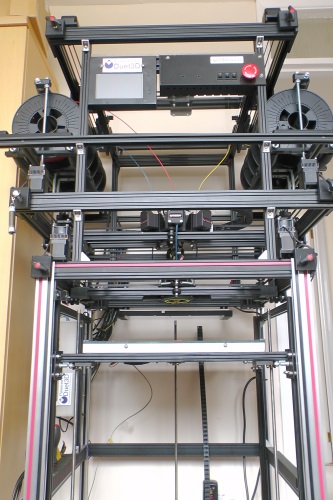

CoreXYUV with dynamic load\force balancing.

-

Wow!!!

-

Here is another.

Somewhere in there is a hot end - honest.

-

Not sure what you are doing but as always I'm sure it will work well.

I'll be following your blog on this for sure.

Great job Ian!

-

@deckingman would be better for the mass do be as close as possible with the opposed moving mass. Or you will induce some momentum and even if it balancing translation will induce rotational vibration!

For example: have a pair of wheights, for each axis, at the mid level of your double corexy system.

-

@brunofporto said in CoreXYUV with dynamic load\force balancing.:

@deckingman would be better for the mass do be as close as possible with the opposed moving mass. Or you will induce some momentum and even if it balancing translation will induce rotational vibration!

For example: have a pair of wheights, for each axis, at the mid level of your double corexy system.

Yeah, I know that and I'd thought about it but the filaments get in the way. There is no way that I could have moving weights between the extruders and the hot end because they would tear the Bowden tubes out if you think about it. In fact, the moving counter weights have to go above the 5 filament paths.

Anyway, all will be revealed in my blog and video.....

-

@timcurtis67 said in CoreXYUV with dynamic load\force balancing.:

Not sure what you are doing but as always I'm sure it will work well.

I'll be following your blog on this for sure.

Great job Ian!

Cheers - and oh yes, it works!

-

@deckingman You do not need to use a coreXY system for this. The masses can be at the sides, and the motors itself can be part of the moving mass for this

Something like this:

-

ps.: just an idea. I am a fan of your designs

-

@deckingman Looks exciting, I look forward to the video and blog post!

-

@brunofporto said in CoreXYUV with dynamic load\force balancing.:

@deckingman You do not need to use a coreXY system for this. The masses can be at the sides, and the motors itself can be part of the moving mass for this

Something like this:

It might work if you could sort out the kinematics. It'd be a kind of CoreXYUV with additional Cartesian. Although I'm not convinced that it would work.

For the CoreXYUV, there is a given mass to be moved in X. In the Y direction, there is an additional mass of the X rails and the Y gantry plates. So the total mass to be moved in Y is the X mass plus the addition.

For the counter weights, the two weights at the front and back would have to have a combined weight equivalent to the CoreXYUV mass in X. And two weights at either side would have to have a combined mass equal to the CoreXYUV mass in X plus the addition for Y. This works fine for pure X and pure Y moves. But what happens when you move diagonally from say the front left corner to the right rear? All 4 weights would move in the direction of the opposite corner. So you'd be moving twice the X mass plus the addition for Y. Maybe that gets cancelled out by the fact that the CoreXYUV moves greater distance in Y than the two Cartesian weight axes? This is where my ageing brain starts to give up...........

-

@deckingman Basically there is nor problem with the foce balancing mass to be different from the core system. It is even better if it is more massive - it will need smaller movements to counter the movement of the corexyu

BUT......

You already have it working so was just food for thought

By the way.... Using a diamond hotend with multiple extruders to overcome the extrusion limits of conventional hot ends is just brilliant. I think you set an industry standard with that - no need for bigger filament, can work with small volume of extrusion, solve the issue of heat transfer to fuse the filament... etc etc etc.... It is just the simples and best way to do it!!!

-

@brunofporto said in CoreXYUV with dynamic load\force balancing.:

@deckingman

................By the way.... Using a diamond hotend with multiple extruders to overcome the extrusion limits of conventional hot ends is just brilliant..............Thanks. I'm glad someone finally gets it - I've been banging on about it for quite while but nobody takes much notice.

So yes, with 3 melt chambers you effectively triple the surface area between hot surface and filament. Plus, for a given amount of filament coming out of the nozzle, each filament fed in moves at 1/3rd the speed of a single filament in a single melt chamber (assuming equal mixing ratios are employed) so each one spends longer in the melt zone. Increased contact area plus increased time in contact leads to much higher melt rate.

This load/force balancing exercise is all part of a wider strategy I have in mind to see just what sort of print speeds are possible. Until a few months ago, I had issues with pressure advance during arc moves, so couldn't use it but this is now resolved. Watch this space............. -

@deckingman said in CoreXYUV with dynamic load\force balancing.:

For the counter weights, the two weights at the front and back would have to have a combined weight equivalent to the CoreXYUV mass in X. And two weights at either side would have to have a combined mass equal to the CoreXYUV mass in X plus the addition for Y. This works fine for pure X and pure Y moves. But what happens when you move diagonally from say the front left corner to the right rear? All 4 weights would move in the direction of the opposite corner. So you'd be moving twice the X mass plus the addition for Y. Maybe that gets cancelled out by the fact that the CoreXYUV moves greater distance in Y than the two Cartesian weight axes? This is where my ageing brain starts to give up...........

You need to think in term of acceleration, not distance. I think it is equivalent, but I didn't do the maths (you just need to do X/Y projections and compare).

Anyway, your setup is really impressive! And if it work, don't fix it

-

@fma said in CoreXYUV with dynamic load\force balancing.:

You need to think in term of acceleration, not distance. I think it is equivalent, but I didn't do the maths (you just need to do X/Y projections and compare).

Anyway, your setup is really impressive! And if it work, don't fix it

It's the mass I was wondering about. As it stands, the mass in X is 2340 gms. The additional mass in Y is 1866 gms. So the total mass in Y is 4206 gms. To compensate for the force exerted in X, the front and back weights in that diagram would have to add up to 2340 gms. To compensate for the mass in Y, the two side weights would have to add up to 4260 gms. So for a 45 degree move of the CoreXYUV gantries, the force would some sort of vector of 4260 gms (maybe) x acceleration. But all 4 side weights would move toward the opposite corner, meaning that the total compensating mass would be 2340 plus 4260 = 6546 gms. So if the acceleration for those weights was the same (which I think it would need to be), then the compensating force would be much higher than needed. (I think). But there are complications of vectors and different move distances which my ageing brain can't be bothered to look into.

Anyway, what I have come up with works, so that's good enough for me.

-

As promised. For anyone who's interested, you can read the waffle here https://somei3deas.wordpress.com/2018/10/04/dynamic-force-cancellationload-balancing/

and you can watch the video here https://www.youtube.com/watch?v=HS7LvcBowCA

The video is fairly well annotated so should work "stand alone" if you don't want to read the waffle. Or if you want to do both, there is a link to the video at the end of the blog post.

-

First, you video of gantry assembling is very cool

And the result is amazing! Well done.

-

Wow that worked out great. Have you noticed a difference in surface finish? ie, ringing?

-

That is wonderful............. speechless!

Well.... Five extruders, Diamond 5x hot end.... active dampening..... Some 500mm/s printing tests soon?

-

https://www.youtube.com/watch?v=dd5WqmWIRzw came this in mind

But these buildings dampeners are passive

But these buildings dampeners are passive -

@brunofporto Except Deckingmans printer is only slightly less massive than that 700 ton ball.