Rat rig v-core pro COREXYU

-

for bed correction ç OK g32c ok

I miss details and chario u I just have to configure it becomes complicatedpour la correction du lit ç OK g32c ok

Les détails me manquent et chario je dois juste configurer ça devient compliqué -

@neetspeed If E1 is going the wrong way, change direction with M569 P4 'S' parameter.

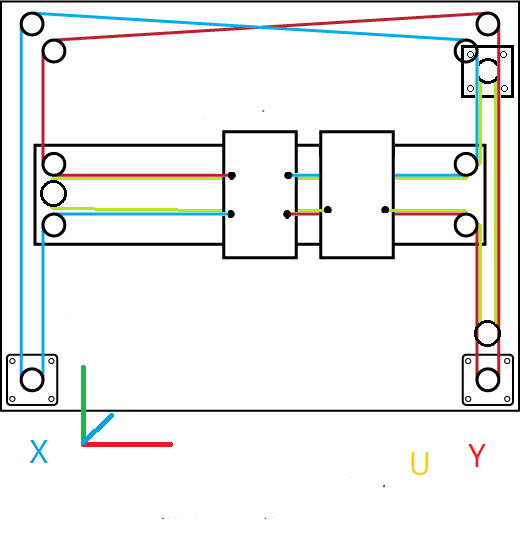

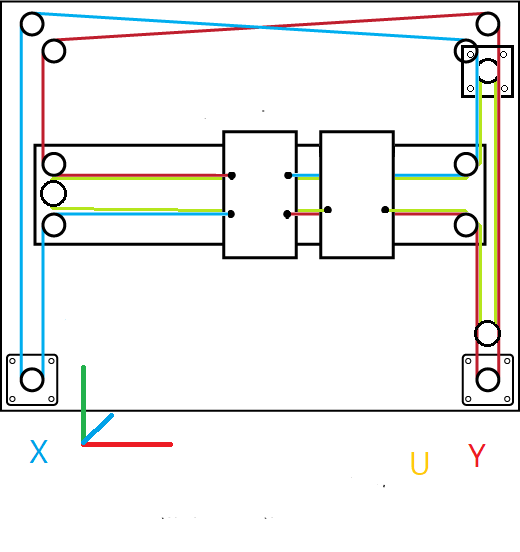

For the Markforged kinematics, can you post a diagram of your belt layout? You say that it is CoreXY + Markforge U, is that correct? Or do you have two motors for U and V, like a second CoreXY?

If you are running CoreXYUV, use M669 K8. See https://duet3d.dozuki.com/Wiki/Gcode#Section_M669_Set_kinematics_type_and_kinematics_parameters

If you are running CoreXY + Markforge U, you have to work out the transformation matrix. This is how one axis moving affects the others. It's also M669, but with additional parameters for X, Y and U. To do this, you need to work out how each axis moves when the others move. X and Y should be the same as a normal CoreXY, but with an additional value for U. Send M669 to see the current matrix; in CoreXY mode, I get (I have added the comments):

Kinematics is CoreXY, matrix: 1.00 1.00 0 ; This how X, Y and Z motors move when there is a positive X move 1.00 -1.00 0 ; This how X, Y and Z motors move when there is a positive Y move 0 0 1.00 ; This how X, Y and Z motors move when there is a positive Z moveU needs to move when X and Y move. It will probably be something like:

1.00 1.00 0 0 ; This how X, Y, U and Z motors move when there is a positive X move 1.00 -1.00 -1.00 0 ; This how X, Y, U and Z motors move when there is a positive Y move 0 0 1.00 0 ; This how X, Y, U and Z motors move when there is a positive U move 0 0 0 1.00 ; This how X, Y, U and Z motors move when there is a positive Z moveA positive X move shouldn't move the U axis (even though the X and Y motors move). A positive Y move will make the U axis move positively (but may move negatively, so check), so needs -1 to counteract this. A positive U move shouldn't move X or Y. However, this is just a guess! You have the machine in front of you, so should be able to work this out.

This would give an M669 command like:

M669 X1:1:0:0 Y1:-1:-1:0 U0:0:1:0 Z0:0:0:1

Which would replace the one in your config.g.Seeing a picture of your belt setup would help, but I think this is close.

Ian

-

hi guys

thank you ,

I have exactly this kinematics of belt

my corexy

m669

kinematics is CoreXY, matrix:

1.00 1.00 0

1.00 -1.00 0

0 0 1.00my first chario, stop 9.5 mm before the charion U, which has the same dimensions as x in mirror, finally I suppose

and I'm not M669, I have M667 S1

salut les gars

Merci ,

J'ai exactement cette cinématique de ceinturemon corexy

m669

la cinématique est CoreXY, matrice:

1,00 1,00 0

1,00 -1,00 0

0 0 1,00mon premier chario, arrêtez-vous à 9,5 mm avant le charion U, qui a les mêmes dimensions que x dans le miroir, enfin je suppose

et je ne suis pas M669, j'ai M667 S1

-

This post is deleted! -

@droftarts said in Rat rig v-core pro COREXYU:

This would give an M669 command like:

M669 X1:1:0:0 Y1:-1:-1:0 U0:0:1:0 Z0:0:0:1

Which would replace the one in your config.g.That looks correct to me except that the U motor values should come after the Z motor values, not before. If you also put parameter K1 in that command it will be this:

M669 K1 X1:1:0:0 Y1:-1:0:-1 U0:0:0:1 Z0:0:1:0then it can replace your M667 command.

-

@neetspeed, in case you didn't notice, I just corrected my previous reply.

-

@dc42 said in Rat rig v-core pro COREXYU:

M669 K1 X1:1:0:0 Y1

0:-1 U0:0:0:1 Z0:0:1:0

0:-1 U0:0:0:1 Z0:0:1:0I saw the correct version

thank you dc42 really

Y, lost half his speed,

but the movement XY works it is necessary I create the axis U

-

Yes you need to create the U axis using the M584 command. https://duet3d.dozuki.com/Wiki/Gcode#Section_M584_Set_drive_mapping

-

speed will recover?

-

@neetspeed said in Rat rig v-core pro COREXYU:

speed will recover?

I don't know why the speed has changed. When you have added the U axis in M584, please post your config.g file.

-

error G28 I dig

config (3).gG28 U

Error: Bad command: '' 'Accueil U en haut de l'axe' ''

Error: G0/G1: insufficient axes homed -

@neetspeed Have you added homing of U to homeall.g, and/or created homeu.g? Or, for now, set the U axis position with G92 U[postition], eg

G92 U100.Ian

-

@neetspeed

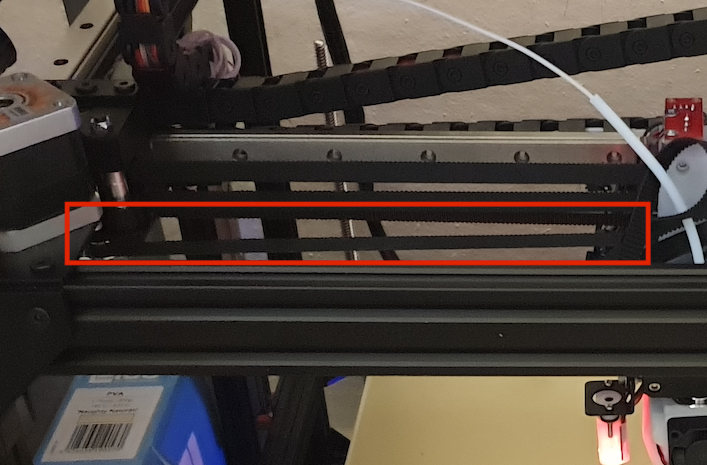

These two belts do not look parallel. I think they are for the CoreXY carriage. This will cause the belt to get tighter as the carriage moves left, and will create LOTS of problems. Belt paths MUST be straight, and at 90º. The only place where they don't have to be straight is at the back, where the X and Y belt cross, like your picture earlier:

Ian

-

no c the U belt

no c the U belt

temporary for the moment but x goes first and does not bother thanks -

-

@neetspeed From your config.g this is wrong:

M584 X0 Y1 Z2:4 E3 U3 E4:; deux moteurs Z connectés aux sorties pilote Z et E1You have E3 and U3 using the same driver, Z4 and E4 using same driver, and E4: expects another driver! Where are U axis and the two Extruder axes connected?

c well E8,

for driver 4 of the duex?What do you mean? You want to connect second E to driver 4 of Duex? See here for Duex wiring diagram: https://duet3d.dozuki.com/Wiki/Duex_wiring_diagrams

Remember to define motors with M569. Perhaps try:

M569 P5 S1 ; physical drive 5 goes backwards, E2 on Duex M569 P6 S1 ; physical drive 6 goes backwards, E3 on Duex M569 P7 S1 ; physical drive 7 goes backwards, E4 on Duex M569 P8 S1 ; physical drive 8 goes backwards, E5 on Duex M569 P9 S1 ; physical drive 9 goes backwards, E6 on Duex M584 X0 Y1 Z2:4 U3 E5:6 ; Extruders on Duex E2 and E3Ian

-

Hi

thank you

the formula seems good for the corexy mark forged,well I was too fast this afternoon, and I was wrong on the engine addressing or the speed problem and the rest,

everything is ok on the movements, and the g28 but an error that I seek and I pursue

correct settings for the homeconfig.g

homeall.g

homeu.g

homex.gG28 U

Error: Bad command: '' 'Reception U at the top of the axis' ''salut

Merci

la formule semble bonne pour la marque corexy forgée,eh bien j'étais trop rapide cet après-midi, et j'avais tort sur l'adressage du moteur ou le problème de vitesse et le reste,

tout va bien sur les mouvements, et le g28 mais une erreur que je cherche et je poursuis

réglages corrects pour la maisonhomex.g -

I have set X Y Z

but homeu.g I don't understand yet

its working well but error display

homeu.gJ'ai mis X Y Z

mais homeu.g je ne comprends pas encore -

@neetspeed, you have this line at the start of your home.g file:

'' 'Accueil U en haut de l'axe' ''

Put a ; character at the start of that line.

-

I did it exactly,

thank youto configure layer ventilation.

I have 12 volt fans and to keep the flow under control,

I connect them to fan 3 and fan 4 duex5 for chario 1 (F3) and chario 2 (F4)

with the fuse on 12v for the duex5, this is correct?my tool line knowing that

my the extruder motor are on E3 and E8 the motor; Fans

M106 P3 C"fan couche 1" S0 I0 F500 H-1 ; set fan 3 name, value, PWM signal inversion and frequency. Thermostatic control is turned off

M106 P1 C"fan hotend 1" S1 I0 F500 H1 T45 ; set fan 1 name, value, PWM signal inversion and frequency. Thermostatic control is turned on

M106 P4 C"fan couche 2" S0 I0 F500 H-1 ; set fan 4 name, value, PWM signal inversion and frequency. Thermostatic control is turned off

M106 P2 C"fan hoten 2" S1 I0 F500 H2 T45 ; set fan 2 name, value, PWM signal inversion and frequency. Thermostatic control is turned on; Tools outils

M563 P1 S"hotend gauche" D0 H1 F3 F1 ; define tool 1

G10 P1 X0 Y0 Z0 ; set tool 1 axis offsets

G10 P1 R0 S0 ; set initial tool 1 active and standby temperatures to 0C

M563 P2 S"hotend droit" D1 H2 X3 F4 F2 ; define tool 2

G10 P2 X0 Y0 Z0 ; set tool 2 axis offsets

G10 P2 R0 S0 ; set initial tool 2 active and standby temperatures to 0CJe l'ai fait exactement,

Mercipour configurer la ventilation des couches.

J'ai des ventilateurs de 12 volts et pour garder le débit sous contrôle,

Je les connecte au ventilateur 3 et au ventilateur 4 duex5 pour chario 1 (F3) et chario 2 (F4)

avec le fusible sur 12v pour le duex5, c'est correct?ma ligne d'outils sachant que

mon moteur d'extrudeuse est sur E3 et E8 le moteur