I want to build in" Duet 2D Wifi " into a Anycubic Predator.

-

Thank you I think that will help,

Pegaso

-

The Haydn rods are 80mm shorter than the rods that came on the predator (440mm -> 360mm).

What is your new build volume with the shorter arms?

Did you have any other issues using shorter arms?

Can the smart end effector be attached to the rods that came with the anycubic predator?

I'm considering making the same upgrades to my predator (bondtech extruder, duet3d, and smart effector) but I'm unsure about changing out the arms. I've been working with 3d printers for several years now, but this is my first delta.

What is the benefit in magnetic arms vs the ball-joint rod end type arms?

-

@oryhara said in I want to build in" Duet 2D Wifi " into a Anycubic Predator.:

The Haydn rods are 80mm shorter than the rods that came on the predator (440mm -> 360mm).

What is your new build volume with the shorter arms?

Did you have any other issues using shorter arms?

Can the smart end effector be attached to the rods that came with the anycubic predator?

I'm considering making the same upgrades to my predator (bondtech extruder, duet3d, and smart effector) but I'm unsure about changing out the arms. I've been working with 3d printers for several years now, but this is my first delta.

What is the benefit in magnetic arms vs the ball-joint rod end type arms?

Hayden makes different length arms it is just that Duet AFAIK only stock the 360mm ones I for example have 450mm ones on my home-brew delta

-

Here take a look here..... you can also get his files... it works

[https://www.jayuk.org/anycubic-d-predator-upgrade-to-duet-part-1/] -

Thank you. Now i feel silly for asking. I also found haydn's website. The link on duet3d is broken, still going to google+, btw.

So new question: do you still use the predator carriages?

Also having read your blog: Why is it bad to tin the end of bare wires with solder?

-

Solder on the end of the bare wires is just bad practice.

Eventually the screw terminals could come loose etc.You can use a smart effector with the original arms, just be warned that the fisheyes on the rods are of poor quality and tend to wear fairly quickly.

If you're changing the arms, you still keep the original carriages (the bits with the rollers), it just depends on whether you're fitting a smart effector on which adaptors you use.

The smart effector has 55mm between ball centres and the original effector is 64mm. You need to make sure you keep the arms parallel at all times.If you're changing the arms and fitting a smart effector, use the PCB's supplied with the effector and use these adaptors

-

Thank you sir. I hadn't considered the wires coming loose in the terminals. I remember horror stories of untinned stranded wire coming loose to the point of only 1 strand conducting, which causes it to catch fire. So I always tinned my ends.

But I guess ferrules is the best option. I'll have to start doing that.Thank you for the guidance regarding the carriage adapter.

I wish i hadn't sent a long question to haydn about how to mount the ball ends on an anycubic predator, since the existing mounting holes are sideways...

-

Is there any significant downside to using the duet maestro with the predator, vs the standard Duet?

I'd go ethernet either way.

-

Not that I'm aware of.

Its up to you. -

ok then.

Thank you for your help.

-

@oryhara said in I want to build in" Duet 2D Wifi " into a Anycubic Predator.:

Why is it bad to tin the end of bare wires with solder?

Solder under a screw terminal "creeps". Which makes the connector loose. Which increases resistance. Which causes heat. Which causes it to creep faster. Eventual result is a very high resistance connection and (if enough current, like on a bed heater connection) lots of heat inside that screw terminal.

Lucky? Burned terminal/connector. Unlucky? Burned house.

For screw terminals, ALWAYS either bare wire (twisted) or "bootlace" terminals that crimp onto the wire. Never solder associated with the pressure part of something that is 'clamped' by a screw or any other form of mechanical pressure.

-

I managed to get my predator upgraded with a Duet Maestro, smart effector, and Bondtech BMG extruder, just like in your post, Jay.

Your config.g worked except for the bed thermistor has a different R -value for the maestro than the regular duet board.

I have one question: what kind of bowden tubing are you using? did you keep the PTFE that came with the predator, or did you swap in some capricorn tubing?

My printer is stripping the ptfe out of the bowden couplings, which is why i ask. Going to clean out the hotend tonight in case that's the cause.

-

@oryhara I've had the same issue as well, whether I've been using cheap PTFE or Capricorn tubing. I ended up changing the pneumatic fitting on the BMG clone and I've since had no issues

touch wood, fingers crossed.

My PTFE tubing is significantly shorter than the original at roughly 200mm. -

WHat did you change the extruder fitting to?

also what is "touch wood"

I only had one grommet clip so i switched from the e3d groovemount bowden fitting to the bigger fitting that was on the extruder that came with the predator. It's grommet maintained tension without a clip so I thought that would help.I am concerned that the 'flying extruder' mount is letting the extruder wobble around too much and that swinging is being constrained rigidly(distance-wise) only by the PTFE tubing. THe springs constrain it flexibly. so it bounces all over the place against the PTFE tubing and that just rips it out.

So 200mm only tube. That seems like it is at least as long as the original. I wonder if a direct mount would fix the problem. Or perhaps if I anchored the wire harness to the extruder to limit its motion and constrain it by one more point. again, rigid with respect to distance.

-

Touch Wood is a local statement meaning "may my good luck continue". Also sometimes called "knock wood".

-

Thinking on it, it may only be around 150mm of PTFE i've used.

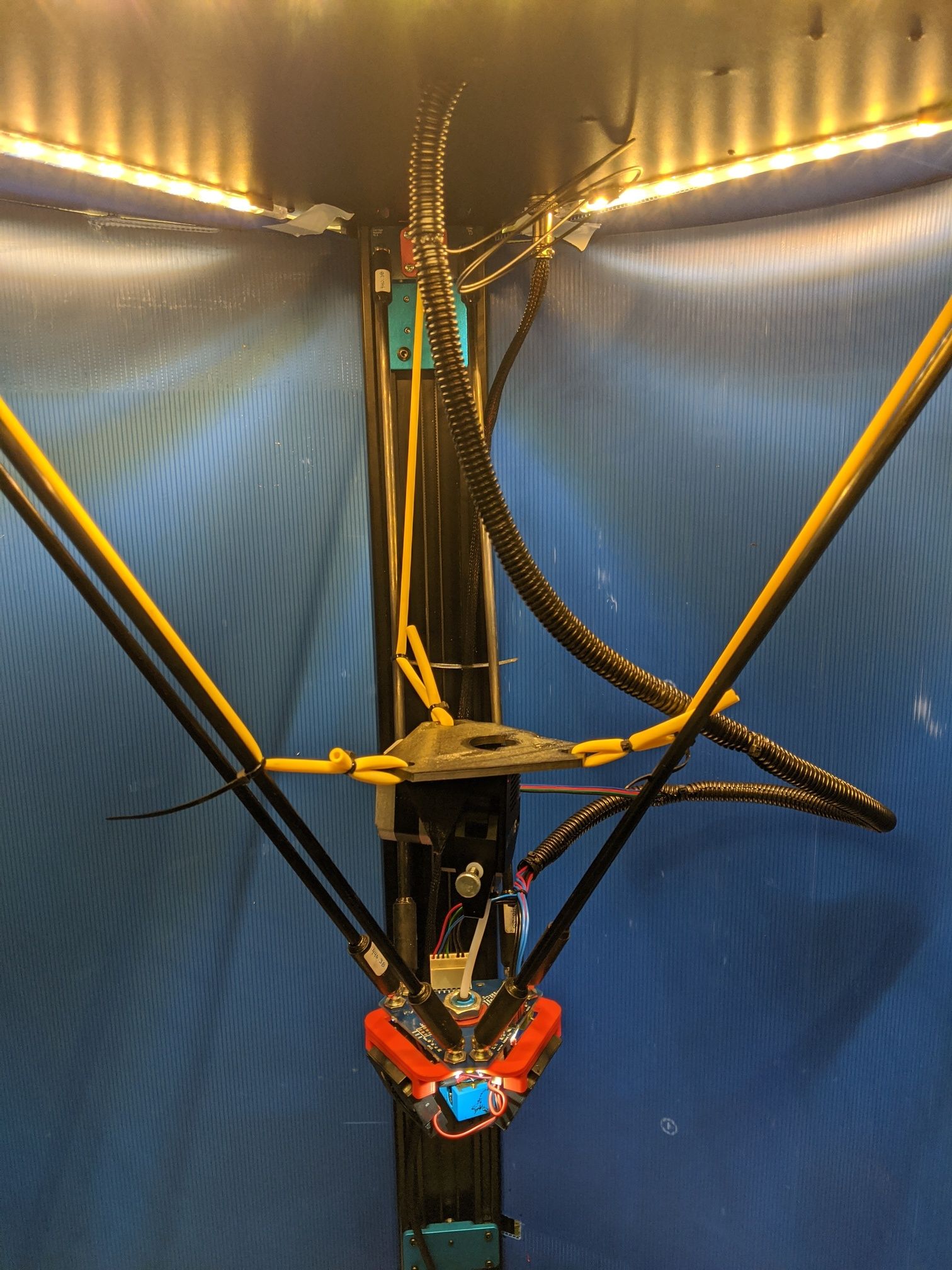

I tapped the hole in the extruder 1/4" BSP and fitted a fitting I had on hand.I've changed my flying extruder from using springs to using rubber tubing.

I've also constrained the extruder from wobbling around by cable tieing the rubber to the arms as low down as I can.

I'll upload a picture when I get home later -

@oryhara said in I want to build in" Duet 2D Wifi " into a Anycubic Predator.:

My printer is stripping the ptfe out of the bowden couplings, which is why i ask. Going to clean out the hotend tonight in case that's the cause.

Do you mean that the extrusion force is pushing the PTFE tube out of the couplings? If so, that could mean that you are printing at too low a temperature, which could mean that your thermistor settings are incorrect in the M305 commands in config.g.

-

@dc42 I had mine pull out when I was using a PT100 and when using the stock e3d thermistor (with the correct config settings).

Some of the couplers used are just rubbish. -

I'm pretty sure the thermistor settings are correct. they are the settings for an e3d thermistor, which is what I'm using. They read about the same as the bed when cold(room temperature), but I don't have the means to really test them better than that.

Or i don't know means to do so. I guess I could take another printer's temp probe and hold it against the heat block but that sounds like a dumb idea. and potential to break both printers and burn my hands.Yes it strips the PTFE tube out of the coupling. Usually at the extruder end. My other bondtech extruders did this when I first switched to Volcano. Even at ludicrously high temps(300 for ABS) it just couldn't melt enough plastic to extrude at that speed. So its not just temp, it's speed. Or perhaps more accurate to say its volumetric extrusion melt rate that is the limit.

Except i'm printing at the same speed as before with the knockoff e3d head that came with the anycubic printer. And the same nozzle diameter(.4mm) but this time with a bondtech extruder.

The no-name extruder it came with would strip the filament instead of the PTFE tube, which is almost a downside to bondtech. Teeth on both sides won't strip the filament, but it will pop the bowden tube out and then feed a bunch of filament through. If the filament just gets a bite out of it, you lose the print, but the filament not fed is still good. I couldn't re-roll the filament it fed after popping the PTFE tube, and it was several meters went to waste. granted that's like $2 or something, but still kinda annoying.

I probably need to clean the nozzle. I probably had a gap at the bottom of the tube inside the heat break from the grommet moving down on insertion, then back up to apply the grommet clip. I should hold it up while inserting the tube to make sure there is no play before getting the clip on there.

Are the threaded ptfe couplings better than the groovemount-type couplings?

-

I promised an image of my setup so there you go.