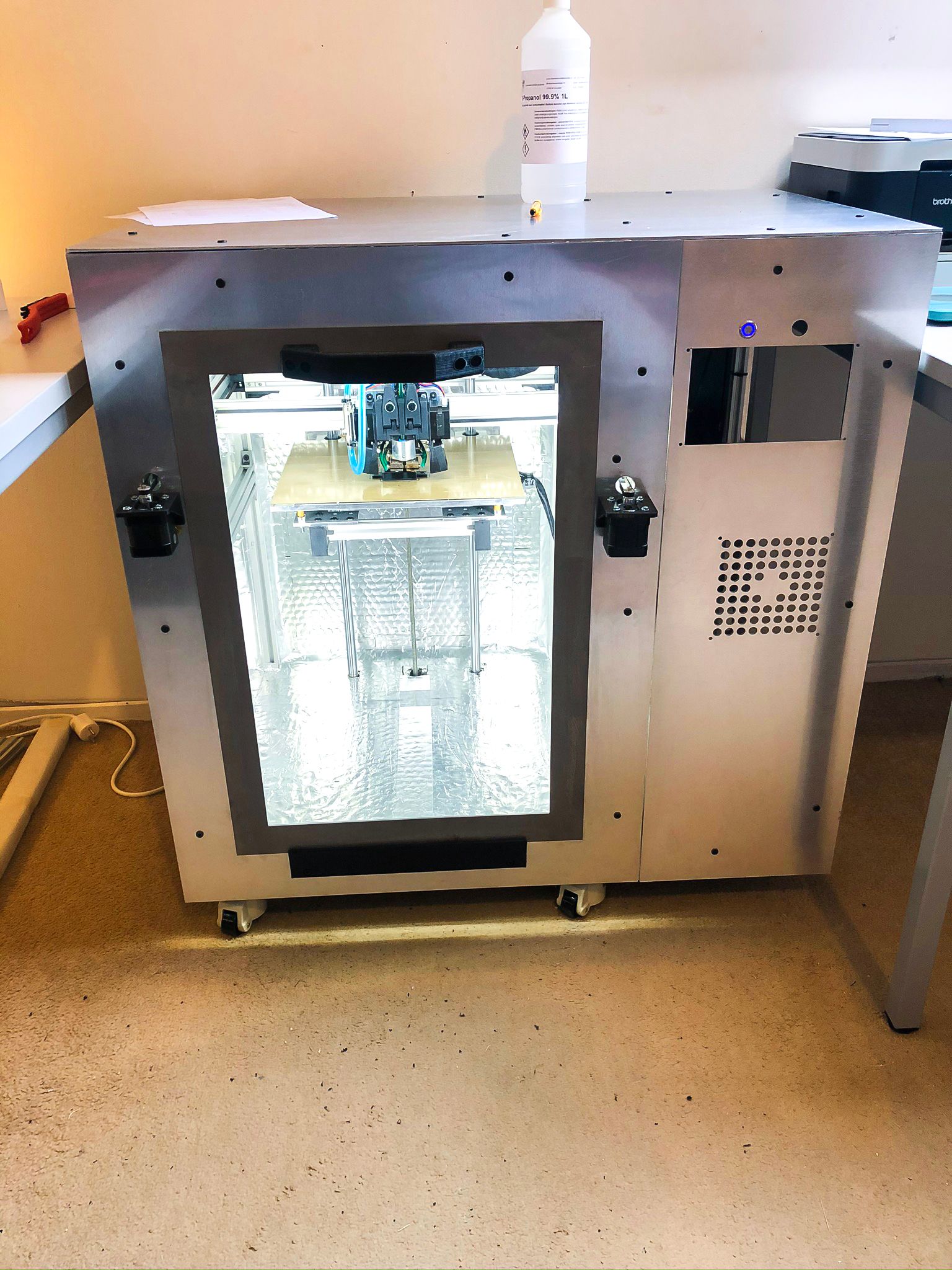

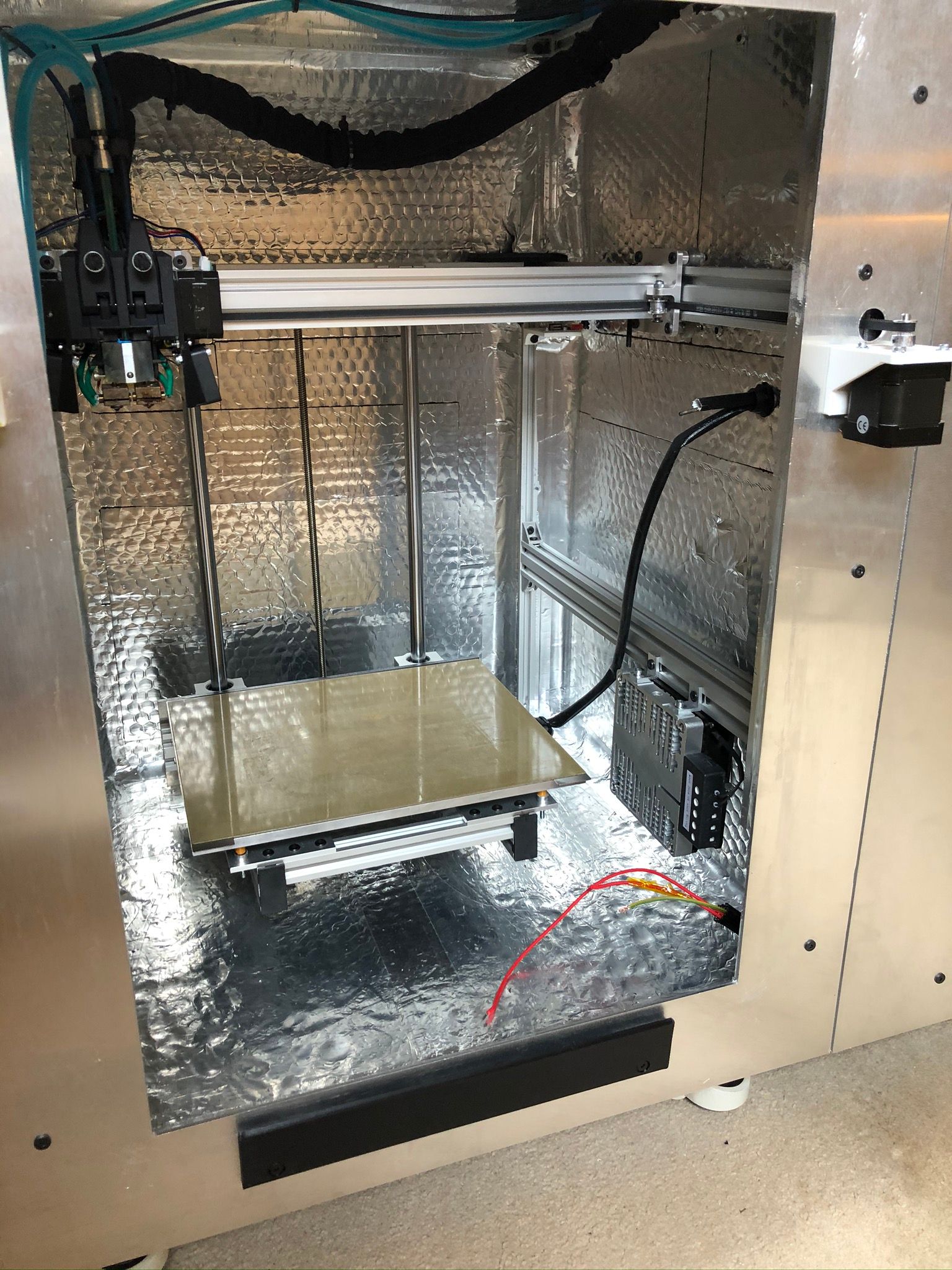

WIP CoreXY with heated chamber

-

@mrehorstdmd It has a lot of air coming out, I did get inspired by Raise 3D pro I have, and it has the same idea sort of, gives a lot of air - also this fan what I am using has a lot of pressure compared to Noctua or similar. I did a small video trying to show it with the lighter.

https://share.icloud.com/photos/0UQ3lXNX68oKFoiqHt2Zj_HAQ -

@felt342 Well it's all about static pressure, so if you've got that, you're all good.

-

@Phaedrux I think the exact same way that using 4 screws to level a print bed became popular. Someone made a mistake, posted it to the web, where others saw and copied it without thinking about it or testing it.

That video of the test with the fan ultimately led me to delete my reddit account. I had people getting nasty about it and claiming that it was impossible, even though anyone could have tested it with a taped up piece of paper. Those are the times we live in...

-

@mrehorstdmd I remember that thread actually.

-

-

Yeah, I am very happy what they do the job. I would be really disappointed if they will fail me, as they quite pricey 16 EUR each!

-

Busy summer and I have a couple of updates:

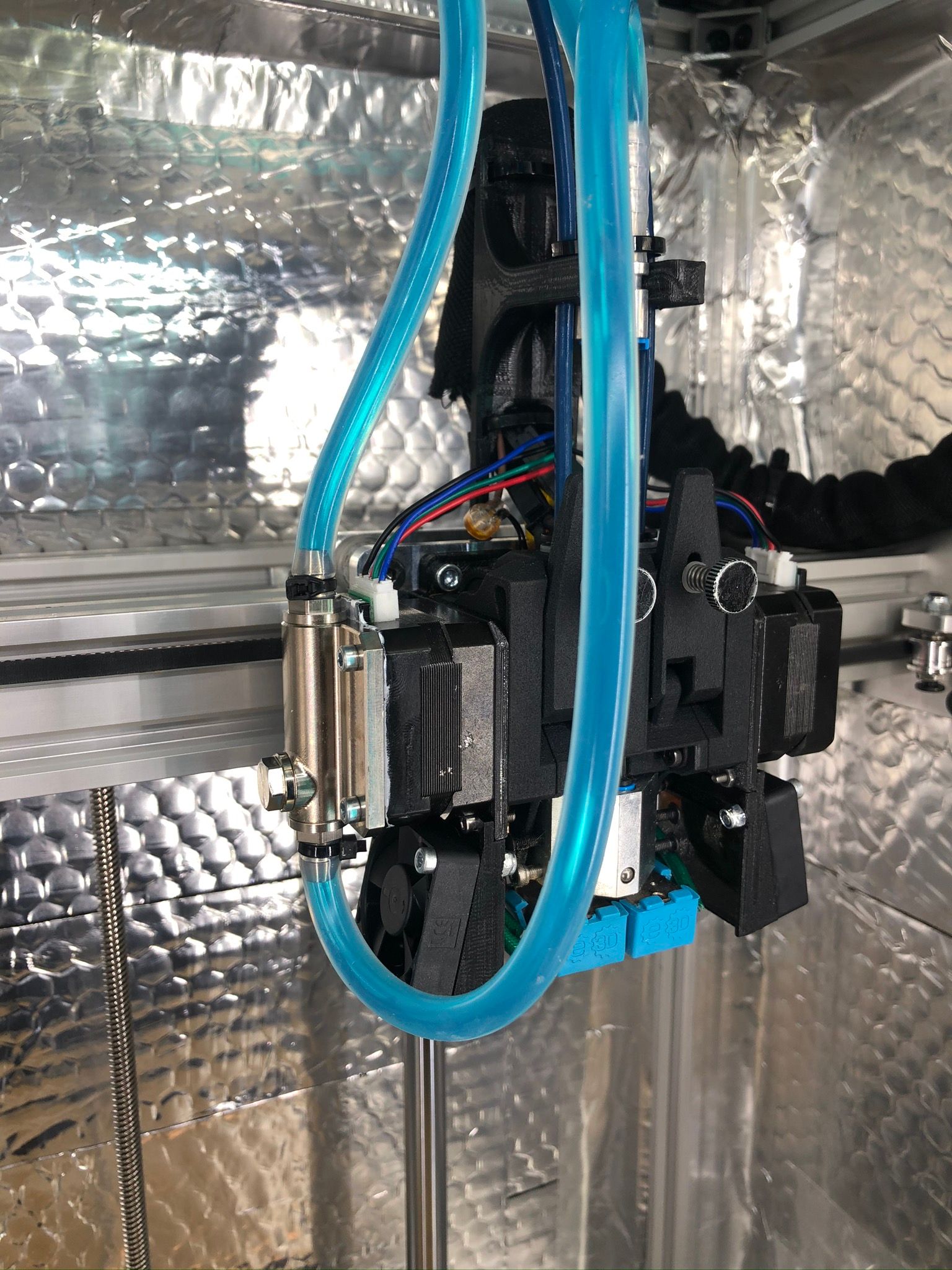

Water cooling for the extruder stepper, I couldn't touch it being printing nylon with 65 degrees chamber. So decide it would a good idea to link water to the stepper too, glad the connection was all there already for the hotend. I used the Dezy Design water block, seems working good and the motor casing in the same chamber now is barely warm.

And finally, I got a door, no more cardboard covering! Its a very simple one, just a 3mm steel frame and 5 mm polycarbonate sheet attached to it through heat resistant double side tape. The door holds on the magnets, which are also on the same double-sided tape behind the aluminum casing. From the bottom, there is ABS printed support. The door handle just quickly designed and printed from nylon.

Now I can really focus on the way to the heat chamber...

Cheers!

heers

heers -

..looks s(l)ick, clearly not messing about!

-

@bearer haha thank you!

-

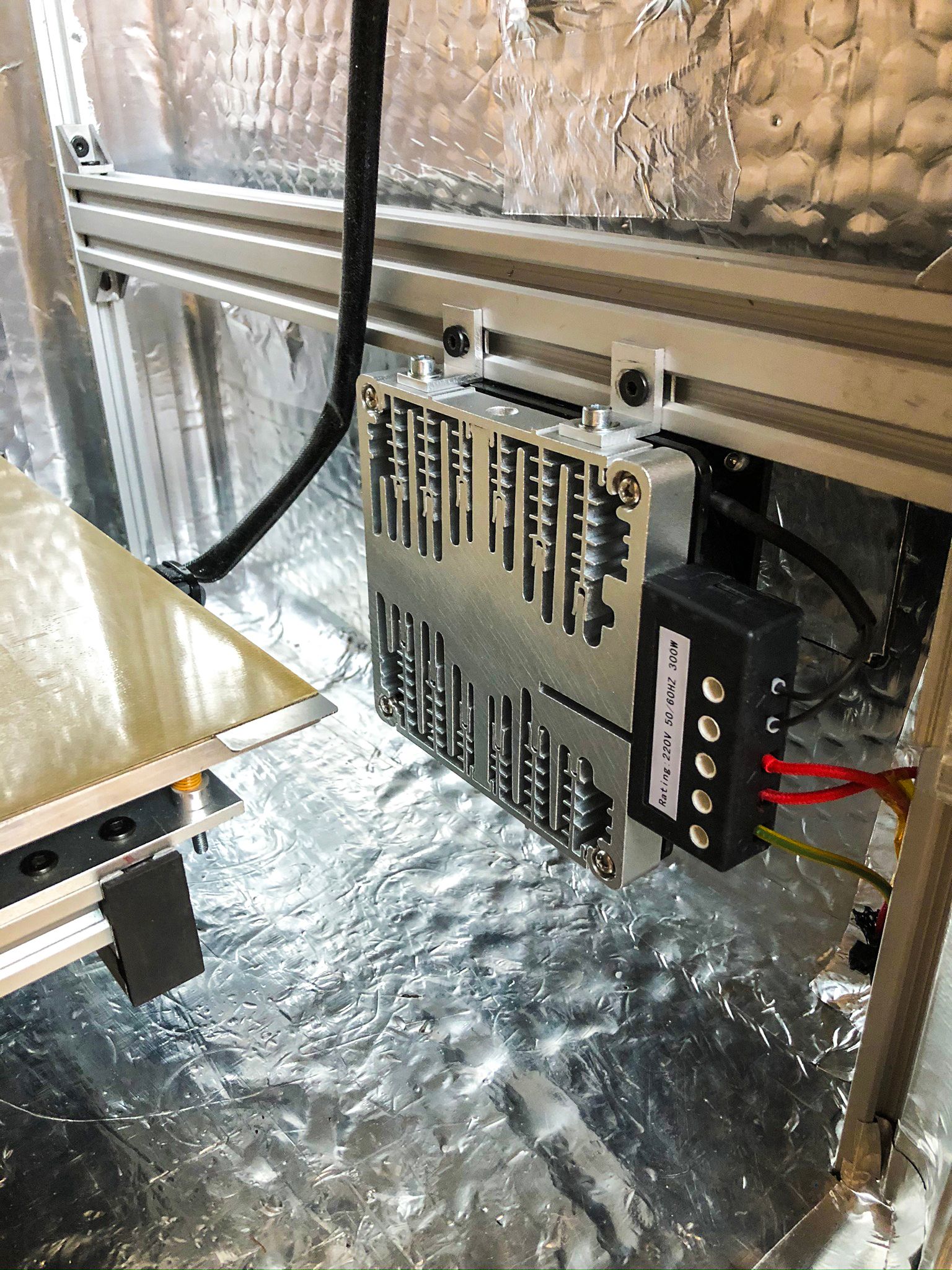

Okay, there I have a couple of new updates. I`ve been working on a heated chamber solution and found this one - https://szxinruite.en.made-in-china.com/product/vykEjoYlrwhx/China-Rhw-032-Industrial-PTC-Fan-Heater-for-Electric-Cabinet-with-UL-Thermostat-Heater-Temperature-Control-Heater.html

I did order 300W version, and it gives me a 55C evenly distributed heat chamber in 15 minutes also with enabled heated bed set to 75 degrees for printing ABS, which gives me zero warp with abs and no distorted first couple of 5mm due to set low bed temperature.

However as my plan was to get to 70C, I am thinking to order another same heater but rated to 600W or 800W and install it on the opposite wall and maybe on a bit different height. And hopefully, it will give me a reasonable speed till 70C.The nice feature of this heater is what it has integrated Temperature safety cut-out if the fan will die. The fan and fan casing made completely from steel.

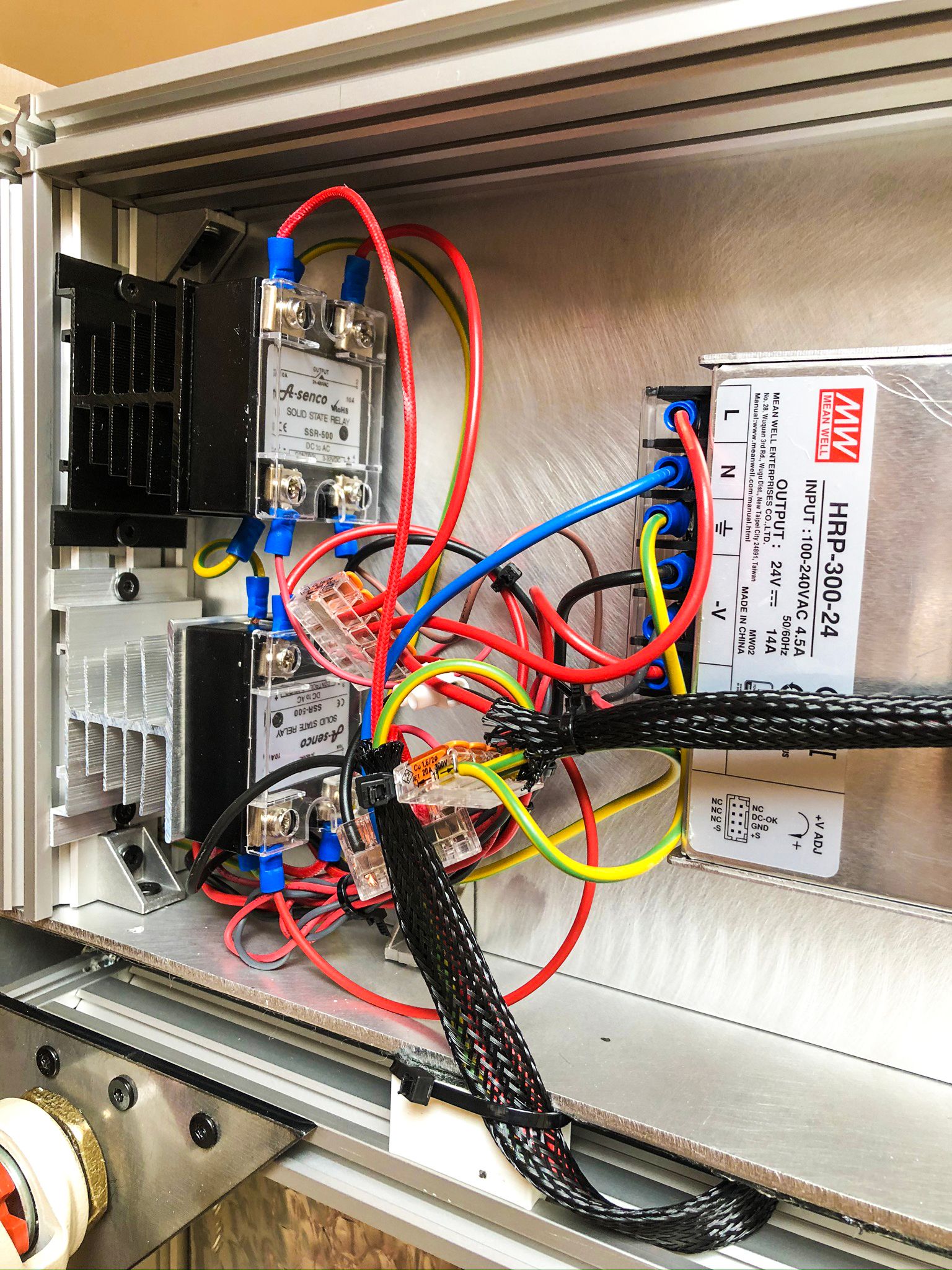

And a small esthetic addition to Z-axis, please see pictures! And I need to tide up the wiring here

Till next time!

-

I think I missed it but what is the bubble wrap looking liner you are using?

-

Hi I don't know the official type actually, I had a facility next to my house, and those guys were specialized on heating systems. They suggest me this foil - it is blend of resin and glass fiber and gives you deadening effect because of resin plus prevent heat transfer because of fibre glass. Similar what is used in a car for deadening wall to prevent vibrations and noise but there is without glass fibre. I got a pieces from them which they are throwing away

Works good!

Works good! -

This is sweet!