Meaning of low/high slip angle in EMF Calculator

-

Maybe this is due to the fact that I am not a native English speaker and this goes beyond my engineering-related vocabulary but I have no real interpretation of what the low and high slip angle mean.

If I enter the specs and current settings of my e.g. X/Y axis into the calculator I get

Speed at which torque starts to drop (low slip angle): 106.9 mm/s @ 10.7 kHz Speed at which torque starts to drop (high slip angle): 138.8 mm/s @ 13.9 kHzI set requested max speed to 120 mm/s. So what does this tell me now? Can I go 106.9 mm/s or 138.8 mm/s?

I tried to search the forum about this but I did not find anything that really explained the meanings of these two different values and how to interpret them.

In case the specs are required to better answer this question:

- Cartesian

- 12V

- Motor current: 450mA

- Motors in series: 1

- Step angle: 1.8°

- Rated torque: 40Ncm

- Rated current: 900mA

- Phase resistance: 4.4Ohm

- Phase inductance: 10mH

- Steps/mm: 100

-

Slip angle is the difference between where you have commanded the motor to be and where it actually is. High slip angle is just below 2 full steps, at which point if it increases any more the motor will skip 4 full steps.

-

@dc42 I'm sorry, but I still don't really get it.

Or the other way around, here is what I now understand from your response (regarding low slip angle):If I tell my motor to move e.g. the X axis 200mm with 120mm/s it will actually only move the distance that it would have traveled in the same amount of time with 106.9mm/s. Therefore it would have only traveled 180mm instead of the desired 200mm. In actual printing situation this would lead to (in this case) massively shifted layers.

Did I understand this correctly? If not, can you please provide an example.

-

When a stepper motor is accelerating, it has to produce torque to overcome the rotor inertia and the mass of whatever the motor is moving. When moving at a steady speed, it needs torque only to overcome friction and air resistance.

The motor current tells the stepper motor rotor where it should be in relation to the poles (i.e. the rotor angle). When the motor is at that position, there is no torque, so the motor stays in that position until the current is changed to tell it to move to a different position.

The motor produces torque when the actual motor position (i.e. rotor angle) is different from the position commanded by the current. The angle between the actual rotor position and the commanded rotor position is the slip angle, or lag angle.

So it follows that whenever the motor is generating torque in order to accelerate something or even just to overcome friction and air resistance, the slip angle is nonzero in order to produce the required torque. The greater the torque demanded, the greater the slip angle.

The phase of the back emf due to rotation relative to the current changes with the slip angle. At low slip angles, it is in phase with the inductive back emf (90 degrees out of phase with the current). At high slip angles, it is in phase with the back emf. That is why the calculator gives you two values for the maximum speed before the available torque starts to drop.

Does that help?

-

I think I just understood it (more or less) while writing this reply (I deleted what I just wrote

)

)This is what I understood now:

Important to all of this is additionally always the relation between required torque (due to inertia, weight of the object to move, friction, air resistance and maybe also back EMF) and the torque that the motor is able to produce at the set current. As long as the former is less than the latter everything is fine. Problems only occur when this flips over. This can be due to the motor loosing torque because back EMF is working against it or due to any increase in resistance of any kind. I hope this is right so far.What the two values of the calculator will tell me basically how much steps I will lose if the motor can no longer produce the required torque. At the low slip angle this would be one step (or two?) and at the high slip angle already four steps (and I assume this will rise very fast to a point where the motor is not moving anymore at all).

This means if I am risky I can just leave my max speeds (taken from Marlin's config for Anet A8) at 400mm/s and when the slicer tells my printer to move at travel speeds of 120mm/s (which falls in between the two slip angle speeds) everything could be fine or I will loose something between one and four steps if something goes wrong and thereby will see shifted layers, right?

-

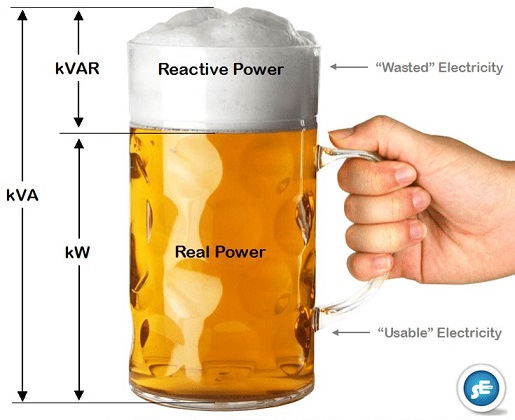

@dc42 awesome explanation, similar to the relationship of power factor caused by inductance, you just need to make a cool analogy to describe it like.......

-

@dc42 Meanwhile I realized that I did understand your explanation regarding what a low and what a high slip angle is, while reading your post, but when it came to understanding the values from the calculator my brain dropped that info and wanted to turn this again into some kind of lower-/upper bound.

After thinking again about it for a while, I think the following will come closer to it:

Low slip angle (at high-ish speeds) will occur as part of steady movement as the motor will mainly only have to overcome friction and air resistance. High slip angle (again at high-ish speeds) will occur as part of accelerations where more torque is required to get even faster.In my case where I wanted to go 120mm/s and the high slip angle is a little below 140mm/s I now interpret this as: I will not have problems to accelerate to 120mm/s. But then traveling at a steady 120mm/s the low slip angle of close to 107mm/s could become a problem once the resistance rises out of any reason.

Did I get this right this time? Sorry if I bother you with this but I really want to understand this.

-

The main takeaways from the calculator are:

-

Printing speed should not exceed the maximum speed for low slip angle, otherwise accuracy may suffer.

-

For travel moves, if you want to exceed the maximum speed for high slip angle given by the calculator, you may have to reduce acceleration because of the reduced torque available.

-

-

@dc42 That was exactly the information I was looking for! Thank you very much!

-

And how is this connected to missing steps detection? When my high slip is about ~120mm/s and I use travel at ~500mm/s can I still use missing steps detection?

As far I read this is not possible but what does this mean? Will I get false triggers during travel moves or will missing steps detection just not detect skipped steps when doing travel move? -

For missed step detection to work, you need to keep the speed below the "low slip angle" maximum speed.

-

undefined Phaedrux referenced this topic

undefined Phaedrux referenced this topic