Extrusion Issues and Bed Leveling

-

Hi Duettiers,

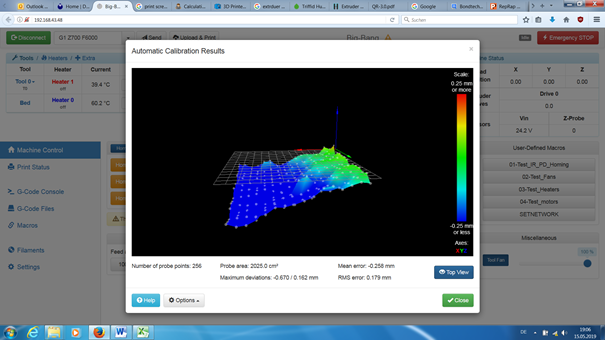

I did the auto bed leveling and I am having issue printing with a 0.8mm nozzle. I am using an E3d V6 hot end with Bondtech QR 3mm extruder. Below you can see the pictures with different print setting and bed map.

I have tired extruding through hot end and found that maximum extrusion through the hotend is limited to 5 mm /s. I have already calibrated the extruder also. What could reason for the same? I have listed the things that I know of.

- May be the maximum through put of this nozzle setup is reached at 5mm/s federate, if so it is very less to be printed at a higher speed.

- Slicer issue (but I am not sure). I used online slicer for the same https://cloud.astroprint.com is this good?

- Might the bed leveling issue

Please give your suggestion.

-

@pradeepkumar said in Extrusion Issues and Bed Leveling:

I did the auto bed leveling and I am having issue printing with a 0.8mm nozzle. I am using an E3d V6 hot end with Bondtech QR 3mm extruder. Below you can see the pictures with different print setting and bed map.

You have a significant amount of tilt in the X direction. If your printer has dual X motors, they may be out of sync. Or you may need to adjust the bed levelling screws.

I have tired extruding through hot end and found that maximum extrusion through the hotend is limited to 5 mm /s.

If the nozzle of your printer is 0.4mm then that is a respectable extrusion rate. You don't need more.

-

@dc42 David - he said he's using a 0.,8mm nozzle.

@Pradeepkumar Using a 0.4mm nozzle then the best print speed you might expect with a standard V6 would be around 80mm/sec - possibly only 60mm/sec (assuming a layer height of around 0.3mm) and depending on filament type and a few other factors. BUT, a 0.4mm diameter nozzle has an area of around 0.12mm^2 and a 0.8 mm diameter nozzle has an area of around 0.5mm^2 which is about 4 times larger. Therefore, to get the same filament flow rate, you need to print 4 times slower. So the best speed you might expect would be around 20mm/sec. If you use a layer height more than 0.3mm, then you'll need to print even slower so around 10 to 12mm/sec is probably reasonable.

The other thing is that when you start to extrude this sort of volume of filament, you need to use much more part cooling and drop the bed temperature too. You'll have more luck printing larger parts because the filament will have more time to cool before the next layer. Attempting to print something as small as a 20mm cube with a 0.8mm nozzle is pushing things. You'd likely need to print much slower than even 10mm /sec to give the filament time to cool.

So sort out you bed levelling. Then try printing with a bed temperature of around 40 degrees C, at a speed of no more than about 10mm/sec and use lots of part cooling air.

-

@deckingman I can not thank you enough. The suggestion that you gave worked out well. First i have levelled the bed and reduce the print speed to 10 mm/s. Also used the cura slicer to slice the parts (may be the online slicer did not work well).

And i really love the surface finish from the Filabase, it is awesome.

I know it still few adjustment, But good to see something for the first test. This print stop due faulty e3d thermistor, but fixed it by shaking, need to change this also.

Have nice weekend.

-

@pradeepkumar That's looking a lot better. Glad I could help.