Motor noise and print quality

-

otherwise i wish you luck

-

@grizewald said in Motor noise and print quality:

@sethipus Thanks, I might be needing that luck!

I feel there is going to be some Dremel assisted violence visited upon the pulley today. I can't see any way to defend the stepper's bearings against the use of a hammer to slot the set screw, so cutting a slot through the pulley and into the set screw with a cutting disc would appear to be my only option. If slotting it fails, I'll just cut straight down along the flat part of the stepper's spindle and hope the cut misses the broken ball end. I don't much rate a cutting disc's chances against tool steel, even if it's cheap and nasty tool steel.

I rate the chances pretty highly actually. If you're going slow even if you hit the ball head your cutting disc should go through it just fine.

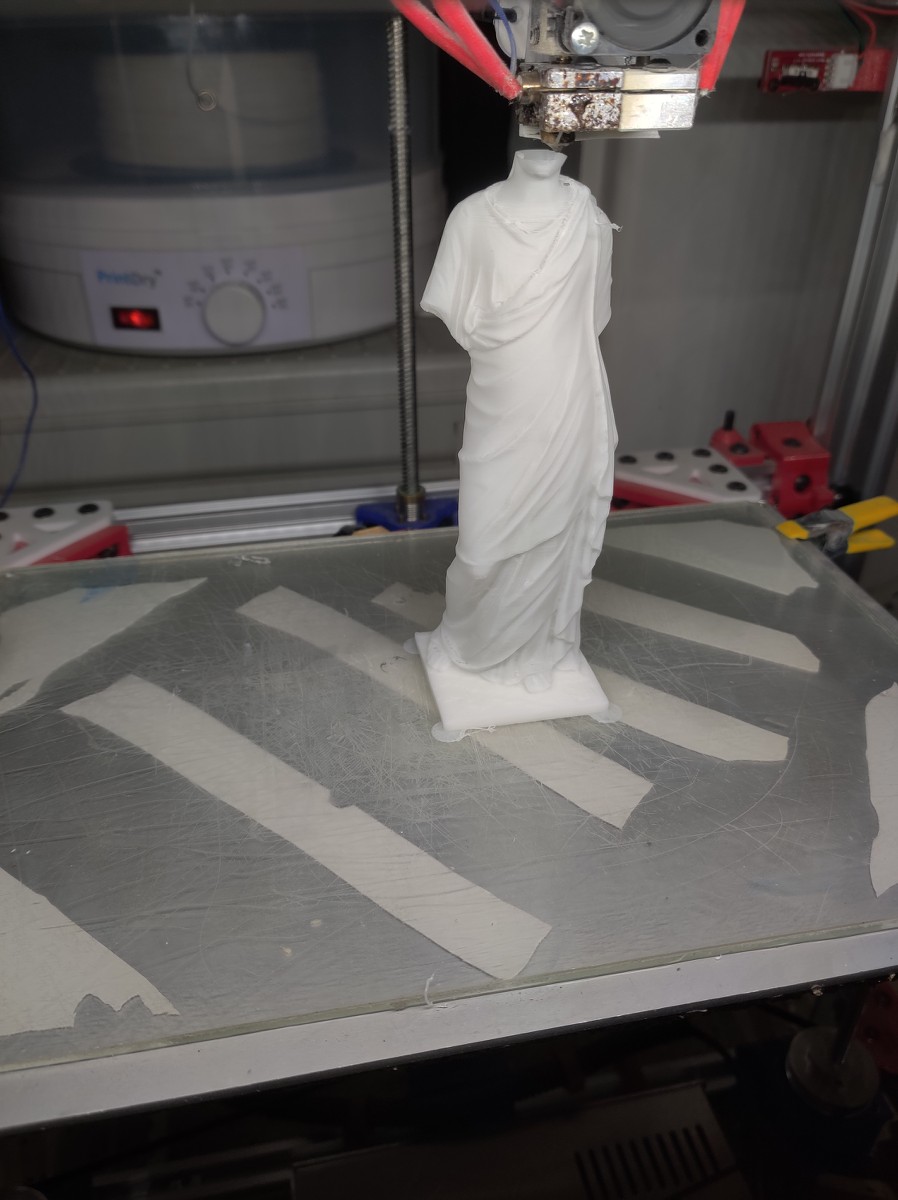

I printed a tall sculpture over the last couple of days and noticed a mechanical problem which I need to look at. When the printer was performing a 100mm/s travel move in the +X direction, the print head would clip the support layer it was travelling over with a loud 'snap'. If it wasn't for the fact I'd anchored the sculpture with a brim, I'm pretty sure the collisions would have knocked the print over. Even though that didn't happen, the resulting wobble lead to increasingly poor finish as the print got taller.

I've had that happen before. It's not always mechanical. It's possible the support structure is just curling up a little. Had that sort of thing happen many times. In fact, between reading your post and replying to it I heard a noise I didn't like the sound of. I'm printing a Greek statue in vase mode, and in a particularly tight fold of the woman's robe the head was making a very sharp turn, and apparently part of a line curled up just enough that it was starting to hit and get worse with each go around. I had to pause it twice and, with a little knife, cut a shaving of plastic off that was sticking up. As the fold continued up the statue it was happening again after a couple go arounds, and I ended up just very gently putting my fingers around the statue and holding it just enough to resist the gentle bump by the nozzle, and after several go arounds it got past that point and the problem was averted. I'll probably have some tiny little quality hiccup at that spot if I look at it carefully, but I did save the print. (so far, it's not finished yet, and I worry about the top of the head)

I found the Bondtech BMG remarkably immune to non-linear extrusion effects when I tested it. It was only when I got to 5mm/s extrusion that the amount of filament extruded would start to differ from what was commanded, so I've left that uncorrected for the moment.

I admit I set my non-linear extrusion parameters using my previous extruder, which was a belted, single-drive extruder. The values obtained were very small, and I haven't changed them, and they don't seem to be hurting me. I think I'll go through the tests again this weekend with the BMG clone and see how much different results I get. I don't think they'll change much until I get up to 6mm/s or so, because I believe a lot of the reduction I was seeing in feedrate at higher speeds was due to backpressure in the melt chamber, which hasn't changed, and didn't slip until the 5-6mm/s range.

-

Victory!

I saw the tiniest of sparks as the disc cut into the remains of the ball end. Looking at the cut, I reckon my ball end driver was no harder than the set screw.

So, time to get the original pulleys on and do some testing.

-

Interesting. Changing to 0.9 degree steppers had a significant effect on how noisy the printer is. Old and new figures:

Print speed Noise (dbA) - 1.8 degree steppers

60mm/s 51.5

90mm/s 55.3

120mm/s 52.5With 0.9 degree steppers

60mm/s 54.0

90mm/s 53.4

120mm/s 56.1It'll be interesting to see what the print looks like when it's finished.

-

Well, I can't say that the 0.9 degree motors made any particular difference, apart from making the printer nearly twice as loud at 60mm/s and over twice as loud at 120mm/s!

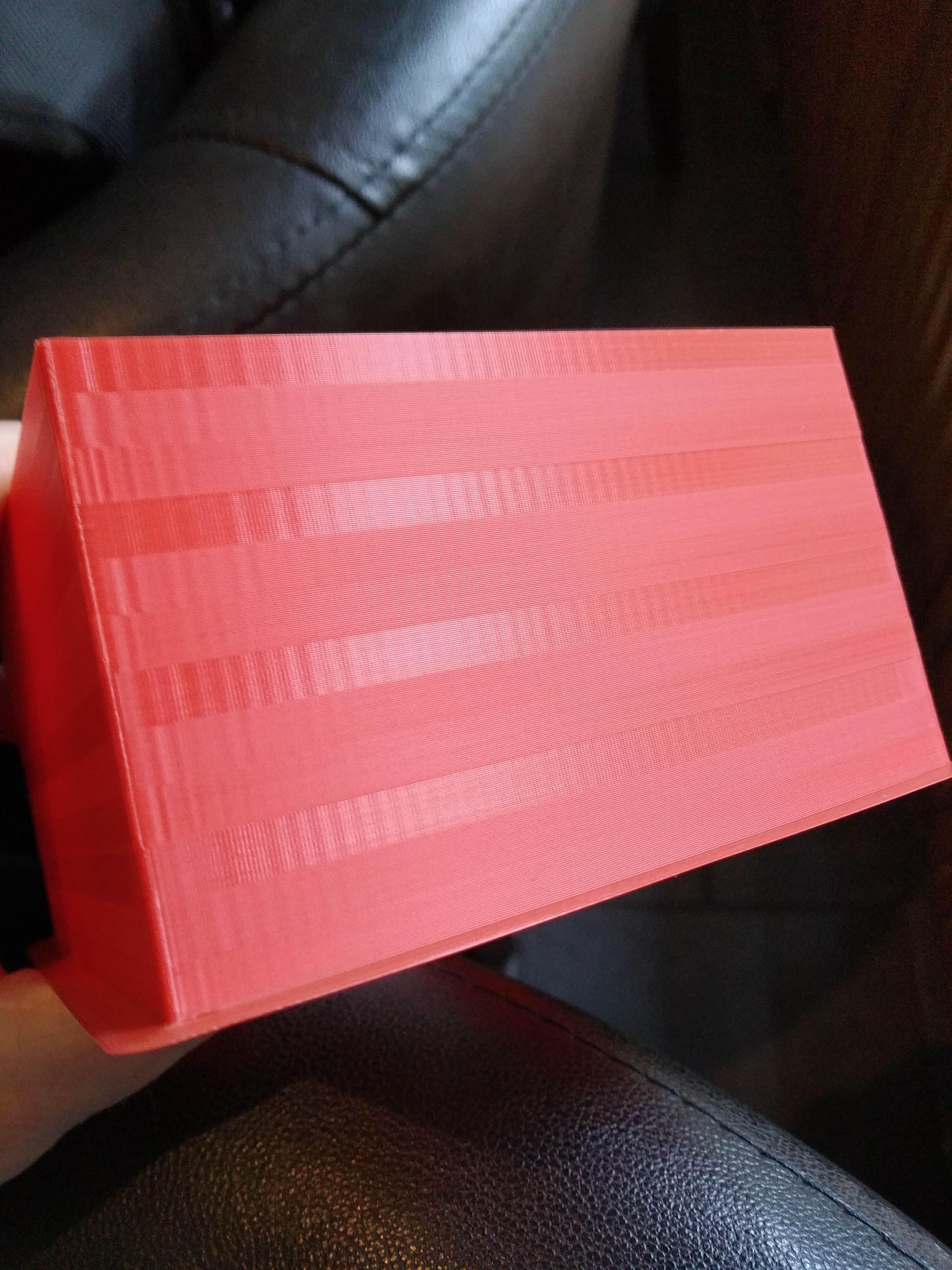

The 120mm/s layer is still the smoothest, unwanted vertical artefacts are still present at around the same frequencies and ringing is distinct and worsens with acceleration.

These various artefacts are pretty annoying on some prints, so I guess I'll have to carry on with the various tweaks to be found here on the forum and see if I can improve things.

-

It looks like you're getting a much finer and more closely spaced vertical artifact, and then a much wider spaced and broader artifact, that looks very much like the "corduroy effect" I talked about with my prints, that has an ~2mm wavelength and thus is almost certainly connected with the gt2 belts. I don't recall what printer you're using @grizewald, but is it using gt2 belts to drive the X/Y access? And if so, are there places where your toothed belts are running around idler pulleys, whether smooth or toothed?

I've just reprinted the corner braces for my (massively customized) D-Bot, and I'm going to install the smooth pulleys in those braces, and tonight rebuild the top end of the printer with the smooth pulleys, and install new belts with a twist in them so that toothed belt is never wrapping around smooth idlers (ie: the flat back side of the belts will wrap around the idlers). Phaedrux reported that he'd been seeing the same corduroy effect as I do, and that when he stopped toothed belt from wrapping around his idlers on the 2mm-pitch toothed side this corduroy effect went away. I should be in a position to confirm or deny that with my printer something either tonight or at least sometime this weekend.

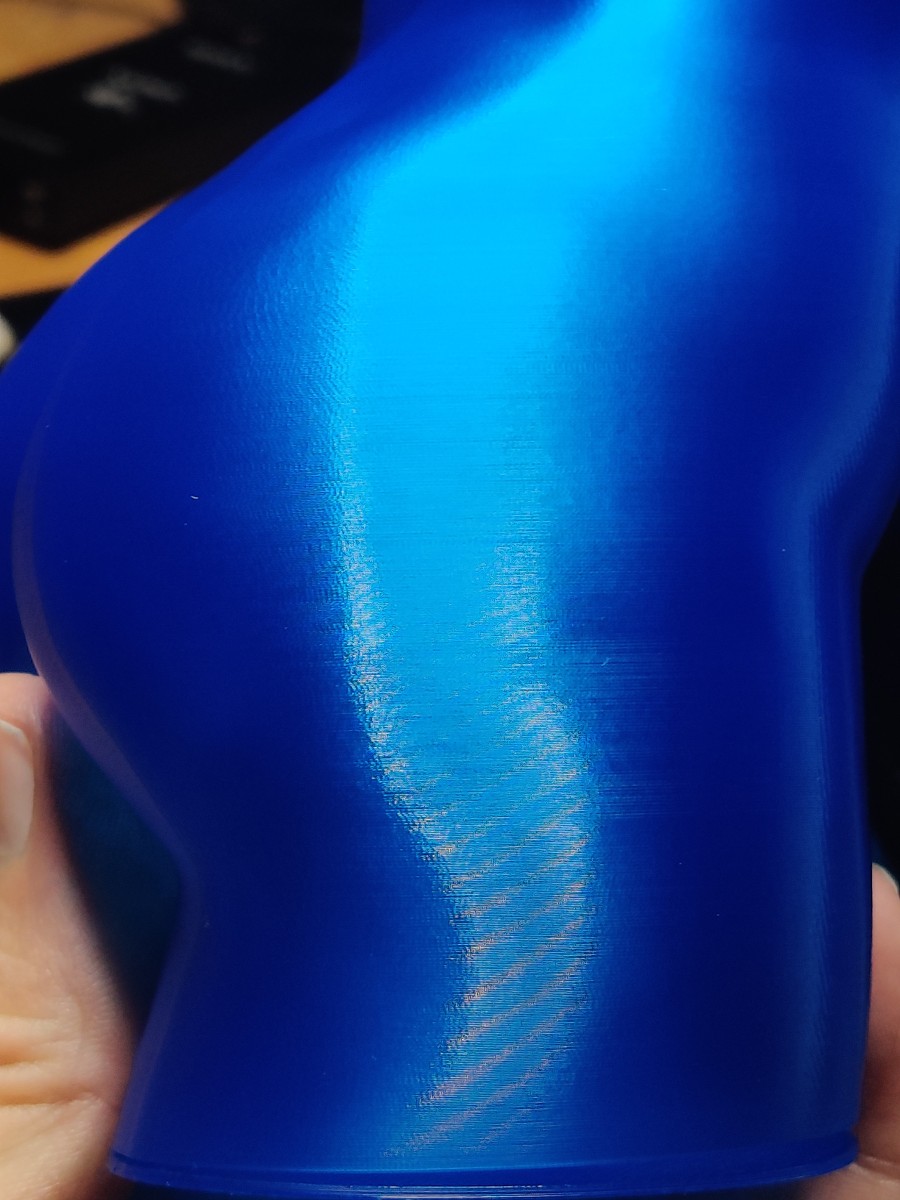

That corduroy effect obviously is all lined up like in your photo on flat surfaces like boxes and whatnot, but on curved surfaces it still shows up in very distracting patterns, as in this little snippet from another vase-mode print. It's this I'm hoping goes away after my work on the belts and pulleys this weekend.

-

@sethipus said in Motor noise and print quality:

I don't recall what printer you're using @grizewald, but is it using gt2 belts to drive the X/Y access? And if so, are there places where your toothed belts are running around idler pulleys, whether smooth or toothed?

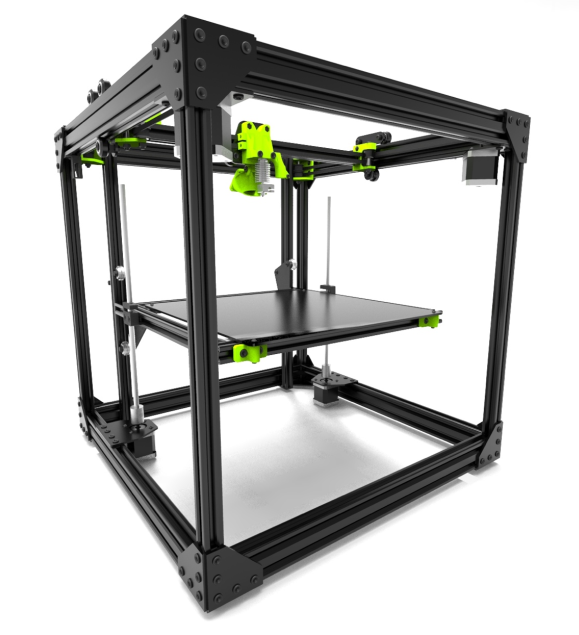

My printer is the V-Core from RatRig. They've just released version 2, so the pictures for version 1 are no longer present on the site, but it's big Core-XY based on OpenBuilds parts with a nominal 300 x 300 x 300mm build volume.

It looks like this:

It does use GT2 belts and apart from the pulleys, the belts go around OpenBuilds smooth idlers. It would be very difficult to arrange twists in the belts so that every idler had a smooth belt side running around it.

-

@grizewald said in Motor noise and print quality:

@sethipus said in Motor noise and print quality:

I don't recall what printer you're using @grizewald, but is it using gt2 belts to drive the X/Y access? And if so, are there places where your toothed belts are running around idler pulleys, whether smooth or toothed?

My printer is the V-Core from RatRig. They've just released version 2, so the pictures for version 1 are no longer present on the site, but it's big Core-XY based on OpenBuilds parts with a nominal 300 x 300 x 300mm build volume.

It looks like this:

It does use GT2 belts and apart from the pulleys, the belts go around OpenBuilds smooth idlers. It would be very difficult to arrange twists in the belts so that every idler had a smooth belt side running around it.

I had a close look at my D-Bot's setup and a single twist (per belt) immediately after the stepper itself, on the outer belt run (ie: not the one that must remain parallel) will ensure that the back side of my belt runs against the idlers for the rest of the run. When I first tried addressing the corduroy effect, I swapped out the smooth idlers for toothed ones, but it didn't really help. There is this microscopic jump in the X and Y motion as each tooth engages (or each ridge on the belt hits a smooth idler) that results in very slight extrusion rate differences on a printed straight line, and that's what's causing this effect.

Anyhow, CoreXY is CoreXY and I'd be surprised if your printer's belt runs are really any different than mine in this regard. Is there really no way to introduce a twist in the outer belt run away from each stepper, to get smooth belt backside against the idlers?

ETA: I really wish I'd built my D-Bot to the 300x300x300 version. I built mine to the 200x300x300 version. In theory it wouldn't be too hard to change mine, just four lengths of v-slot rail and a new build platform, but I just can't bring myself to do it. What concerns me more than that extra 100mm of Y axis is getting my printer enclosed. I've tried printing PC and nylon and ASA and whatnot without an enclosure without a lot of success (well, had more success with the nylon than the other two). My biggest thing is that I've got things that would be inside the enclosure if I just put a large box over it that I don't really want heated, like the power supply, Duet Wifi controller, and steppers, plus the bowden tube is sticking up from the extruder, which is mounted to the top rear frame rail. One of my next big upgrade projects will be to move everything that might be heat sensitive out of the build volume area, and figure out some attachment points or whatever for some materials that can enclose the build volume itself.

-

@grizewald said in Motor noise and print quality:

It does use GT2 belts and apart from the pulleys, the belts go around OpenBuilds smooth idlers.

that is certainly something that could cause the 2mm issues on your prints.

-

I looked at the belts again and you're right - if I put a twist in the J and K lengths, my belts will indeed travel with the smooth sides against the smooth idlers all the way around.

I just have to modify a part and print it as the upper belt holder won't work with the belt the other way around. So that's next in my print queue!

-

@sethipus The DBot isn't a very good candidate for enclosure. It's way more work than it's worth IMO. I've made do with a plastic shroud that can hang around the entire printer on it's stand. It's like a loose curtain. At the top is an exhaust duct. It works fairly well with ASA, etc, both with chamber temp and fume exhaust, but it's not perfect. 40c at best.

A design like the Voron2 or RailCore II that are designed from the ground up for enclosure would be perfect... if you want another new printer.

-

@phaedrux said in Motor noise and print quality:

@sethipus The DBot isn't a very good candidate for enclosure. It's way more work than it's worth IMO. I've made do with a plastic shroud that can hang around the entire printer on it's stand. It's like a loose curtain. At the top is an exhaust duct. It works fairly well with ASA, etc, both with chamber temp and fume exhaust, but it's not perfect. 40c at best.

A design like the Voron2 or RailCore II that are designed from the ground up for enclosure would be perfect... if you want another new printer.

I totally hear ya. I do want to move my power supply out of the build area, and I could design a new Duet Wifi controller box that hangs off the side rather than being centered within the left-side frame. I think I could get the bottom enclosed, the sides, front, and rear without too much trouble. The top might be "well enough" enclosed with a little plastic bag-like tent that is tall enough not to disturb the bowden tube. You're 100% right that it's not optimal at all, but I think it could be done. I've got parts (including parts on my printer) that are from ASA, but I've struggled a lot with it warping. My attempts at PC blends almost all ended in warped parts. I even had PC-blend parts that stuck to the bed throughout the print, were annealed in place by placing a cardboard box over the completed print and allowed to heat-soak on the build plate for a couple hours, cool down slowly, and then literally warped after I removed them from the build plate. Other than nylon, I've all but given up the other filaments other than PLA and PETG until I can get my printer enclosed.

I'll have to look at those other designs and decide if I need to have another printer project in my future.

-

@grizewald , I replaced all my toothed idlers with smooth ones, put the flip in the belt on the first run from the stepper on the "outside" runs of my CoreXY system so that the flat side of the belt is always bearing on the idler pulleys, and just finished my first print with it.

The flip made a ginormous difference in the surface quality, and utterly eliminated the "corduroy effect" I was seeing. I'm absolutely kicking myself that I didn't do this when I built the printer in the first place. It's unbelievable. Oh well, you live and learn.

Here are two photos of a relatively innocuous portion of a particular figure. The blue one is the new print with the flipped belts and smooth idlers, the clear one is with the belts not flipped and the teeth rolling over toothed idlers.

As you can see, in the photo of the blue print all of that corduroy effect is completely gone. That corduroy effect has afflicted every print I've ever made on this printer until now. On highly detailed models with no or few flat or relatively flat surfaces, or with filament that doesn't reflect light that much, it wasn't really noticeable. On shiny flat surfaces it was always highly obvious. I almost can't even believe how much of a difference it's made.

-

@Sethipus already shoved the cause, effect and solution. I build pick and place machines, and one of my prototypes had GT2 belt going around a smooth idler with teeth towards inside. My machine has a microscope looking at the work surface and software to measure position relative to a mark, so I could measure this. FYI, the effect is about 0.01 - 0.015mm max. I would predict that it is visible on a shiny surface, as beautifully demonstrated above.

-

@sethipus That's a very conclusive result!

My efforts to add a twist to the belts ran into a few snags. First I noticed that the clamp which holds my hot end had broken (at the rear where it wasn't visible until I took the printer apart in preparation for twisting the belts), so I had to print a new one in PETG this time to make it less likely to happen again.

Then I needed to redesign my part cooling duct so that I could get better access to the eccentric nut which tightens the hot end carriage wheel against the v-slot profile.Both new parts took a few attempts to get just right and that took up most of my weekend.

I finally got everything back together today and I'm re-printing the test piece now.

Noise figures bear out how much noise was being created by the belt teeth running over the idlers. Now I'm getting:

60mm/s 53.1 dbA

90mm/s 53.6 dbA

120mm/s 54.9 dbAPictures to follow once the print completes!

I noticed that the 0.9 degree steppers get fairly toasty compared to the 1.8 degree ones. Half way through the print, I'm seeing 41C on the motors. I'm running them at 1.6A (80% of rated current).

-

@grizewald said in Motor noise and print quality:

I noticed that the 0.9 degree steppers get fairly toasty compared to the 1.8 degree ones. Half way through the print, I'm seeing 41C on the motors. I'm running them at 1.6A (80% of rated current).

if your parts that hold the motors can take this, its not a problem

-

@veti They seem to have stabilised at 41C and the motors are mounted in metal brackets, so no problem at all.

-

@sethipus What are the diameters of the toothed and smooth idler pulleys? I use F608 bearings (22 mm diameter) for idlers in my corexy machine, with no twists in the belts, and never see that type of artifact.

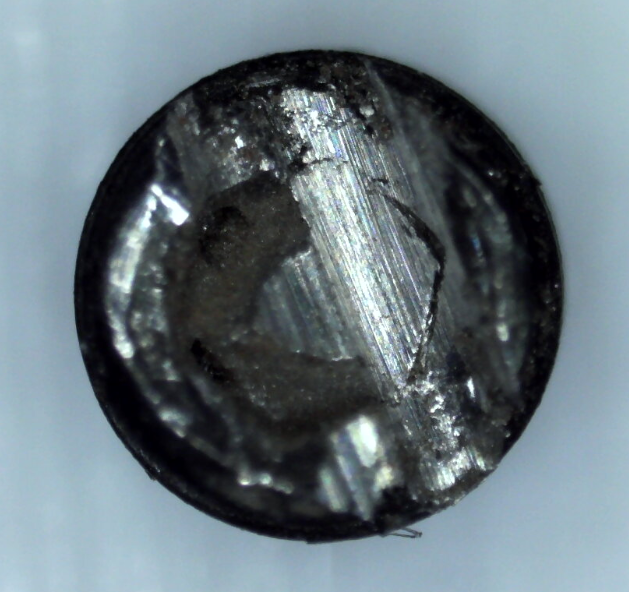

I recently had some of the fine vertical lines appearing in prints in a printer at the Makerspace (SoM), which I recently converted to a Duet WiFi controller. I noticed that the X axis was making quite a bit of noise, as if something was vibrating. After playing with current and ustep ratios, without any improvement, I took it apart to find the problem and discovered that the motor had developed excessive stiction. I thought there might be crud in the top bearing as the shaft was pointing upward, but when I opened the motor and tried spinning the bearings, both turned freely. Close inspection of the rotor found a couple small ferrous metal flakes stuck to them- I suspect they came out of the bearings. There's very little clearance between the rotor and stator, so it doesn't take much to get between them and cause exactly this sort of problem. Once I cleaned everything up (and inspected under a microscope) and reassembled the motor, no more vibration, and no more vertical lines in the prints. This is an industrial surplus motor, so there's no telling how much use it saw before it went into the printer. I put the motor back into the printer and ordered replacement bearings.

-

There is certainly an improvement, but it's not dramatic:

.jpg)

The 120mm/s section still appears to be the smoothest but the most obvious improvement is in the 60mm/s sections which apart from the ringing patterns created by acceleration show no signs of the banding which was there before.

-

@grizewald said in Motor noise and print quality:

@sethipus That's a very conclusive result!

My efforts to add a twist to the belts ran into a few snags. First I noticed that the clamp which holds my hot end had broken (at the rear where it wasn't visible until I took the printer apart in preparation for twisting the belts), so I had to print a new one in PETG this time to make it less likely to happen again.

Then I needed to redesign my part cooling duct so that I could get better access to the eccentric nut which tightens the hot end carriage wheel against the v-slot profile.I ran into a huge snag too. When I replaced my toothed idlers with smooth ones, I also replaced the corner brackets with ones that allowed both pulleys to be replaced without disassembling the printer (for some reason the original D-Bot corner brackets require disassembly to swap out one of the pulleys). The remixed corners I used also stuck down about 20mm or so further along the frame rails. For some reason I overlooked the fact that my Z-axis end stop no longer would fit where it had previously been mounted. Long story short, some severe violence using a bandsaw and a drill allowed me to jerry-rig the z-stop mount enough to fit it in between the bottom of the new corner brace and the wheels of the Z-axis carriage and I'm printing, but the current z-stop mount is a total hack (literally), so I'll have to design a more graceful solution that moves the z-stop to a different location.

As far as heat goes, I've only been running my steppers at 1.1-1.2 amps, and I haven't noticed heat to be much of a problem.

@JuKu yeah I've studied my now-former corduroy effect problem under a loupe and could see that it was a very fine difference in wall thickness that's so slight as to barely effect any dimensions, but on shiny and flat objects (where they lines align) be quite visually noticeable. I'm glad that's now a former problem.

@mrehorstdmd the idlers were 16t-sized. The original D-Bot uses a pair of stacked 623ZZ bearings (flanges outwards) to act as idler pulleys. When I swapped out my toothed idlers this weekend one of the corner braces got stacked 623ZZ bearings, the other one got actual smooth 16t-sized idlers that I happened to have. If I ever design or at least build a new printer I think I'd rather use 608-sized bearings or pulleys rather than these tighter-radius ones, or at least 20t-sized ones, for the larger radius.