RepRapFirmware 3.0 first official beta is out

-

@dc42 said in RepRapFirmware 3.0 first official beta is out:

The G92 X0 Y0 may be messing things up. Please remove it, and use M208 to set up the positions at which the homing switches trigger instead.

Didn't change anything. Z still increases. It appears that Z increases by whatever value is in the heightmap for the XY coordinates at which the XY homing was triggered. In my first example, it kept increasing by 0.173 because I was moving to the same XY coordinates before each try.

The second issue of the extra 0.700 is really baffling and it's actually causing the nozzle to crash into the bed because the Duet thinks the bed is higher than it really is.

-

Trying to set up for RRF3 here is the relevent bits from my config.g file:

; Drives

M569 P0 S1 ; Drive 0 goes forwards X

M569 P1 S1 ; Drive 1 goes forwards Y

M569 P2 S0 ; Drive 2 goes backwards Z1

M569 P3 S1 ; Drive 3 goes forwards bondtech (backwards for titan)

M569 P4 S0 ; Drive 2 goes backwards Z2

M584 X0 Y1 Z2:4 E3 ; Mapping drives X drive 0 Y1 Z2&4 E3

M671 X-50:325 Y110:110 S0.5 : Leadscrew positions for bed tramming

M350 X16 Y16 Z16 E16 I1 ; Configure micro-stepping with interpolation

M92 X100 Y100 Z1600 E144.1 ; Set steps per mm ( 99.5 for standard extruder)

M566 X2220 Y2220 Z600 E2220 ; Set maximum instantaneous speed changes (mm/min) jerk settings. was 600 600 40 Maximum jerk rates: X: 2220.0, Y: 2220.0, Z: 400.0, E: 2040.0

M203 X18000 Y18000 Z600 E3000 ; Maximum speeds (mm/min)

M201 X2000 Y2000 Z120 E1000 ; Set accelerations (mm/s^2) from X480 Y240 Z250 E1000

M204 P500 T1200 ; Lower accelerations when printing though

M906 X1600 Y1600 Z1600 E700 I30 ; Set motor currents (mA) and motor idle factor in per cent

M84 S30 ; Set idle timeout

G21 ; Work in millimeters

G90 ; Send absolute coordinates...

M83 ; ...but relative extruder moves; Axis Limits

M208 X-5:280 Y0:230 ; X carriage moves from -5 to 280, Y bed goes from 0 to 230; Endstops and set ir sensor

;M574 X1 Y2 S0 ; X home to min. Y home to max. N0pen micro-switches.

;M574 Z1 S2 ; Define Z to use Probe. Home to Min.

M574 X1 S0 P"xstop" ; X min N0pen endstop switch

M574 Y2 S0 P"ystop" ; Y max N0pen endstop switch

M574 Z1 S2 P"zstop" ; Z min active high endstop switch

M574 U1 S2 P"zstop" ; U min active high endstop switch

M558 P1 C"zprobe.in" H3 F600 T6000 X0 Y0 Z1 ;RFF3.x Set Z probe type/mode 1. Not using on XY, but using it on Z. F400 dive speed T6000 travel speed

G31 P500 X15 Y-2 Z1.46 ; Z probe trigger value, offset in relation to nozzle. And trigger height adjustment

M557 X10:260 Y5:205 S50 ; Define mesh grid at edge old M557 X0:250 Y0:210 S40; Heaters

M308 S0 P"bed_temp" Y"thermistor" T100000 B4725 C7.060000e-8 R4700 ;RFF3.x Set thermistor + ADC parameters for heater 0 BED

M308 S1 P"e0_temp" Y"pt1000" X501 R4700 ;RFF3.x Heater 1 uses a PT1000 connected to thermistor channel 1 which has a 4.7K series resistor

M950 H0 C"bed_heat" T0 ;RFF3.x heater 0 uses the bed_heat pin, sensor 0

M950 H1 C"e0_heat" T1 ;RFF3.x heater 1 uses the e0_heat pin and sensor 1

M143 H0 S120 ; Set temperature limit for heater 0 to 120C

M143 H1 S280 ; Set temperature limit for heater 1 to 280

M307 H1 A639.9 C269.5 D8.2 S1.00 V13.7 B0 ; Auto-tune copper block

M307 H0 A148.7 C890.0 D1.2 S1.00 V13.9 B0 ; AUTO-TUNE bed RESULT; Fans

M106 P0 S0 I0 F500 H-1 ; Set fan 0 value, PWM signal inversion and frequency. Thermostatic control is turned off

M106 P1 S255 I0 F500 H1 T45 ; Set fan 1 value, PWM signal inversion and frequency. Thermostatic control is turned on

M106 P2 S1 I0 F500 H1 T45 ; Set fan 2 value, PWM signal inversion and frequency. Thermostatic control is turned on; Tools

M563 P0 S"Hotend" D0 H1 ; Define tool 0

G10 P0 X0 Y0 Z0 ; Set tool 0 axis offsets

G10 P0 R0 S0 ; Set initial tool 0 active and standby temperatures to 0CI'm a bit stuck. I use drives 2 and 4 for Z and for bed leveling, do I still need to use seperate M574 commands, and can I still used bed leveling ?

-

@stewwy said in RepRapFirmware 3.0 first official beta is out:

I'm a bit stuck. I use drives 2 and 4 for Z and for bed leveling, do I still need to use seperate M574 commands, and can I still used bed leveling ?

Do you really mean bed levelling (using the Z probe, see https://duet3d.dozuki.com/Wiki/Bed_levelling_using_multiple_independent_Z_motors), or do you mean independent endstop switches on each of the Z motors? Your config.g file isn't right for either.

-

I think I solved my Z 0.700 issue. I don't know how but...

G31 Current reading 0, threshold 500, trigger height 0.70, offsets X0.0 Y0.0Nowhere in my configs to I set 0.700 for anything.

Anyway, a restart seems to have solved that issue.

I'm retesting mesh probing and the heightmap thing now. -

@dc42 bed leveling using the bed leveling probe (an ir sensor, one of yours

)

) -

Yeah I still have the issue with the Z height changing when homing XY when a heightmap is in effect.

-

@gtj0 said in RepRapFirmware 3.0 first official beta is out:

Yeah I still have the issue with the Z height changing when homing XY when a heightmap is in effect.

On my list to investigate, but may have to wait until after TCT.

-

@dc42 said in RepRapFirmware 3.0 first official beta is out:

@gtj0 said in RepRapFirmware 3.0 first official beta is out:

Yeah I still have the issue with the Z height changing when homing XY when a heightmap is in effect.

On my list to investigate, but may have to wait until after TCT.

No problem. I'll nose around a bit this weekend.

-

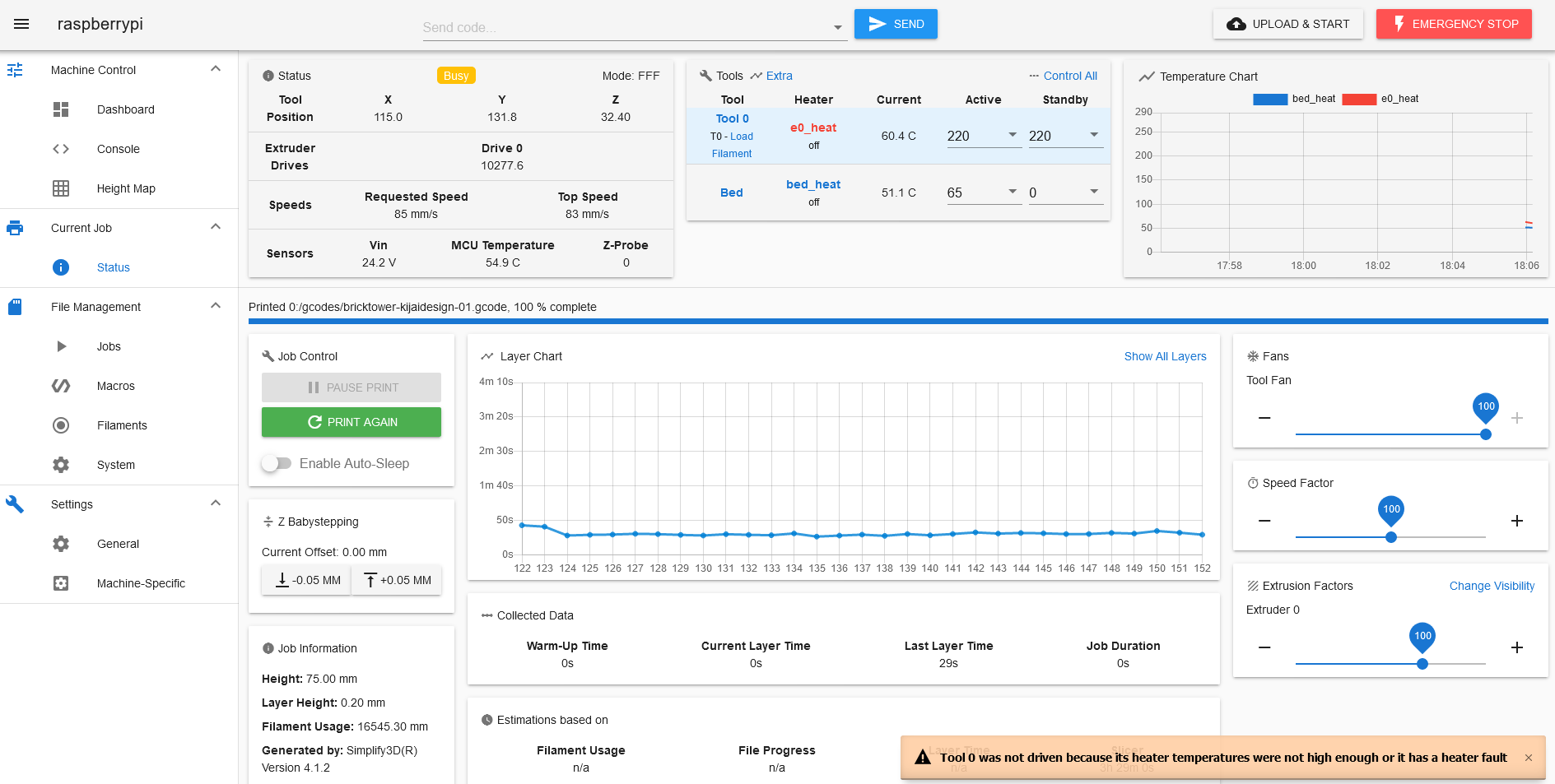

Odd one. Heater faulted halfway through a print. Print kept going, but shows 100% for a status (can't cancel it anymore). Obviously not extruding, just still moving. DWC went unresponsive on me, too. Really odd.

No idea why the heater faulted yet.

-

@kraegar This means this issue has not been fixed, yet.

EDIT: which version of DSF are you using? That might make my above assumption incorrect.

-

With this build I encounter problems with heater mapping. The values found are -273 with the exception of the heated chamber which is correct.

; 9 _ HEATERS

M308 S0 P"bed_temp" Y"thermistor" A"Bed thermistor" T100000 B3950

M308 S1 P"spi.cs1" Y"rtd-max31865" P"spi.cs1" A"RTD1"

M308 S2 P"spi.cs2" Y"rtd-max31865" A"RTD2"

M308 S3 P"e2_temp" Y"thermistor" A"Chamber thermistor" T100000 B4725 C7.06e-8M950 H0 C"bed_heat" T0

M950 H1 C"e0_heat" T1

M950 H2 C"e1_heat" T2

M950 H3 C"duex.e2heat" T3 -

@Marco-Bona said in RepRapFirmware 3.0 first official beta is out:

M308 S1 P"spi.cs1" Y"rtd-max31865"

P"spi.cs1"A"RTD1"are you definitely using .cs1 and .cs2 not .cs0 and .cs1 (i.e you have one daughter board) also remove the second P value

-

@kraegar I recommend using DSF 1.0.3.3

-

@t3p3tony

Sorry but the second P value was a bonding problem.

For DSF I realized that it was only for Duet3, I'm using Duet2. If it is to be installed where can I find the file? -

@Marco-Bona No you are right DSF is only Duet 3

-

@T3P3Tony Thanks - I wasn't pointing to the unstable repo. Also, easy fix, but might trip up someone not linux savvy, you're missing a sudo on the apt-get install line of the instructions.

-

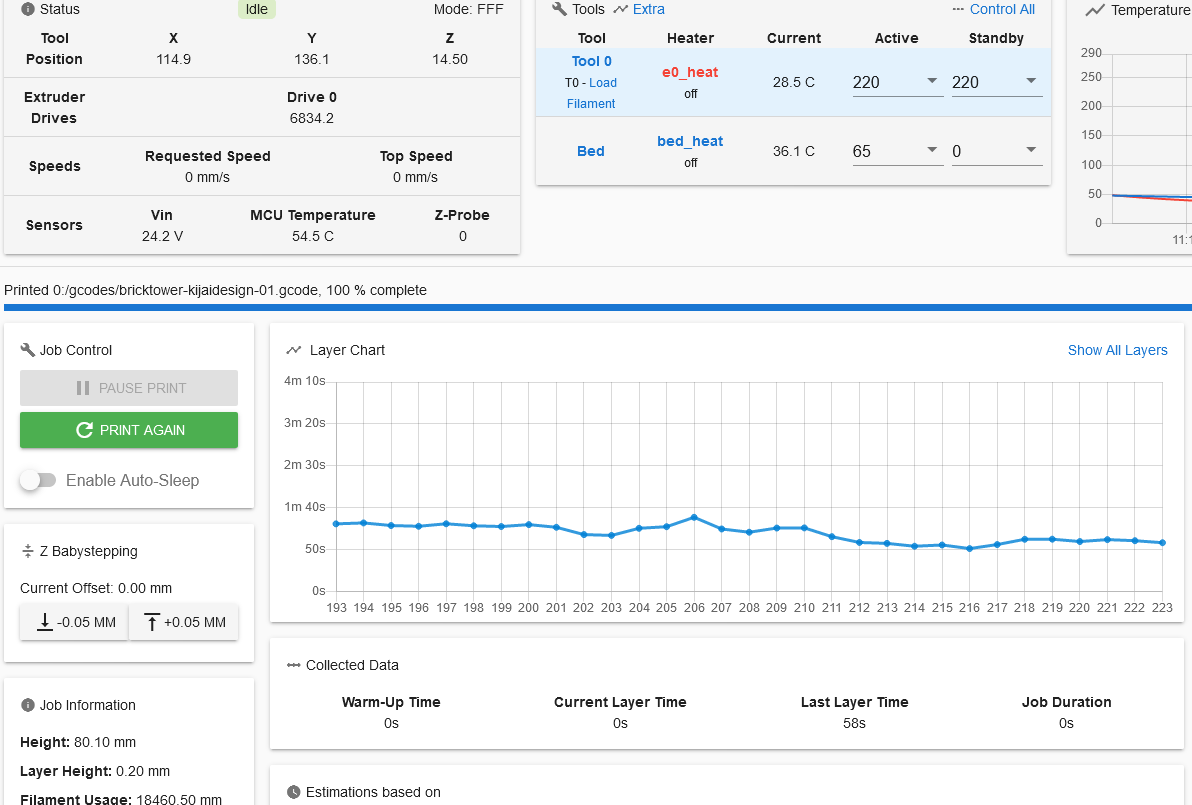

Failed again, at 14.50mm of an 80mm print. Reports it's 100% but definitely is not.

-

I'd only used systemctl to restart all the duet processes. Trying a print from a known reliable slice from my duet2, with a fresh boot on the latest software on the unstable branch.

-

-

@T3P3Tony said in RepRapFirmware 3.0 first official beta is out:

apt list 2>/dev/null | grep duet | awk -F'[/ ]' '{print $1" "$3 }'

FIRMWARE_NAME: RepRapFirmware for Duet 3 v0.5 FIRMWARE_VERSION: 3.0beta10 ELECTRONICS: Duet 3 prototype v0.5 FIRMWARE_DATE: 2019-09-12b1

duetcontrolserver 1.0.3.3

duetruntime 1.0.3.3

duetsd 1.0.2

duetsoftwareframework 1.0.3.3

duettools 1.0.3.3

duetwebcontrol 2.0.0-4

duetwebserver 1.1.0.0