An alternative to z-hops for delta kinematics

-

I'm looking for some feedback from more experienced printer builders/tinkerers on the feasibility of the following.

Given how a delta works when making planar moves, i was thinking about an alternative to using z-hops that would avoid the extra g-code, interruption of movement, and maybe reduce the need for retraction for travel moves across a print surface.

When making a X/Y move on a delta, there'a always at least one carriage moving downwards. If the software was to ever so slightly delay the movement of the downwards-moving carriage, the result would be a move with a slight upwards curve in the Z-axis.

Has there been a delta firmware that does this? Are there undesirable sideeffects to making the nozzle move over the print in a curve? Anyone got some input on this?

-

I had a similar idea 2 or 3 years ago, although my plan was to split the move into 2 parts with a greater Z coordinate at the join. Or possibly use a single move with a quadratic Z term added.

-

Hope I understand correctly what you are contemplating. Kisslicer has an option to curve the start and stop of a zhop. I've found (I print with PETG most of the time) that it doesn't cleave (for want of a better word) the filament as well as a straight up zhop so leads to stringing easier.

-

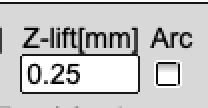

The new version of KISSlicer actually has this as an option so there may be something to it.

-

This "Arc" Z-hopping would be interesting to try on any kinematics.

-

@edgars-batna said in An alternative to z-hops for delta kinematics:

This "Arc" Z-hopping would be interesting to try on any kinematics.

Yeah I agree, regular z-hop increases stringing (especial on bowden systems) the arc solution could be better in that meter. And it would require less fast z-axis then regular z-hop.

Would be nice to see that implemented in firmware retraction on Duet. -

@dc42 said in An alternative to z-hops for delta kinematics:

I had a similar idea 2 or 3 years ago, although my plan was to split the move into 2 parts with a greater Z coordinate at the join. Or possibly use a single move with a quadratic Z term added.

Do you have any plans for revisiting this?

@edgars-batna said in An alternative to z-hops for delta kinematics:

This "Arc" Z-hopping would be interesting to try on any kinematics.

Certainly, though the point here was that a delta may provide this in an easier way to implement, simply through timing and without additional movement.

-

@naqaj said in An alternative to z-hops for delta kinematics:

...i was thinking about an alternative to using z-hops that would avoid the extra g-code, interruption of movement, and maybe reduce the need for retraction for travel moves across a print surface.

What in your opinion would be the benefit of that, except for the savings in gcode? The only benefit of a delta regarding Zhop is that it can do that REALLY fast compared to a moving bed. The benefit there is that, if tuned right, it can Zhop so fast that it breaks the string BEFORE the nozzle moves in the XY-plane. Besides that zhop-less movements are less stringy than moves with zhop, any technique that moves in XY during zhop would in my view INCREASE stringyness.

-

@deltacon said in An alternative to z-hops for delta kinematics:

@naqaj said in An alternative to z-hops for delta kinematics:

...i was thinking about an alternative to using z-hops that would avoid the extra g-code, interruption of movement, and maybe reduce the need for retraction for travel moves across a print surface.

......The only benefit of a delta regarding Zhop is that it can do that REALLY fast compared to a moving bed. The benefit there is that, if tuned right, it can Zhop so fast that it breaks the string BEFORE the nozzle moves.......any technique that moves in XY during zhop would in my view INCREASE stringyness.

That has been my experiance trying arc z hop in Kisslicer, stringing that I don't get with regular z hop.

-

@deltacon Can you elaborate on "REALLY fast"? My bed and travel are very fast on my CoreXY, it pains me to watch them waiting for eachother.

-

@edgars-batna

Since the buildplate does not move on a delta, there is very little mass involved in a Z move. Besides that the mass is moced by 3 stepper motors simultaneously. All three arms move up identically during a Z hop. Most CoreXY printers use leadscrews which move the bed pretty slow and certainly not quick enough to snap the thread. On my Rostock I've set Z-move to 10.000 or something. It is probably limited by other factors, but it gives a real good "Clunck" sound at each retraction