CoreXY movement calibration

-

@mrehorstdmd said in CoreXY movement calibration:

Are the "flatter" sides of the circles on opposite sides of the circles? Are they aligned with the axes or at 45 degrees?

Mark, the flatter sides are on opposite sides of the circles along the Y axis.

@fcwilt Frederick, the pulleys are properly secured to the motor shafts with grubscrews, and the grubscrews are secured with Loctite 222. And all the idler pulleys are on shafts. The flat spots look like a sure result of backlash (especially for where they are located), but I have checked, no backlash anywhere.

@Danal Thank you, I'll have a look at the carbon drive app.

@deckingman & @DaBit Because of the increased torque factor and the increase in positional stiffness is why I am having such a hard time understanding why I'm getting the inaccuracies that I'm getting. A & B axes are close to spot on, but then I'm getting the discrepancies in X & Y. Everything points to some form of backlash, which I cannot find. I'm using bowden extrusion to a single hotend. The heaviest items on the X axis is a copper heatblock and a Hiwin MGN12 rail and carriage. So it is by some distance not the heaviest setup.

@Veti Igus (or rather their reps) claims that all their products are suitable for 3D printing. Yes, there is a gap to allow movement, but the way that I have them set up (along with the CoreXY system) would result in side to side movement, and not along its direction of intended travel. I have them on the Y axis, so any backlash should be in the X axis. For more info: https://www.igus.com/product/920

-

@marnog said in CoreXY movement calibration:

claims that all their products are suitable for 3D printing...

My CoreXY machine is a modified DBOT - all wheels running of v-slot extrusions, except for the Z axis. I had my doubts but it seems to work.

So it doesn't seem likely that those rails you have are the problem but who knows.

However, if all else fails perhaps you need to replace them with typical linear rails just to be sure.

Frederick

-

@fcwilt Frederick, I cannot tell you how many times I've had genuine Hiwin rails in a webshop cart, only to cancel the order when I take my bank account's feelings into consideration. And the fact that I will have to change all the parts of the XY kinematics to fit the different rails.

Because the greatest error is on the Y axis where I'm using the Igus rails, I am very distrusting of them. But from double checking the system time and time again, and logical reasoning tells me that they shouldn't be the cause of the problem. I'm running out of ideas. -

@marnog said in CoreXY movement calibration:

@mrehorstdmd said in CoreXY movement calibration:

Are the "flatter" sides of the circles on opposite sides of the circles? Are they aligned with the axes or at 45 degrees?

Mark, the flatter sides are on opposite sides of the circles along the Y axis.

That sounds like backlash in one of the axes to me. If the flats are approximately parallel to the X axis, it indicates that the Y axis isn't moving as it should. If they are approximately parallel to the Y axis, the X axis is the problem.

Does the problem occur at all speeds? What is the acceleration setting?

-

@mrehorstdmd said in CoreXY movement calibration:

That sounds like backlash in one of the axes to me. If the flats are approximately parallel to the X axis, it indicates that the Y axis isn't moving as it should. If they are approximately parallel to the Y axis, the X axis is the problem.

Does the problem occur at all speeds? What is the acceleration setting?

Exactly, it sounds like a backlash issue to me too. Or even flex in the system. But the way that the linear guides/rails allows movement contradicts the notion of backlash. The Y axis linear guides/rails have no restrictions in the Y axis of travel, which means there is nothing to measure play against which would translate to backlash. Only thing relative to that might be binding in the rails, restricting movement, but everything moves freely. The belts are under an equal amount of tension. All the idler pulleys rotate freely without play in the shafts.

The problem occurs at all speeds. I increased the speed to see if it exaggerates the problem, but it seems to be constant. It looks like one of the motors has a higher acceleration than deceleration when changing direction.

My current acceleration and jerk settings:

M566 X720.00 Y720.00

M201 X2000.00 Y2000.00Might I be tuning the 'steps per mm' wrong? When printing a 140mm diameter octogon, I'm tuning the 'steps per mm' to get as close as possible to 140mm in the diagonal A & B axes. Adjusting M92 X & Y accordingly.

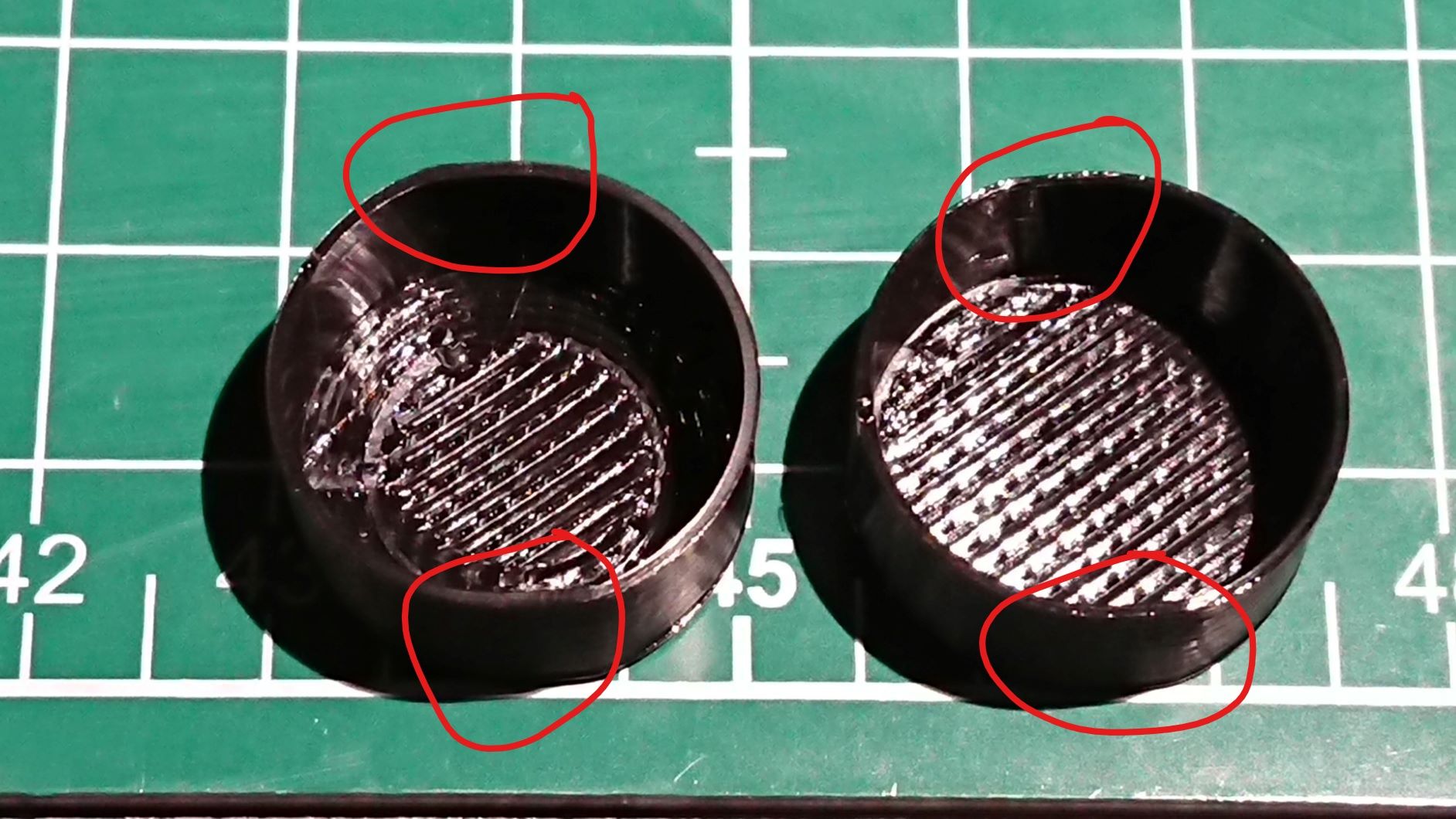

These are @mrjoneskod's photos, but I'm getting exactly the same elliptical deformation with flat spots in my prints. (I just don't have such a clear photo of my prints at the moment.) @mrjoneskod's problem was resolved by replacing a bushing that had backlash, but that is on an entirely different kinematics system - Ultimaker style

https://forum.duet3d.com/topic/9305/circles-eliptcal-with-fla-segments-on-the-x-direction

-

Do you get the same flat spots regardless of where on the bed you print the object?

Frederick

-

@fcwilt said in CoreXY movement calibration:

Do you get the same flat spots regardless of where on the bed you print the object?

Yup. I printed all over the bed to see if I might have binding in certain sections of the linear rails, but it happens everywhere. It is much more noticeable in smaller circles than bigger ones.

-

-

@fcwilt said in CoreXY movement calibration:

And the position of the flat spots remains the same?

Always at the MAX Y and MIN Y of the circles.

-

Maybe I missed it somewhere but how do your squares print. Have you printed some sort of calibration square both aligned with your axis and one at 45 degrees from x/y?

-

@antlestxp I printed an octagon with a diameter of 140mm. This gives me an object with 140mm in X, Y, A, and B. With the most recent ones that I have printed I got the following run-out / deviation over 140mm:

A (diagonal): +0.015

B (diagonal): +0.011

X: +0.121

Y: -0.177 -

can you scale it down to 50% to see if the deviation stay constant or scale down as well.

-

@Veti said in CoreXY movement calibration:

can you scale it down to 50% to see if the deviation stay constant or scale down as well.

I'll give it a try. I hope that I can get accurate measurements. The smallest deviation is 0.011mm. Differences on that scale would result in large jumps in percentages. I'll try, and report back.

-

I am no photographer. Below are 2 of my own prints: 20mm diameter cylinders. Both printed in an anti-clockwise direction. On the left is the cylinder printed in vase mode (spiralized outer contour), and on the right is the cylinder printed in sequential 0.2mm layers. Unfortunately I cannot get a photo that looks like what I see. Hopefully you can see the flat spots and eliptical deformation that I'm referring to.

-

Hi,

Do those non-standard rails have any side-to-side play?

Frederick

-

@fcwilt said in CoreXY movement calibration:

Do those non-standard rails have any side-to-side play?

they must have otherwise they would not be able to slide as no ball bearings are involved.

-

@Veti said in CoreXY movement calibration:

@fcwilt said in CoreXY movement calibration:

Do those non-standard rails have any side-to-side play?

they must have otherwise they would not be able to slide as no ball bearings are involved.

Enough to create the apparent backlash that seems to be the source of the problem?

Frederick

-

that is the question.

i just want to see if the backlash stays the same on the smaller print.

0.1mm is a movement you will be hard time identifying by inspection.maybe disconnect the x carriage on one side and measure the angle you can twist the carriage in either direction.

-

Maybe put this in a gcode file:

G28 G90 G1 X100 Y100 Z1 F6000 G91 F30 G1 Y0.1 G1 Y-0.1 G1 Y0.1 G1 Y-0.1 (Repeat the above sequence many, many times) G1 Y0.1 G1 Y-0.1 M30And watch everything mechanical carefully.

-

@fcwilt said in CoreXY movement calibration:

@Veti said in CoreXY movement calibration:

@fcwilt said in CoreXY movement calibration:

Do those non-standard rails have any side-to-side play?

they must have otherwise they would not be able to slide as no ball bearings are involved.

Enough to create the apparent backlash that seems to be the source of the problem?

Frederick

They do, by which I mean they must. But not noticeable. And then @Veti said in CoreXY movement calibration:

0.1mm is a movement you will be hard time identifying by inspection.

Do you think that play in the X direction would cause the defect and run-out / deviation in the Y direction? I would like to think that the CoreXY configuration would keep that kind of play in check. I printed my "calibration octagon" at 50% scale. I'll measure it and report back.

@DaBit said in CoreXY movement calibration:

Maybe put this in a gcode file:

.......@DaBit I'm going to try this, and also in the X direction to see what it does. See if there is as much noticeable play in the X direction.