What kind of servo motor are recommend connect to duet 2 wifi?

-

@bearer i want to make 7 extruder tool changer.

-

OK, then you don't need servos at all.

The carriage has a tool lock driven by a stepper motor that lock/unlocks a tool. Macros are auto-invoked by the Duet firmware when it sees a T0 or T1 or whatever, and those macros position the carriage, lock a tool, or park and unlock a tool, or whatever.

All done with the XY steppers and the tool lock stepper.

Watch the video, and you will see a Jubilee pick up a tool and print with it.

At about 45 seconds, it parks the first tool and mounts a different one. The in/out motion on pickup is wiping the nozzle on a fixed strip of silicone just below the parking stall.

-

More info on the Jubilee:

https://github.com/machineagency/jubilee

It is one of the better toolchangers out there, right now.

-

@Danal said in What kind of servo motor are recommend connect to duet 2 wifi?:

E3D/Jubilee style

rotary style.

-

@Danal i see... i prefer rotary motion because it just move directly like the clock. Example clock at 1 pm is E1, 2pm is E2 and same to others extruder position. So it will take less than time to change to another extruder.

-

Okay, you will still not be able to control a continuous rotation servo to a specific location. You might be able to find a 360 degree servo but it will not be a continuous rotation servo. However a stepper motor may be easier and smoother as you can control acceleration and jerk.

-

@bearer so which brand or model of 360 servo motor are recommend to used in duet 2 wifi board?

-

@daxzero said in What kind of servo motor are recommend connect to duet 2 wifi?:

@bearer so which brand or model of 360 servo motor are recommend to used in duet 2 wifi board?

The reason why nobody is answering that is: Almost any of them. All servos that take 1000 to 2000 ms pulses will work. Which is 99% of them.

So choosing the servo has almost nothing to do with the Duet. You need to choose it based on torque, speed, positioning accuracy, rotating vs. positional, whatever you need. The Duet will drive it.

Oh, and I strongly agree with @bearer, a stepper motor is a MUCH better choice to drive a rotary tool changer table, as vs. a servo. As he said, accel, speed, decell will be important to moving that much mass, and a Duet driven stepper does that as a base function. Servos don't.

-

@Danal Ok. Can i used gcode to control stepper motor for rotary tool changer table?

-

@daxzero said in What kind of servo motor are recommend connect to duet 2 wifi?:

Can i used gcode to control stepper motor for rotary tool changer table?

just set up the steps/mm as steps/degree and use it like any other stepper

-

you mean yes and able to do that on slicer, right?

-

@Danal i just want to know more about servo motor and what happen if i do it.

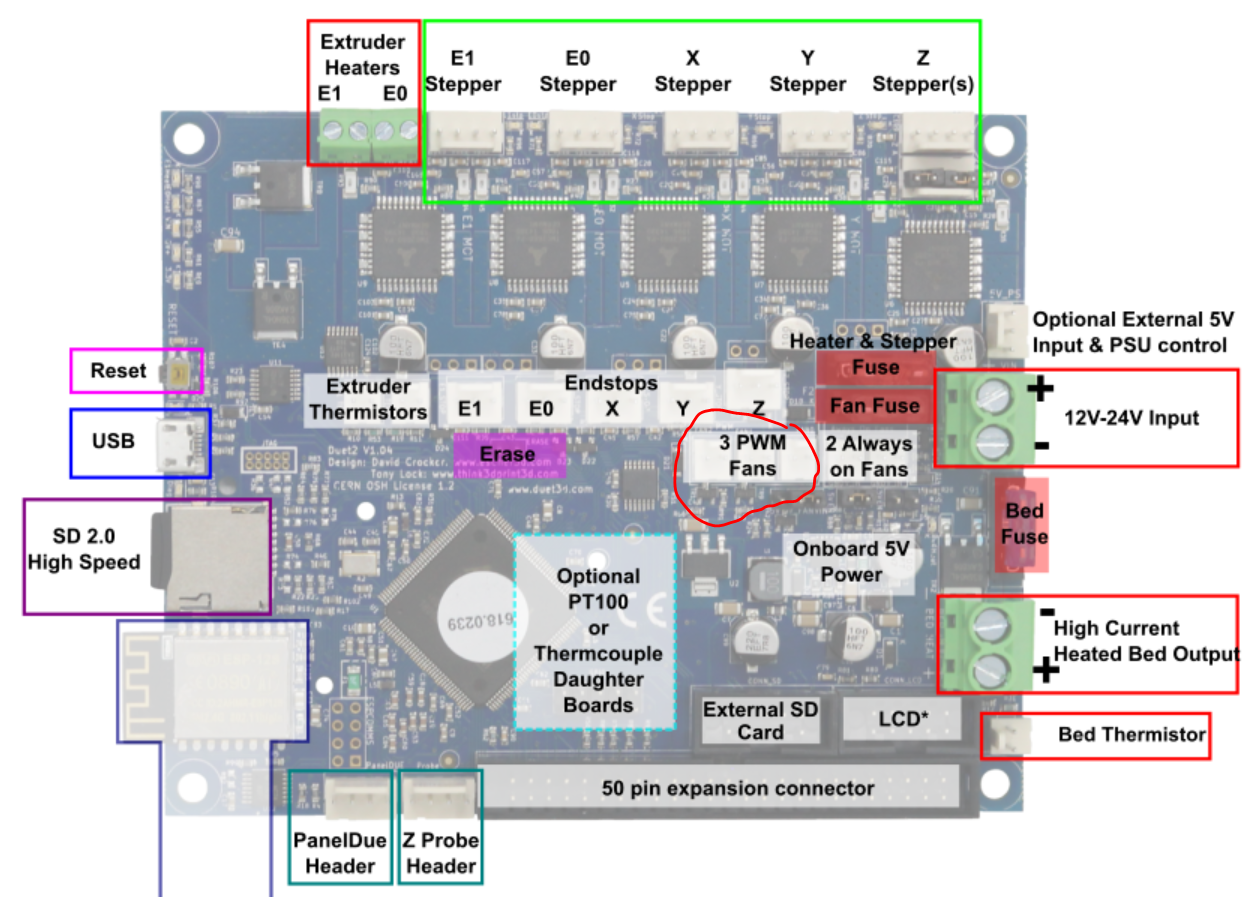

the red circle highlighted is also used to servo motor right?

if yes, then can i used gcode to control it?

-

-

@daxzero

i just want to know more about servo motor and what happen if i do it.

Looks like you are mixing things up. You want to perform a task, right? As far as I’ve understood, you want to build a tool changer, i.e. a mechanism which puts the requested tool at a certain position - either by rotary or linear motion - so that it can be picked up.

So that’s the goal. But, instead of asking how to achieve this, you focus on servos. Sure, you can use a servo to control the required motion, but your posts tell me that you are missing the point: instead of getting the task done, you follow a certain idea of how servos might work.

Well, with a Duet, (almost) anything goes. Even with servos. But first, have a look at your wallet: how much do you want to spend? RC-Servos can be cheap, all others are pretty costly. The cheaper ones are not very precise, the better ones are difficult to control. Lots of additional hardware, lots of Gcodes, lots of money. What for?

The simple answer is: use a stepper instead. It’s as well cheap as it is precise, it just does the job. When you are done with the tool changer, feel free to buy a cheap RC-servo and play with it. That’s exactly how I learnt about servos and how I can use them to improve my printer.

-

@daxzero said in What kind of servo motor are recommend connect to duet 2 wifi?:

you mean yes and able to do that on slicer, right?

I suggest you control the stepper motor for the tool or filament change in the tool change files, not the slicer

-

@infiniteloop said in What kind of servo motor are recommend connect to duet 2 wifi?:

The simple answer is: use a stepper instead. It’s as well cheap as it is precise, it just does the job. When you are done with the tool changer, feel free to buy a cheap RC-servo and play with it. That’s exactly how I learnt about servos and how I can use them to improve my printer.

@dc42 said in What kind of servo motor are recommend connect to duet 2 wifi?:

I suggest you control the stepper motor for the tool or filament change in the tool change files, not the slicer

Two very good answers. Both of these cannot be overstressed.

-

If you use a stepper motor to do the lock and unlocking, does it mean it will take up a stepper driver port? I have a duet2 +duex5. Can I use a pwn fan output to drive it?

-

A stepper needs a stepper driver port. It will not run on PWM.

-

A D2 + Duex5 can be configured to support:

X, Y, ZZZ (three motor leveling for bed), U (tool lock) and 4 extruders on tools. At that point, it is out of drivers.

See https://github.com/machineagency/jubilee for details, including running D2/Duex5 config.g and toolchange (tpre, tpost, tfree) files.

-

@daxzero

You can try this Geneva Indexing Table Mechanism.

Just use a stepper motor.https://www.youtube.com/watch?v=8tchOhvDgQM

https://www.youtube.com/watch?v=lPA9_cqAC-w