Extruder skipping predictably???

-

I thought it might be a gap between my hot end and the PTFE fitting not being tight, but I remedied that and it still skips... Im really confused as to why this would be happening...

Any help would be appreciated.

thank you -

I'd try a few things like heating the hot end to well above the range I normally use for printing and then extruder a good deal of filament to free air hoping to push through any blockage. Then I'd let it cool to ambient and then heat to 80-90c and do a cold pull of the filament from the nozzle hoping to pull out any remaining blockage.

If that didn't help I'd disassemble the entire extrusion system and inspect and replace any worn parts.

-

Please provide pictures of your complete hotend setup and a failed print. Be sure to include pictures showing your part cooling fan duct with regard to how air blows on the hotend.

Some questions

When it starts skipping does it stop extruding (printing air) or are you getting inconsistent extrusion? For example, does the print fail at that spot or are there gaps in the extrusion? Need pictures of the print.Does the extruder stop spinning or is the hobbed gear slipping on the filament? Is it making any weird noises?

Looks like the Nova has an all metal heat break. Not familiar with Nova but if you’re printing PLA, PLA typically has issues with all metal heat breaks. Have you tried contacting nova for assistance?

Are you retracting too much? Too much retraction on all metal heat breaks can cause clogs.

Is the part cooling fan turning on at that point and cooling the hot end too much? Have you pid tuned the hotend with the part cooling fan on? Do you have a sock for the hotend? Maybe make one out of ceramic insulation and kapton tape.

Have you checked your part cooling fan with the cup of water test?

What layer height, nozzle diameter and print speed are you using. Is the print speed increasing at the point of failure? Is your extruder gear tension tight? Is the gear loose on the extruder? The CR-10 extruder isn’t the best quality and could be slipping especially at higher print speeds.

-

Try changing (reducing) your filament retraction settings - saw that fixed a similar problem before elsewhere in the forums.

Sometimes hot filament will stick to the walls in the heat break and cause a ‘jam’ at repeatable points in a print. Reducing the retraction decreases the likelihood of this happening.

-

So its happened with multiple PLA filaments

2 different PETG filaments as well.

It has not yet happened on ABS, but i think thats more likely because I havent tried printing anything large with it yet. ABS prints have all been small.

It MAY be heat creep. I will try a larger ABS print now to see what happens.I dont have any pics of failed prints, but i know all the answers.

Part fan is a BAF https://store.3dpassion.com/collections/store/products/baf

The fan blows directly on the part and I suppose the hot end as well... However the hotend maintains its temps just fine... Its a great hotend in that regard. I have even ramped PLA up to 220c to see if it was potentially cooling pre maturely, but no... it still occured.WHen it skips (the first few times) it was about layer 20 of a large print, and it basically just skipped back, and missed a tiny stretch of extrusion. Yes, inconsistent extrusion. Eventually after a little while of this behavior it just clogs or stops extruding...

Hobbed gear slipped on the filament. Not making any odd noises except for when it skips.

I am friends with the creator of Nova. we are working on it. Trying some diff things... kinda stuck at the moment.

Too much retraction would be how much? I had it set at .6mm, and 2mm (because it oozed a bit much with .6). Doesnt seem to be too much retraction... too low retraction causes major oozing... I guess I could try VERY low retraction .5 for example and lower the temp a bunch on the Hot End to control the oozing.

Part fan has no impact. Its happened in layers 1, 2, 3 before cooling fan, or at layer 20 when the fan is on.

Never heard of the cup of water test.

Layer height .2 .5 mm nozzle, speeds vary from 20 - 100mm/s mostly 40-60 during this time where its happening. Speed up , slow down doesnt seem to impact things. Gear is not loose (ill double check tho).

I am more than willing to swap the CR10 extruder, IF i know its the cause.

-

@dunginhawk said in Extruder skipping predictably???:

I guess I could try VERY low retraction .5 for example and lower the temp a bunch on the Hot End to control the oozing.

I would recommend trying what you mentioned above. All metal hotends can be very sensitive to excessive retraction and can cause issues you're describing. Is it a bowden or direct drive? Do you have pressure advance configured?

Never heard of the cup of water test.

Here is a video from teachingtech that demonstrates the water test. https://youtu.be/xPvLKSClShc?t=247 It's not very scientific but can be helpful for getting an idea of the part cooling air-flow.

The filament temperature might be inconsistent if the part cooling fan is blowing on the side of the heat block where the thermistor is located. Recommend trying a print with the part cooling fan off to see if it helps. If it does you might need to redirect the part cooling fan duct and or get a sock for the heat block.

-

Retraction didnt seem to make a difference... 0 retraction or 5mm. no difference.

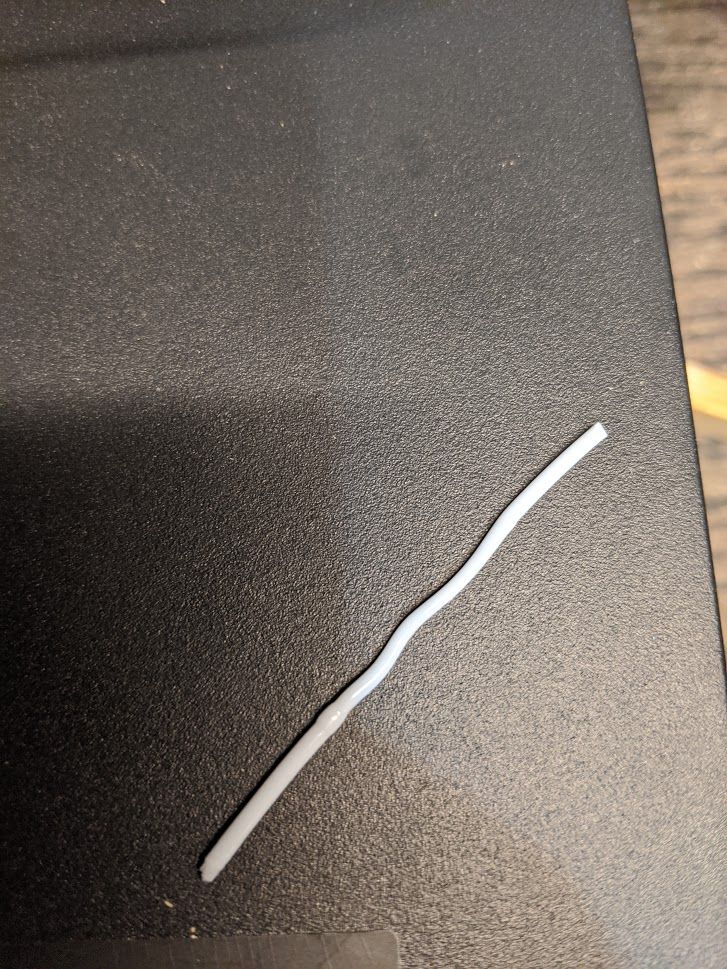

This is a picture of the issue in a nut shell. so I can manually push filament through, but as soon as I stop. then start a real print, its like the extruder itself cant push the filament through. Could I need a new gear? How likely is that?

You can see a bulge right there too, i THINK that is a ring inside the bowden fitting on the top of my hot end. if so, the heat is WAY higher than it should be.THoughts?

-

Not much info provided but if that’s the filament pulled out the top of the hotend, that’s not good. Looks like the filament is getting stuck in the hotend and causing it to buckle in the Bowden tube.

I think you’re dealing with two issues. The major issue is the filament is getting stuck in the hotend which leads to the extruder slipping and grinding on the filament.

Recommend looking into an oiler. Do a google search, It’s called seasoning the hotend. This will leave a layer of baked on oil inside the hotend and help make sure the filament doesn’t get stuck. Use regular canola cooking oil and LIGHTLY soak a small piece of a rag or microfiber towel. Wrap the towel around the filament before it enters the extruder. I believe you should only need to do this for a quarter of the spool.

I also think the extruder has slipped enough to wear out the gear. It might need replacement but try seasoning first.

Need pictures I asked for earlier if you need further assistance.

-

That bulge you have on that filament, that's hotend issue. That looks rather nasty as it's very far from the melt zone!!

Having a better push mechanism (e.g. bondtech dual grip..) will just delay the inevitable and the issue will be postponed. have never seen that hotend 1st person (only images) so can't say nothing about it but for a workaround, for starters, you can try printing faster while disabling retraction completely. Yes, it will string as hell but that's a first thing to try.

Disabling retraction limits the bidirectional movement of the filament that's main reason for "bulging" and increasing print speed increases filament movement speed hence decreases the heat creep as filament is moving the heat down.. -

wrt oiling and seasoning, I'd point you to the

https://www.sublimelayers.com/2017/06/friends-dont-let-friends-use-oil.htmldunno what type of nozzles the nova uses but the new X nozzles from e3d feature coating that repel plastic so are extremely slippery for plastic and leave perfect top layer while enabling much sharper corners than normal nozzles. if you can put e3d nozzle in the nova you should.

but looking at that pic, your issue is not with the nozzle but with the throat/heat break and that normally means you need to look at the hotend design more carefully

-

I think i have it resolved... THINK.

I have a line of code M106 P1 B0 X0.6 S0.3 I0 F100 H1 T120 C"Hotend" ; Set fan 1 (extruder fan) value, PWM signal inversion and frequency. Thermostatic control is turned ONbasically that turns on the fan when the hotend gets to 120C.

However that S.03 only runs it at a slow speed. Changing the S.03 to S1 made a HUGE difference.

Before I shot with a laser thermometer the heat sink at nearly 60 degrees C.

After the change to the fan speed, 27 C.Was just some confusion with my friend (inventor of nova) on different models of fan I got vs some others. Simple mixup. Ill report back on whether this is the fix for sure. but 1 hour in to a PLA print it appears to be the case.

-

so yeah, i think that fixed the issue... Ive been printing most of the day now without issue... Im doing retraction testing now...