Delta calibration failed

-

What is the maximum number of points we can set for probing ?

Does it make sense if I use the maximum ? -

Maximum points in bed.g is 32. Using more points helps if your height map shows substantial errors in places well away from your existing probe points.

-

Hello !

Using this awesome tool http://escher3d.com/pages/wizards/wizardbed.php , I set 10 points on edge, 3 half way and 1 in the centre.G30 P0 X0.00 Y110.00 Z-99999 H0 G30 P1 X70.71 Y84.26 Z-99999 H0 G30 P2 X108.33 Y19.10 Z-99999 H0 G30 P3 X95.26 Y-55.00 Z-99999 H0 G30 P4 X37.62 Y-103.37 Z-99999 H0 G30 P5 X-37.62 Y-103.37 Z-99999 H0 G30 P6 X-95.26 Y-55.00 Z-99999 H0 G30 P7 X-108.33 Y19.10 Z-99999 H0 G30 P8 X-70.71 Y84.26 Z-99999 H0 G30 P9 X0.00 Y55.00 Z-99999 H0 G30 P10 X47.63 Y-27.50 Z-99999 H0 G30 P11 X-47.63 Y-27.50 Z-99999 H0 G30 P12 X0 Y0 Z-99999 S9Autocalibration result:

G32 Calibrated 9 factors using 13 points, deviation before 0.075 after 0.067Height map result

This gives different result, but that still sounds not very good

-

@viald I notice that you are using S9 on the last line of your G30's in the bed.g file I think you would do better if you changed that to S6 or S8 S7 and S9 will auto adjust the arm lengths for a best fit and we know that isn't always optimum as I am sure DC will explain.

Just my thoughts.

Doug

-

Thank you Doug.

Here is the result with S6

Unfortunately, almost the same.

-

@viald that's not actually auto calibration tho that is the result of mesh bed compensation!!

-

You are right, this is the height map calculation after the auto calibration I did

What information do you what about the autocalibration ? -

Finally, I set 19 points, 12 on edge, 6 half way and 1 in the center. I also add the trigger height for each point in real condition (head at 210° and bed at 65°)

G30 P0 X0.00 Y110.00 Z-99999 H-0.092 G30 P1 X55.00 Y95.26 Z-99999 H-0.024 G30 P2 X95.26 Y55.00 Z-99999 H-0.005 G30 P3 X110.00 Y0.00 Z-99999 H-0.073 G30 P4 X95.26 Y-55.00 Z-99999 H0.03 G30 P5 X55.00 Y-95.26 Z-99999 H0.011 G30 P6 X0.00 Y-110.00 Z-99999 H0.026 G30 P7 X-55.00 Y-95.26 Z-99999 H0.029 G30 P8 X-95.26 Y-55.00 Z-99999 H0.015 G30 P9 X-110.00 Y-0.00 Z-99999 H-0.039 G30 P10 X-95.26 Y55.00 Z-99999 H-0.011 G30 P11 X-55.00 Y95.26 Z-99999 H-0.072 G30 P12 X0.00 Y55.00 Z-99999 H-0.05 G30 P13 X47.63 Y27.50 Z-99999 H-0.015 G30 P14 X47.63 Y-27.50 Z-99999 H-0.009 G30 P15 X0.00 Y-55.00 Z-99999 H0.014 G30 P16 X-47.63 Y-27.50 Z-99999 H0.010 G30 P17 X-47.63 Y27.50 Z-99999 H-0.025 G30 P18 X0 Y0 Z-99999 S6What do you think about the trigger heights ? Is it necessary to add it ?

Here the autocalibration log

Calibrated 9 factors using 19 points, deviation before 0.067 after 0.062The same using S6

Calibrated 6 factors using 19 points, deviation before 0.065 after 0.064I don't know what this information means, what could be the conclusion ?

As Doug said, what is the difference between S6/7/8/9 in G30 command ?Thank you.

-

It seems to be good

-

In fact, the first layer is still no so good, so I still try to improve the precision of the Delta.

I have completely disassembled the delta and check each part.

I have rebuild it, calibrated again and again for in fact having the same poor calibration resultG32 Calibrated 6 factors using 19 points, deviation before 0.068 after 0.067

The default seems to be symmetrical and I have absolutely no idea where it comes from.

I switched the connection of the stepper and end switch on the board, X ->Y, Y->Z and Z->X, and did another calibration.

I supposed that the height map will also rotate 90°, actually not, the height map has exactly the same symmetrical default in the same direction

What could it mean ? This Delta makes me crazy

-

check out http://boim.com/DeltaUtil/CalDoc/Calibration.html for possible reasons for deviation.

-

Thanks. I already read this interesting information, but none of the effects exposed are precisely mine. It seems that my issue is a combination of multiple error effects.

I think, I should start with the rod length effect. I should precisely manually measure each of them, and check is they are equal.

But they are about 290mm long and my caliper is not large enough

-

@Viald, have you read https://duet3d.dozuki.com/Wiki/Calibrating_a_delta_printer#Section_Make_sure_your_build_is_accurate ? A circular (bulls-eye) spirit level mounted on the effector will show up many types of geometric error that can cause height variations.

-

Yes I read it several times. The bulls-eye spirit level is a very good idea, If the result is not correct, I think It won't be easy to interpret the feedback.

If the bubble is fixed during effector mouvements, the issue clearly comes from the bed, at the opposite it could comes from too many things.I'm currently trying to compare rods length with a micrometer. I'm going step by step, because I'm lost.

-

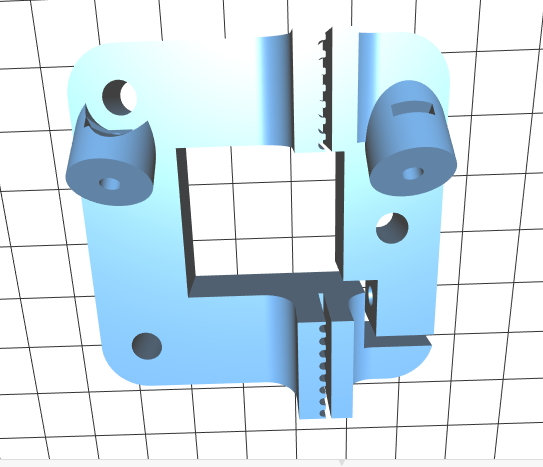

As my caliper is not large enough to measure the magnetic arms length, I made this tool to compare the length.

I took one arm length as a reference and compare it to others, here is the result:

1/ Ref (0.00)

2/ +0.02

3/ -0.03

4/ -0.04

5/ 0.00

6/ 0.00I guess that this is good enough, and my issue does not come from the arms length.

Arms are good

To check if the autocalibration is correct, I measure as precise as possible the length in 3 parts

The sphere diameter is 9.41, so the arm length is 213.64 + 42.55 + 42.53 - 9.41 = 289.31

The autocalibration (S7) always find a longer length around 291.786M665 Diagonal 291.786, delta radius 171.632, homed height 229.294, bed radius 114.0, X -0.180°, Y -0.129°, Z 0.000°So I decided to fixe the real length in config.g and did multiple S6 autocalibration

That's the best I can have:G32 Calibrated 6 factors using 19 points, deviation before 0.078 after 0.077M665 L289.300 R170.748 H229.244 B114.0 X-0.167 Y-0.125 Z0.000 M666 X0.135 Y0.152 Z-0.287 A0.30 B0.19@dc42 I bought circular spirit level, I first checked the bed level which is perfect.

Check the video https://dai.ly/k4fXd07BAdjzOztaR39Bed is good

Then I put the level on the effector, adjusted its level at X0 Y0 and move to each tower, below is the result:

The video link https://dai.ly/k50wYDzWkYziSLtb1Nv

What ever the Z position is, I have exactly the same levelling, and moving along the Z axe, the levelling does neither not change.

But, actually the effector is tilting when it's close to each tower. For sure this is the issue, but where does it come from ?

Thanks for your help.

-

And Voilà !!!!

Look at this That's much better compare to the previous one :))

That's much better compare to the previous one :))G32 Calibrated 7 factors using 19 points, deviation before 0.022 after 0.021M665 Diagonal 289.536, delta radius 170.580, homed height 229.474, bed radius 114.0, X -0.089°, Y -0.175°, Z 0.000°And the rod length is quite the same compare to measurement I did.

The distance between balls of the carriage and balls of the effector was not the same. The max difference was 0.9mm

The carriages of my printer have a screw to tight them much or less on the V-slot profile. But when you tight them you change the distance between the 2 balls, which cause a major issue on the geometry of the printer.

I still have a small tilt effect on the effector, but I think that the precision should be now enough to print large parts.

I'll give a try and let you know. -

The result is better, mostly for the first layer but it could be improved further.

What are the other reasons which can tilt the effector ?I have printed a large rectangular object which should measure 120x170mm, but in fact the print is smaller and not rectangular, the shape is trapezoid

Only the height is correct. -

@viald said in Delta calibration failed:

What are the other reasons which can tilt the effector ?

The common reasons are listed at https://duet3d.dozuki.com/Wiki/Calibrating_a_delta_printer#Section_Make_sure_your_build_is_accurate.

-

Step by step checks

Towers must be parallel to each other

My Delta has metal corners. I have checked spacing with a caliper at bottom, top and half way. the max difference between 2 towers is less than 0.2mmBed should be at right angles to the towers in both X and Y directions

I have checked with a square, the bed is perpendicular to the 3 towersAll 6 rods must be the same length, measured between bearing centres

Checked, see above.The spacing between the bearings at the top of a pair of rods must be exactly the same as the spacing between the bearings at the bottom

Corrected, see aboveThe joints must have enough angle of movement to allow the nozzle to reach all of the printable area

I use magnetic balls, not an issue.The two bearings on each carriage must be at the same height

Should be by design, I don't know how to check.Carriages must not be rotated or warped about the Z axis

It should not be my case. Check the video with the bulls-eye level. I suppose If one of the carriage has this issue, the level should move during mouvement along the Z axe.There must be no play in the joints

I use magnetic ballsI have printed this calibration tool https://www.thingiverse.com/thing:745523

M665 L289.536 R170.677 H227.388 B114.0 X-0.504 Y-0.516 Z0.000

It seems that autocalibration failed to correct the Y tower position. And it seems that I have a rod length error as well, but all lengths are equal

-

Now that you have corrected the rod bearing spacing, what does the spirit level show?