ; Set machine name

M552 S1 ; Enable network

M587 S"FRITZ!WLAN Repeater 1750E" P"12041990" I192.168.2.112 ; Configure access point. You can delete this line once connected

M586 P0 S1 ; Enable HTTP

M586 P1 S0 ; Disable FTP

M586 P2 S0 ; Disable Telnet; Drives

M569 P0 S0 ; Drive 0 goes forwards

M569 P1 S0 ; Drive 1 goes forwards

M569 P2 S0 ; Drive 2 goes forwards

M569 P3 S1 ; Drive 3 goes forwards Extruder

M350 X16 Y16 Z16 I1 ; Configure microstepping with interpolation for axis

M350 E16 I1 ; Configure microstepping with interpolation for extruder

M92 X200 Y200 Z200 ; Set steps per mm for axis 160

M92 E830 ; Set steps per mm for extruder 830

M203 X18000 Y18000 Z18000 E3500 ; Set maximum speeds (mm/min)

M566 X900 Y900 Z900 E3500 P1 ; Set maximum instantaneous speed changes (mm/min)

M201 X1800 Y1800 Z1800 E3500 ; Set print acceleations (mm/s^2) E3600

M906 X1400 Y1400 Z1400 E1200 I10 ; Set motor currents (mA) and motor idle factor in per cent

M84 S25 ; Set idle timeout; Axis Limits

M208 Z0 S1 ; Set minimum Z; Endstops

M574 X2 S1 P"xstop" ; X min active high endstop switch

M574 Y2 S1 P"ystop" ; Y min active high endstop switch

M574 Z2 S1 P"zstop" ; Z min active high endstop switch; Z-Probe

M558 P5 C"zprobe.in" H2 I1 F600 R0.2 T18000 A5 S0.05 ; Set Z probe type to modulated and the dive height + speeds

G31 P1000 X0 Y0 Z-0.050 ; Set Z probe trigger value, offset and trigger height G31 P0 X0 Y0 Z0

M557 R90 S30 ; Define mesh grid; Fans

M950 F0 C"fan0" ;

M950 F1 C"fan1" ;

M950 F2 C"fan2" ;

M106 P0 S0 H-1 ; Set fan 0 value, PWM signal inversion and frequency. Thermostatic control is turned off

M106 P1 S1 H1 T45 C"Heastsink" ; Set fan 1 value, PWM signal inversion and frequency. Thermostatic control is turned on

M106 P2 S1 H0 T45 C"PCB" ; Set fan 2 value, PWM signal inversion and frequency. Thermostatic control is turned on; Heaters

M308 S0 P"bed_temp" Y"thermistor" T100000 B4725 C7.06e-8 ; define bed temperature sensor B4138

M950 H0 C"bed_heat" T0 ; heater 0 uses the bed_heat pin, sensor 0

M143 H0 S120 ; Set temperature limit for heated bed to 120°C

M307 H0 A230.8 C823.2 D4.2 B0 ; Set PID BedM308 S1 P"e0_temp" Y"thermistor" T100000 B4725 C7.06e-8 ; define E0 temperature sensor

M950 H1 C"e0_heat" T1 ; heater 1 uses the e0_heat pin and sensor 1

M143 H1 S280 ; Set temperature limit for heater 1 to 280°C

M307 H1 A545 C200 D5 B0 ; Set PID NozzleM302 S100 R100 ; Set minimal extrude/retract temperature

; Tools

M563 P0 F0 D0 H1 L0 ; Define tool 0

G10 P0 X0 Y0 Z0 R0 S0 ; Set tool 0 axis offsets, Set initial tool 0 active and standby temperatures to 0C