CoreXY movement calibration

-

Hi,

The first thing I would check would be the Z axis. It seems to be moving inconsistently.

Frederick

-

@droftarts said in CoreXY movement calibration:

@marnog Glad you have made progress!

Looking at that print, it's hard to tell what's happening. In some places the layers look like they are bulging out both left and right, but in others they look like they've moved in XY (bulge on one side, indent on the other). The main thing to look for is bulges that match on both sides (which would be Z problems or extrusion inconsistency), whereas layer shifting would indicate an XY problem (either with nozzle placement or the bed shifting in XY). How tight are your belts (do you get a 'twang' from them) and are they equally tight?

Ian

Ian,

It looks more like layer shifting than an extrusion inconsistency - it looks more like a wobble than Michelin Man effect. I've printed the same part on another printer with the same filament and it looks much better, so I doubt that it would be inconsistent filament diameter either.

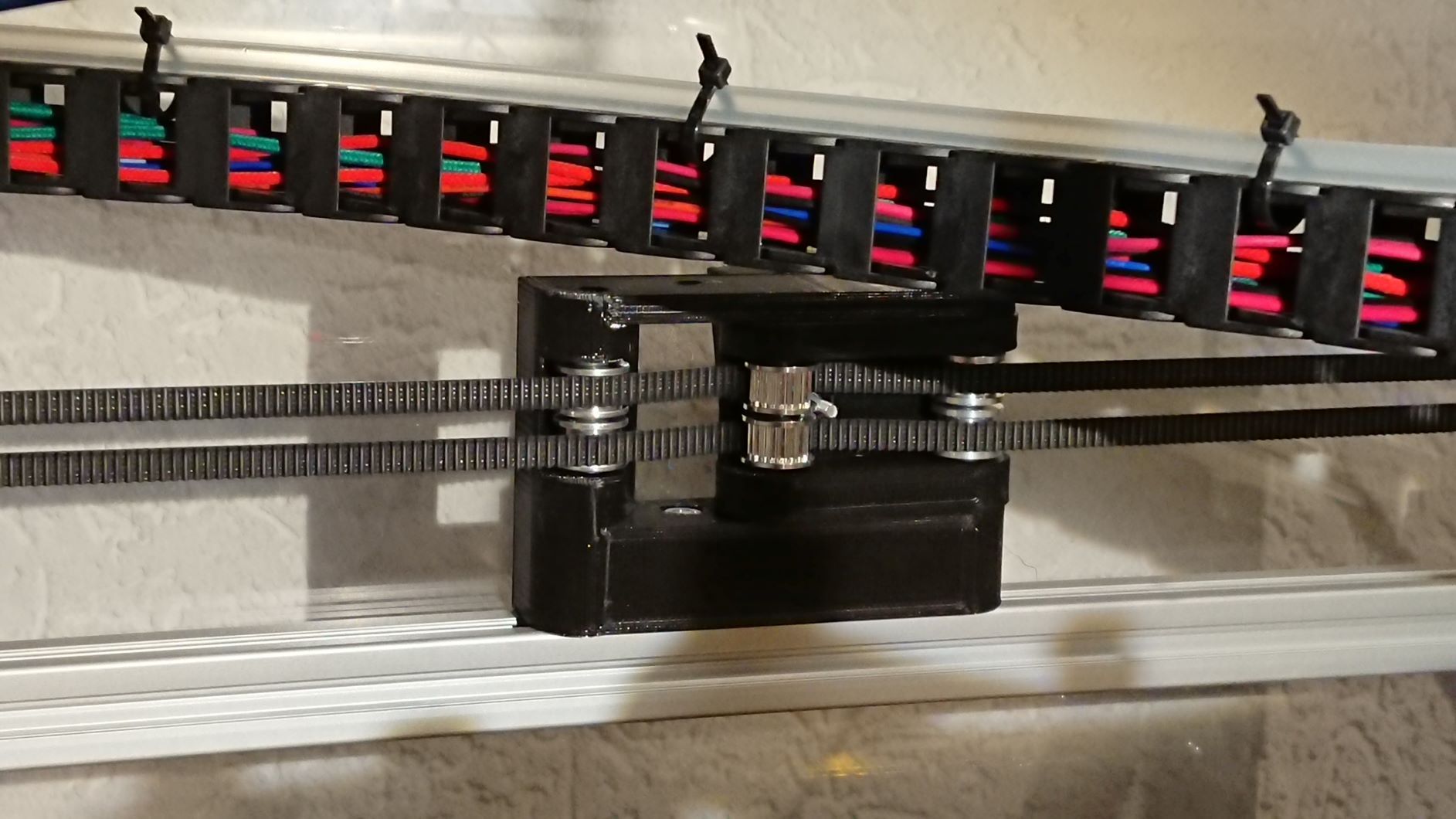

My belts are both the same length, and I have a tensioner with the intention (cough) of applying equal tension on both belts.

To be honest, the belts aren't very tight. In the middle of the longest section of belt (490mm) I can pull the belt about 16mm to the side from a resting position (32mm side to side). I get a twang if I use my imagination... In being overly careful not to over tighten the belts, I might have them too loose. -

@fcwilt said in CoreXY movement calibration:

Hi,

The first thing I would check would be the Z axis. It seems to be moving inconsistently.

Frederick

Hi Frederick,

I have both leadscrews running from 1 stepper - trying to avoid inconsistencies between the leadscrews. The setup is very very similar to an FT-5.

How would you check the Z axis? -

@marnog said in CoreXY movement calibration:

To be honest, the belts aren't very tight. In the middle of the longest section of belt (490mm) I can pull the belt about 16mm to the side from a resting position (32mm side to side). I get a twang if I use my imagination... In being overly careful not to over tighten the belts, I might have them too loose.

I'd guess this is the most likely reason, particularly as you say it's a wobble, not 'Michelin Man' (will have to remember that one) effect. From what I understand, and I don't have a CoreXY myself, the belts need to be quite tight. The relative tightness between the two sides also squares up the X gantry.

Have a read of @mrehorstdmd excellent blog post on the whole subject: https://drmrehorst.blogspot.com/2018/08/corexy-mechanism-layout-and-belt.html

His advice on belt tension is a long way down the page:

How much tension is enough? Unfortunately, that's hard to say. You can buy instruments that measure belt tension by pushing on a span of belt and measuring the deflection, but without any specs on the belts most people use, having a number isn't all that useful. Fortunately, belts work pretty well as long as you take out the slack. Some people pluck the belts like guitar strings to decide if they're tight enough and equal tension, but the real test of relative tension is the squareness of the X and Y axes, regardless of the absolute tension in the individual belts. So get them tight, but not too tight, and make sure the X and Y axes are square, and you should be fine.

In my RepRapPro days, we used to advise the following belt tension, though this is on a Cartesian printer, but with a similar 300-400mm belt span (make sure you 'twang' the longest section of belt that doesn't change length):

When you twang the bottom belt, which has the longest uninterrupted span, a just-audible note should be heard. For reference, the note of the lowest string of a bass guitar is suitable. This is the bottom ‘E’ string; search online for a bass guitar tuner if you need an example.

http://reprapltd.com/reprappro/documentation/ormerod/y-carriage/index.html#Y_belt_tensioning_and_carriage_slippingI'd say the above was the 'minimum' tightness the belts should be.

Ian

-

@droftarts Yeah, discussing belt tension is very much like discussing how long a piece of string is with everybody having their own piece of string.

With your post in mind, what I'll do is just tighten up the belts a bit, and I'll print something similar to the model that I had issues with (just a bit thinner to save some material) and I'll progressively tighten the belts further to see if I get an improvement.

Thank you for your post and your advice! I'll post my results. -

Gates makes a phone app that listens for the oscillation of a plucked belt. Fifty to Sixty HZ seems about right for CoreXY, with the caveat that the belts MUST be set to square the printer, and that could require quite a bit of difference.

50 to 60 Hz is incredibly tight... much tighter than I would have ever set them without the app. Be sure you have actual glass reinforced belts. I've pulled others apart.

-

@Danal said in CoreXY movement calibration:

Gates makes a phone app that listens for the oscillation of a plucked belt. Fifty to Sixty HZ seems about right for CoreXY, with the caveat that the belts MUST be set to square the printer, and that could require quite a bit of difference.

50 to 60 Hz is incredibly tight... much tighter than I would have ever set them without the app. Be sure you have actual glass reinforced belts. I've pulled others apart.

Thanks, I'll check it out. Only thing is that I'm not using genuine Gates belts, I bought "GT2x6 mm Kevlar-reinforced timing belt". Not sure if it'll make a difference, but I'll try the Gates app for reference.

Using the app, to what frequency did (or would) you tune your belts? -

50 to 60 Hz

-

@Danal 50-60 Hz over what span of belt? Shorter spans will "ring" at higher frequencies...

-

@mrehorstdmd said in CoreXY movement calibration:

@Danal 50-60 Hz over what span of belt? Shorter spans will "ring" at higher frequencies...

True. The people who told me to do that did not specify... I did it over the longest span I could find, on a corexy that has about a 350x350 bed, and corresponding frame.

It seems really tight to me. Could be a spurious data point. The printer does print well, though.

-

I would think there would be some spec on tension based on elongation of the belt. If it were something like 1%, over a 300 mm span, a 2mm pitch GT2 belt should have 148.5 teeth (or is the belt made so that when it is ideally tensioned the pitch will be 2 mm???)

-

@marnog When tensioning belts by ear, the lower E string of a bass guitar is 41.204 Hz, the A is 55 Hz, and the D is 73.416 Hz. For example sounds, see/hear here https://www.fender.com/online-guitar-tuner/bass-guitar-tuning/ or https://www.musicca.com/bass-guitar. Frequencies are here https://pages.mtu.edu/~suits/notefreqs.html

But as @mrehorstdmd rightly says, the frequency the belt rings at will depend on the span of the plucked 'string'. Same with 'deviation', ie pushing the belt with particular pressure and measuring how far it moves laterally. The belts (old-school 5mm white T2.5) on my Cartesian machine seem to be: X, 400mm span, G flat first octave (46.25 Hz); on Y, 320mm span, F second octave (87.31 Hz). X does feel a fair bit looser (should probably tighten it!).

A quick googling brings up a few options for measuring belt tension, of which this seems to be the best/most relevant, and has options for measuring both by frequency and by deflection: https://www.linearmotiontips.com/how-to-measure-synchronous-toothed-belt-tension/

Using their frequency formula of Static Tension = 4 x Hz pow 2 x L(m) pow 2 (ignoring belt weight and width as they are the same and I don't have numbers for them), I get

T(X) = 4 * 46.25 pow 2 * 0.4 pow 2 = 1369

T(Y) = 4 * 87.31 pow 2 * 0.32 pow 2 = 3122Or perhaps to put it another way, to match my Y axis I should tighten my X to:

sqr ( 3122 / (4 * 0.4 pow 2) ) = 69.84 Hz = C#/D flat second octaveThat sounds about right. Maybe. Or it could all be nonsense! Anyone care to calculate their belt tension? Maybe a new thread...

You should be okay if the span you are 'twanging' is the same length on both belts, though, and then it's a matter of getting them tight enough to stop layer shifting.

Ian

-

@mrehorstdmd said in CoreXY movement calibration:

I would think there would be some spec on tension based on elongation of the belt. If it were something like 1%, over a 300 mm span, a 2mm pitch GT2 belt should have 148.5 teeth (or is the belt made so that when it is ideally tensioned the pitch will be 2 mm???)

I like this thought. This would be interesting to know.

@droftarts said in CoreXY movement calibration:

A quick googling brings up a few options for measuring belt tension, of which this seems to be the best/most relevant, and has options for measuring both by frequency and by deflection: https://www.linearmotiontips.com/how-to-measure-synchronous-toothed-belt-tension/

Using their frequency formula of Static Tension = 4 x Hz pow 2 x L(m) pow 2 (ignoring belt weight and width as they are the same and I don't have numbers for them), I get

T(X) = 4 * 46.25 pow 2 * 0.4 pow 2 = 1369

T(Y) = 4 * 87.31 pow 2 * 0.32 pow 2 = 3122Or perhaps to put it another way, to match my Y axis I should tighten my X to:

sqr ( 3122 / (4 * 0.4 pow 2) ) = 69.84 Hz = C#/D flat second octaveThat sounds about right. Maybe. Or it could all be nonsense! Anyone care to calculate their belt tension? Maybe a new thread...

You should be okay if the span you are 'twanging' is the same length on both belts, though, and then it's a matter of getting them tight enough to stop layer shifting.

Ian

This is interesting. I'm going to try this. The calculation can also be tested with a single tensioned belt, and the different sections of it between pulleys and idlers.

Thanks Ian! -

@marnog said in CoreXY movement calibration:

Hi Frederick,

I have both leadscrews running from 1 stepper - trying to avoid inconsistencies between the leadscrews. The setup is very very similar to an FT-5.

How would you check the Z axis?Without actually having that print in-hand it's hard to be sure. In some places it looks like it is bulging out on both sides at the same place. Is that correct or just a issue with trying to judge by the photo?

Frederick

-

@fcwilt said in CoreXY movement calibration:

@marnog said in CoreXY movement calibration:

Hi Frederick,

I have both leadscrews running from 1 stepper - trying to avoid inconsistencies between the leadscrews. The setup is very very similar to an FT-5.

How would you check the Z axis?Without actually having that print in-hand it's hard to be sure. In some places it looks like it is bulging out on both sides at the same place. Is that correct or just a issue with trying to judge by the photo?

Frederick

I understand what you mean. The model is not perfectly cylindrical, so it's hard to see in the photo. And the model has 4 prongs/pillars/posts/towers and I can't tell if the bulging deviates in the same direction on all 4 upright parts.

But is does look like the bulging is to a side (a bulge with an indentation on the opposite site). Not a squishing, or Michelin Man effect. -

@marnog said in CoreXY movement calibration:

But is does look like the bulging is to a side (a bulge with an indentation on the opposite site). Not a squishing, or Michelin Man effect.

Then I would suspect some problem with the X/Y system causing layer shifting. I had that but some work with changing belt tensions (mostly trial and error) took care of the problem.

Frederick

-

What are your Z screws setting on? It looks to me like inconsistencies in your Z axis causing a lean of the whole part. It looks like it gets worse as the part gets taller. I had similar problems when my Z screws were coupled directly to the stepper shafts, which had endplay, and inconsistent springiness that could not be controlled. As one screw advanced less than the other, the bed tilted and the part leaned just a bit causing a very similar affect. I think it happened lower in the print as well, but the error was amplified as the part got taller, and seemed to gradually appear rather than start late in the print.

Do your screws rest in a bearing meant for thrust load? It looks pretty good from the pics, but I cant tell whats at the bottom end of the screw.

(Mine ended up on pin roller thrust bearings, but my beds get to weigh 40-50 lbs empty)