CR-10S5 Firmware

-

Your thermistor settings are wrong for both your bed and hotend.....The bed should be M305 P0 T100000 B3950 R4700 and the volcano if it has the E3D cartridge thermistor should be M305 P1 T100000 B4725 C7.060000e-8 R4700

-

Thanks, I changed that before this print: ![alt text]

-

I've got a lot of tweaking to do.

-

It's not... THAT bad... I guess.

-

The e3D volcano keeps getting clogged. In between the nozzle and the Capricorn tube there is a little gap that wont close and the filament expands into that and wont let me extrude. I purchased the bontech extruder to hopefully overpower the clog. Any thoughts on what to do?

-

When holding the bowden tube firmly in place, fit the little clip. This should prevent the bowden tube from moving and the gap opening.

If you don't have a clip, fit a tie wrap to keep the bowden fitting in the heat sink in its highest position. -

I have a clip, however this dose not work. Confusion?????

-

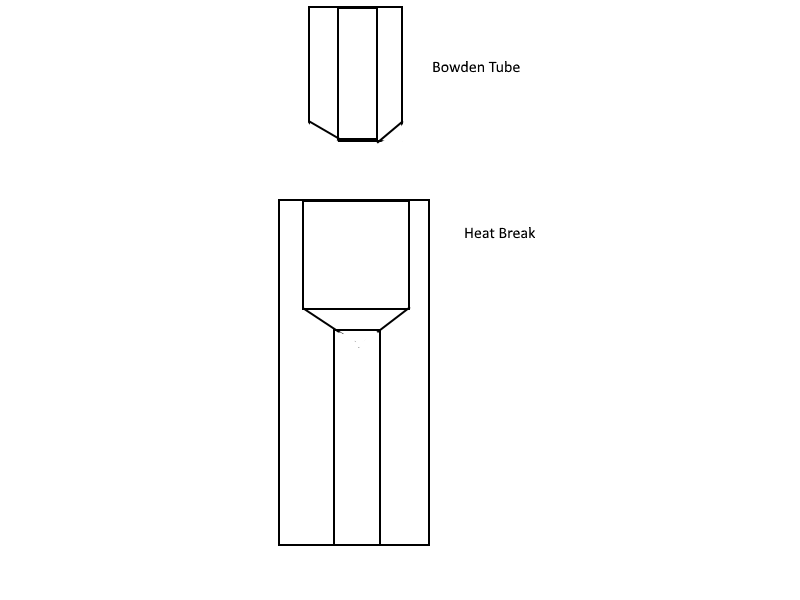

I had an instance where the bowden tube wasn't seating correctly in my volcano. I ended up shaving the end of the tube to give it the same angle as the bottom of the hole in the heat break so it sat further down.

-

I was think of doing that, but have been to lazy to do anything today. Latterly been sleeping all day and playing CIV VI. I did add the bondtech extruder today, so I wasn't as lay as I wanted. I had to take the X-Axis arm off just to switch one bolt around, took about 4 hours of laziness away

. I will post pictures and the new config code for the bondtech hopefully tomorrow. Then I will start the second print. May the odds ever be in my favor.

. I will post pictures and the new config code for the bondtech hopefully tomorrow. Then I will start the second print. May the odds ever be in my favor. -

I will post the code later, I just purchased a new z nut as the one on the right is very hard to use. (All the weight is on the right). The right Z-Axis motor is tough to turn now, lol.

-

@Gost101 I'm done trying to use the volcano, I'm going to try to return it. It always clogs, I've tried tapering the Capricorn tube, it always clogs even mid print if I can get it started. I've tried putting a bontech extruder on this. I'm very frustrated and pissed off.

-

Lol, it prints slow. I cannot increase the speed. Can anyone help?

-

Just as an additional data point: I also use a Volcano system and I have no problems now. It was frustrating to set up initially but it's working nicely now. Too much retraction was an issue with me but the one thing that stumped me for the longest time was the fact that I had the heatbreak too far out of the heatsink (Chimera setup). The necked down section of the heatbreak must be located within about 2 mm of the heatsink bottom otherwise the heat travels up too far in the heatbreak and can cause clogs where the capricorn tube meets the heat break.

The Chimera setup has no threads on the heatbreak section that goes into the heatsink and with the heater and thermistor in the cramped space above the heat block, I just ended up having everything just a tad too far out of the heatsink. It was a real pain to figure this out because sometimes everything worked, sometimes it would clog on retraction, sometimes it would clog when the filament was pushed through too slow - it was a nightmare.

Heat paste on the heatbreak section that is in the heatsink is also highly advisable. -

In addition, I did a test print once going back to the original hotend. It was very slow and would stop after every move and leave a little blob. I cannot speed it up through the g.code files, or the web interface. I will post a video shortly of what is happening.

-

Here is the video link: Print Video

-

Can you post your current config.g and a sample sliced gcode file?

-

Hey @Gost101, I can't think of anything that would clog a volcano, but here are the things that I'd check (in case you haven't already)

-

kinked tube, obstruction in filament path

-

vastly oversized filament

-

burr or debris in the nozzle

-

insufficient stepper current or other mechanical cold end issue

I was seeing an irregular print surface on one side, I pulled the nozzle off, used a propane torch to clean it out, and a 5/64" drill bit by hand to check the barrel for burrs and other obstructions.

-

-

I have already switched over to the included nozzle and have had much better prints, and it doesn't clog. But it has a lot of stringing and prints very slow. Regardless of retraction distance and speed, plus z hop, I cannot stop stringing. It takes a normal bench on from cura at 15% infill with triangles internal support. I'm negating to mention the height and width, plus a couple of other factors because I forget what they were and my laptop is being repaired by razer. A couple of hours long print takes 12 hours to actually print.

-

Looking at your config from your post, some of your values are rather low... This is what I have on my Ender 3 which should be similar for you. I think you need to up your speed, accel and jerk(instantaneous speed) on your extruder.

M350 X16 Y16 Z16 E16 I1 ; Configure microstepping with interpolation

M92 X80.00 Y80.00 Z400.00 E408.30 ; Set steps per mm

M566 X500.00 Y500.00 Z30.00 E1500.00 ; Set maximum instantaneous speed changes (mm/min)

M203 X10800.00 Y9000.00 Z300.00 E3000.00 ; Set maximum speeds (mm/min)

M201 X1000.00 Y1000.00 Z500.00 E3000.00 ; Set accelerations (mm/s^2)

M906 X950.00 Y950.00 Z850.00 E900.00 I30 ; Set motor currents (mA) and motor idle factor in per cent

M84 S30 ; Set idle timeout -

@JamesM said in CR-10S5 Firmware: It still prints very slow.

In addition the nozzle will not retract in the helps of stopping blobs.