https://youtu.be/pYNwgpBxzKA <- 50mms? print on carbon rails with igus bushings with stealthchop

https://youtu.be/DWFjq-QLerY <- on nippon bushings still stealthchop

https://youtu.be/pYNwgpBxzKA <- 50mms? print on carbon rails with igus bushings with stealthchop

https://youtu.be/DWFjq-QLerY <- on nippon bushings still stealthchop

nope. you can use a step down regulator for your 12v fans but the hotend must use a 24v cart. You will nuke your 12v cart on 24v and you can't use a step down on it.

this would be nice to see working again so I can avoid the location of the magnets I have under my PCB bed.

i have seen the tronXY in person. its not a bad printer to get started with but you will end up replacing bearings and printing some upgraded parts to increase rigidity. with your budget it might be easier to scratch build something like a hypercube. there is a good amount of documentation to get you started and a pretty good community behind them. i have a 30x30x30 and absolutely love it. your biggest hurdle will be getting the printed parts unless you have a printer already you can use. 500x 500 shouldn't an issue with 10mm rails any bigger and you will need to find a more ridged motion system if you plan on printing quickly. you can find build instructions and the base set of parts on thingiverse. there is also a facebook group.

There are 2 error states for the bltouch. a rapid flash is a mechanical issue. either the magnet is out of place when retracted or there is an issue with it moving. there is a a slower red flash that is for a wiring or connection error. either its wired wrong or it detects a random short. this is for the v2 v2.1 as far as i know.

do your axis move freely with out the motors attached? i run my corexy at 850 with no skipped steps. the motors stay cool to the touch. you may just have too much mechanical resistance. that will heat up the motors along with the need of high current.

I'm not ashamed to say the TriangleLabs bmg clones work the same as the originals. I bought the clone to see how I would like them. Then bought the originals to support the company that actually put in the RnD. Sorry to say they print exactly the same. I will always say support genuine products but if cost is a limiting factor, majority of the stuff coming out of trianglelabs is top notch. Side note, the TL e3d titan clones are actually better than the original e3d products.

Ok guys, a conclusion. I found I was chasing 2 issues. Issue 1, yes the mosfet is bad. I removed it and tested it. It gave me no love. Like someone said b4, these usually fail hot no open. Kinda strange but oh well. Issue 2, the back up heater cart I used was also bad. A while back I had one stop working and instead of throwing it away I kept it to figure out why it wasn't working.

Thanks for the help. Truly appreciate it!

I'm thinking about going back to dual extrusion. I had it working when I was on Marlin but wasn't ready to try and figure out how to get the duet working and trouble shoot multi printing. Would you be willing to share your dual config files. It would give me a head start.

is there a way to swap out the layer chart for the web cam feed?

@dmbgo you want to be above 60 for the enclosure but not to high if printing small parts. Goal is to have the layer cool just enough to start to become solid but not enough that it shrinks. You want to avoid using the fan because that will cool to rapidly. I will usually print multiple objects when I print abs. My enclosure usually hovers around 70 degrees. Did you ever try printing 2 objects to increase your layer times?

is your bed level? looks like the nozzle is closer on one side of the print than the other. a bad first layer can make trouble for the rest of the print in abs, especially if you are printing small items with short layer times. I would try leveling the bed so the first layer looks perfect and printing 2 test cubes instead of one to give each layer enough time to cool off before the next layer hits. I forgot to ask how ridged is your carriage? is there any play or slop in any direction?

Ok guys, a conclusion. I found I was chasing 2 issues. Issue 1, yes the mosfet is bad. I removed it and tested it. It gave me no love. Like someone said b4, these usually fail hot no open. Kinda strange but oh well. Issue 2, the back up heater cart I used was also bad. A while back I had one stop working and instead of throwing it away I kept it to figure out why it wasn't working.

Thanks for the help. Truly appreciate it!

Got it. I will pull it all apart again before I continue to test.

@Phaedrux nope, I'm just an idiot. After the first fault, I reset the board at it looks like my config reverted to using e0 instead of e1... e1 still lights up, but light for e0 is still dead. It still lights up even when it faults. I will yank the thermistor and see if that gets me going.

@Phaedrux I will pull it and toss another one in. What do you think is causing the heater Leds from coming on? Heater 2 was working this morning but as of right now, nothing.

The light on the second heater is dead now.

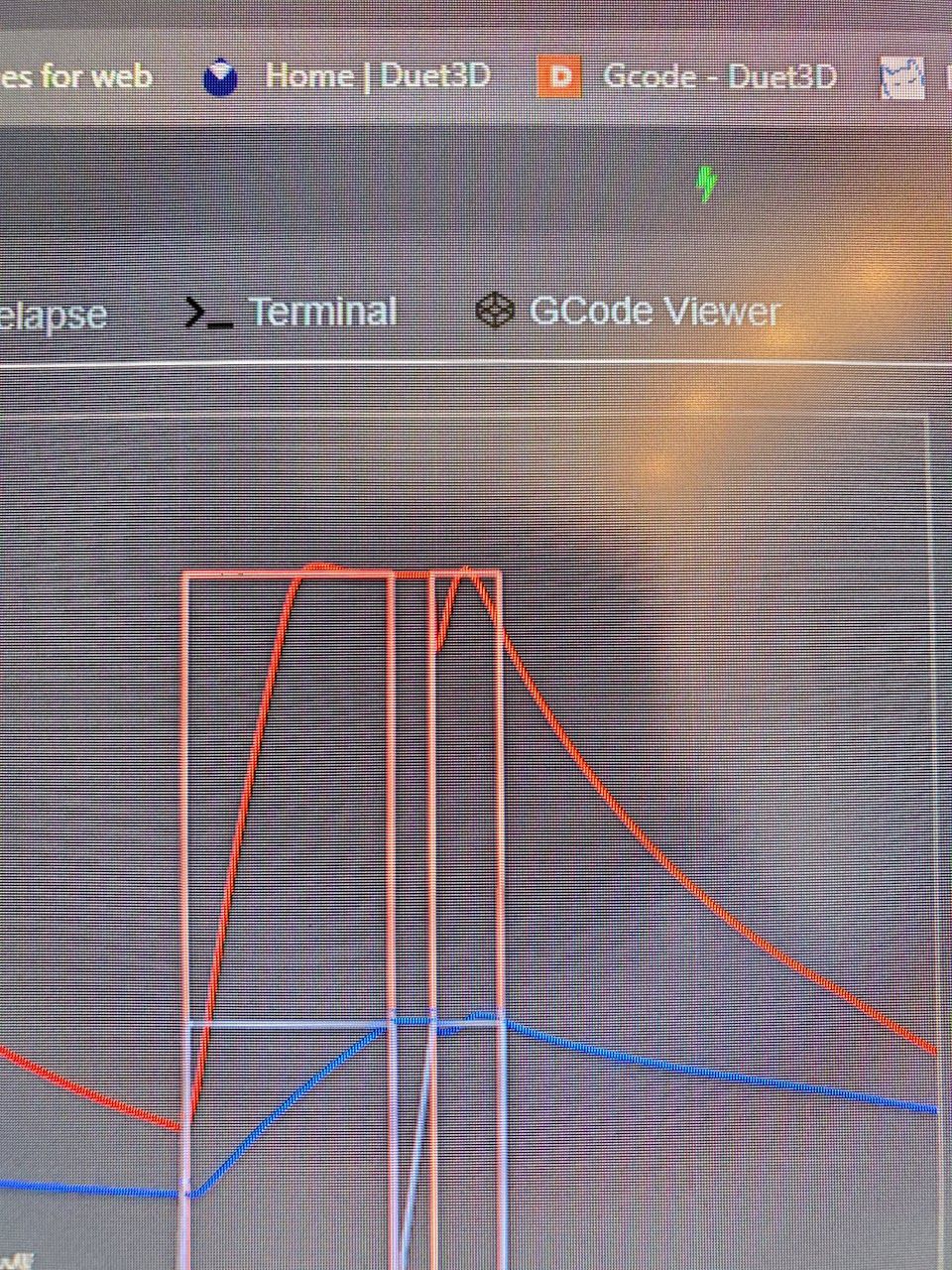

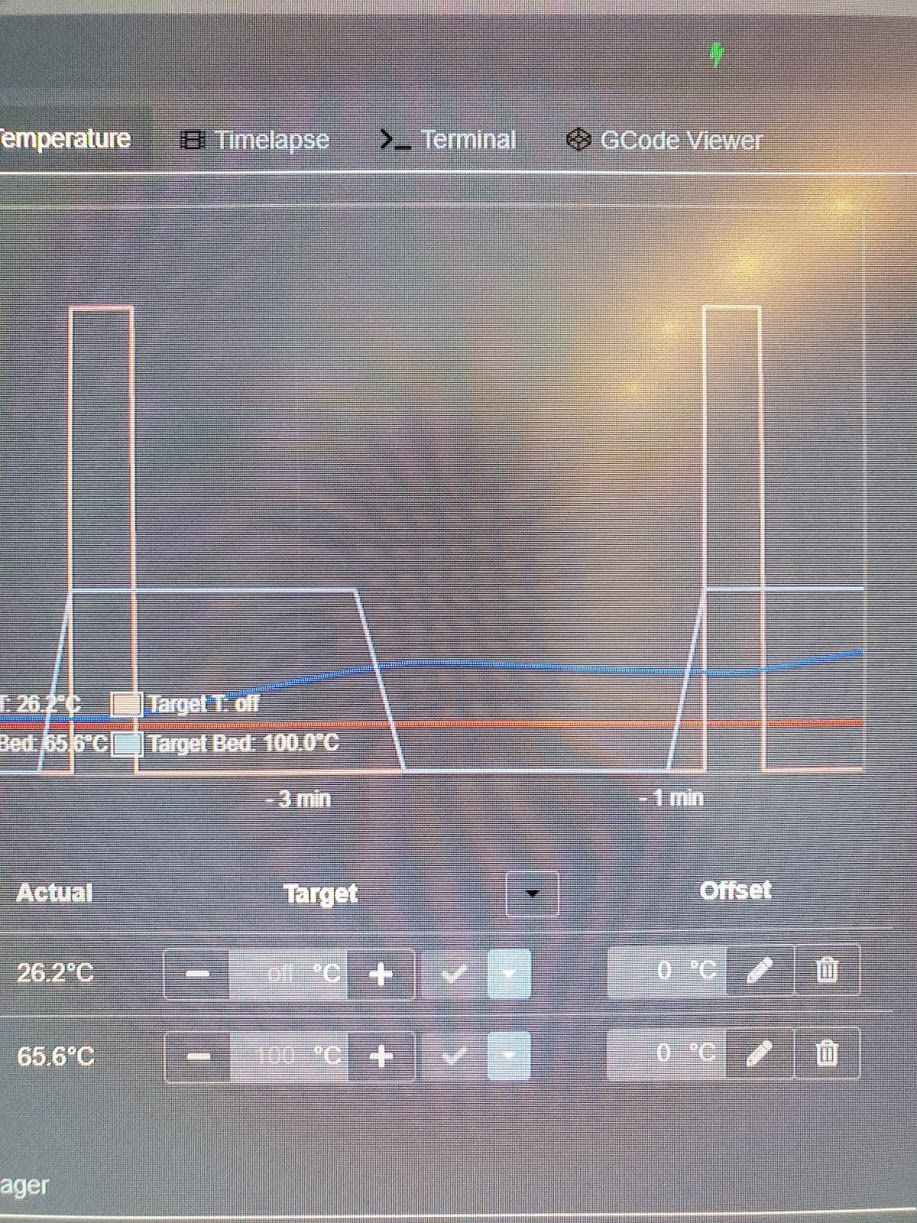

@Phaedrux The first picture, I preheated and moved the gantry around. It seemed ok. Then I turned off the heaters and started a print. The second peak in that graph is the print starting then you can see the temperature start to drop and I get the error. I reset and tried to print again in the second printer and I get "Error: Heating fault on heater 1, temperature rising much more slowly than the expected 1.4°C/sec". Reset and try again and I get the same.

Eh it looks like I'm out of commission. I got the same fault on the second heater. I'm going to go back and look at the wiring. The thermistor seems fine, it doesn't show any spikes (I had wiring go bad before and remember seeing huge jumps in its reading). So as I sit now, both heaters will give up after a few minutes. Heater 1 does not light up at all, heater 2 will light up. I swapped out the heater cart and wires yesterday. I'm going to try and swap out the thermistor to see what that does. Open to any ideas of what else to check. Good thing I got all my orders out before it died. Must have been a Christmas miracle lol.

@bearer short celebration, just died again lol. I reset and powered it up and watched the readings until it failed. 4.888 while heating, bounces around while it holds temp as it should. Then it seems to hit zero as it tries to combat overshooting, then it gets stuck at zero and I get the fault. It never gets more than half a degree high or low. I just noticed too that the heat led never comes on while it is working. What I think I will do is just use the other heater for now and cross my fingers that it keeps working until the mini 3 comes out.