PanelDue 7 loses macros after homing or moving rotary axes A/B

-

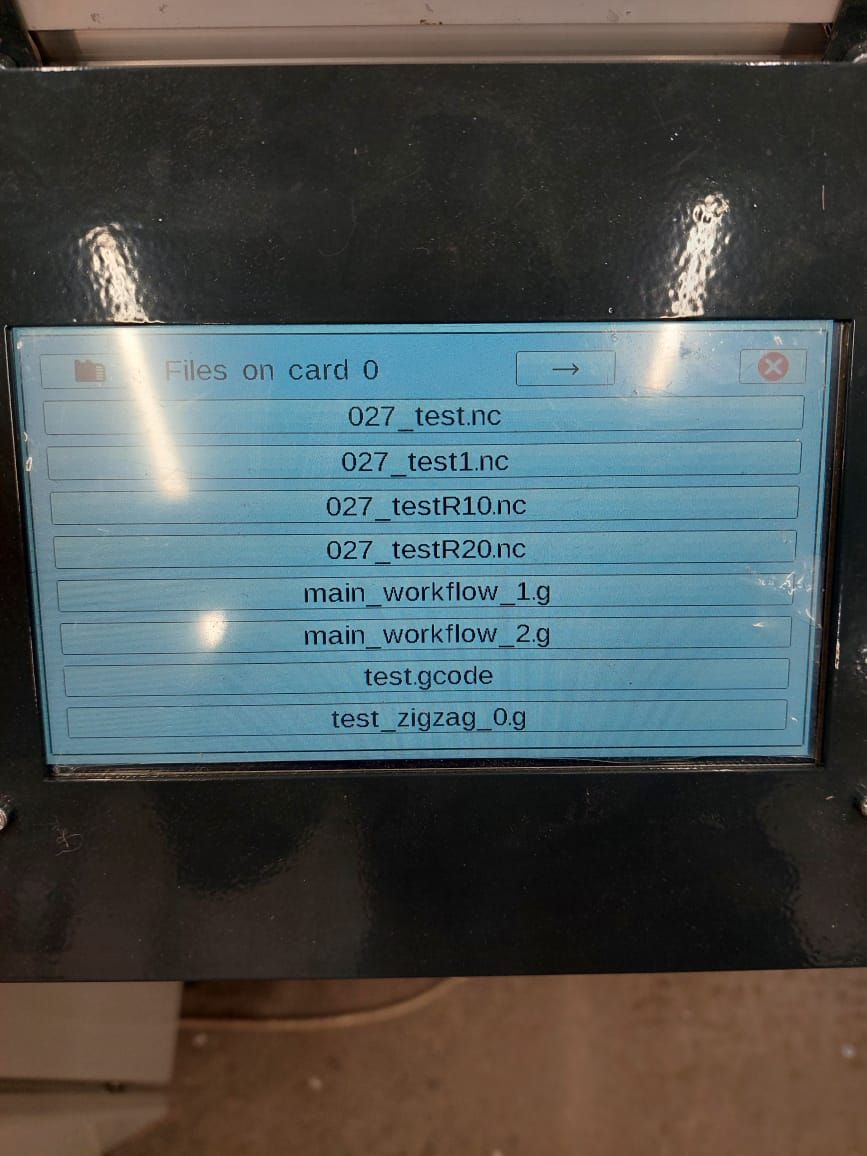

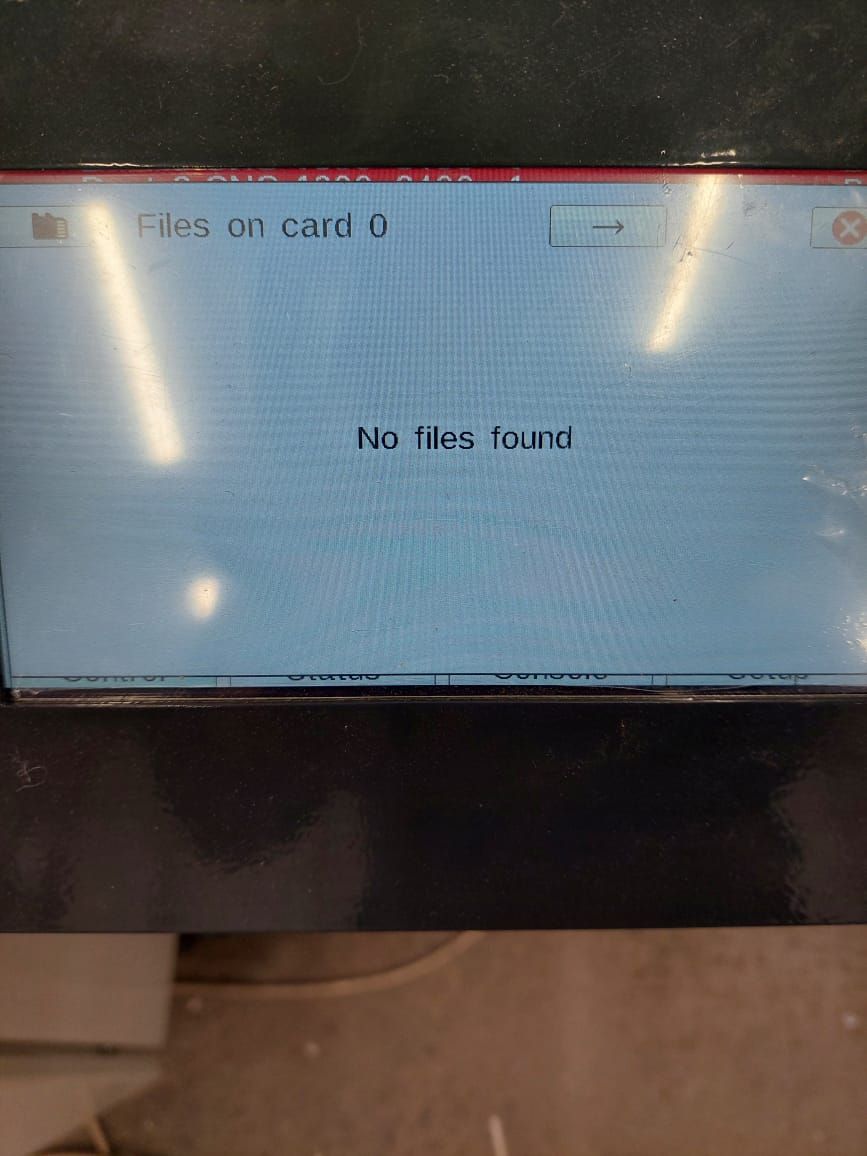

Good afternoon I put the images before moving the rotary axis and after

-

@Stanislav which version of PanelDue firmware are you running?

-

Version of the firmware PanelDueFirmware-5.0i-7.0i.bin

-

Panel Due firmware 3.5.1-5.0i-7.0i

-

I also noticed that after moving the rotary axis, files from cd card disappear

-

@Stanislav please post you full config.g and homing macros

-

I attached files config.g homea.g homeb.g

; Configuration file for RepRapFirmware on Duet 3 Main Board 6HC ; executed by the firmware on start-up ; ; generated by RepRapFirmware Configuration Tool v3.5.4 on Wed Jan 22 2025 10:58:40 GMT+0200 (Восточная Европа, стандартное время) ; General G90 ; absolute coordinates M83 ; relative extruder moves M550 P"Duet 3-CNC 1600_2400 v1" ; set hostname M501 ; Logging Configuration Section ; This section sets up event logging to an SD card file. ; Logs will record important events such as power-up, print start/finish, ; and additional messages based on the selected log level. ; Enable logging for different levels M929 P"logs/eventlog.txt" S1 ; Log WARN level events to logs/eventlog.txt M929 P"logs/infolog.txt" S2 ; Log INFO level events to logs/infolog.txt M929 P"logs/debuglog.txt" S3 ; Log DEBUG level events to logs/debuglog.txt ; Accessories M575 P1 B57600 S1 ; Make sure PanelDue is connected with error control ; Network (Ethernet) M552 P0.0.0.0 S0 ; enable Ethernet M586 P0 S1 ; enable HTTP ; Network (Wi-Fi Access Point) M552 I1 S0 ; Disconnect Wi-Fi G4 S5 ; wait 5 seconds M589 S"DuetAP" P"12345678" I192.168.4.1 ; Configure the access point M552 I1 S2 ; Turn on the access point Network M586 P0 S1 ; configure HTTP M586 P1 S1 ; configure FTP M586 P2 S1 ; configure Telnet ; Wait for CAN expansion boards G4 S2 M669 K0 ; Install the decande kinematics ; Smart Drivers M569 P0.0 S1 D2 ; driver 0.0 goes forwards (U axis) M569 P0.1 S1 D2 ; driver 0.1 goes forwards (B axis) M569 P0.2 S1 D2 ; driver 0.2 goes forwards (extruder 0) M569 P0.3 S1 D2 ; driver 0.3 goes forwards (X axis) M569 P0.4 S1 D2 ; driver 0.4 goes forwards (A axis) M569 P0.5 S1 D2 ; driver 0.5 goes forwards (extruder 1) M569 P1.0 S1 D2 ; driver 1.0 goes forwards (Y1 axis) M569 P1.1 S0 D2 ; driver 1.1 goes forwards (Y2 axis) ; Motor Idle Current Reduction M906 I50 ; set motor current idle factor M84 S30 ; set motor current idle timeout ; Axes M584 X0.3 Y1.0:1.1 U0.0 A0.4 B0.1 R0 ; set axis mapping (Z axis removed, fixed bed) M350 X16 Y16 U16 A16 B16 I1 ; configure microstepping with interpolation M906 X2800 Y5500 U2800 A1200 B1200 ; set axis driver currents M92 X29.09 Y46.3 U29.09 A35.55 B35.55 ; configure steps per mm (A and B are rotary axes) M208 X0:1700 Y0:2400 U100:1700 A-360:360 B-360:360 ; set axis limits M566 X1500 Y1500 U1500 A1500 B1500; set maximum instantaneous speed changes (mm/min) M203 X18000 Y18000 U18000 A20000 B20000 ; set maximum speeds (degrees/min for rotary axes) M201 X2000 Y2000 U2000 A5000 B5000 ; set accelerations (degrees/s^2 for rotary axes) ; Collision avoidance M597 X0 U100 ;Set the minimum distance between x and u in 100 mm ; Backlash Compensation Section M425 X0.1 Y0.5 Q1 ; Enable backlash compensation with 0.1mm on X and 0.5mm on Y ; Extruders M302 P1 ; Allow extrusion without heating M584 E0.5:0.2 ; set extruder mapping M350 E16:16 I1 ; configure microstepping with interpolation M906 E800:800 ; set extruder driver currents M92 E19.28:19.28 ; configure steps per mm M566 E120:120 ; set maximum instantaneous speed changes (mm/min) M203 E10000:10000 ; set maximum speeds (mm/min) M201 E2000:2000 ; set accelerations (mm/s^2) ; Endstops (Normally Closed Contacts) M574 X1 P"!io2.in" S1 ; configure X axis endstop (NC) низ M574 Y1 P"io3.in+io4.in" S1 ; configure Y1 axis endstop (NC) низ M574 U2 P"!io1.in" S1 ; configure U axis endstop (NC) верх M574 A1 P"!io7.in" S1 ; configure A axis endstop (NC, top position) низ M574 B1 P"!io5.in" S1 ; configure B axis endstop (NC, top position) низ ; Sensors M308 S0 P"temp1" Y"thermistor" A"Roller heating 1" T100000 B3950 C7.06e-8 ; configure sensor #0 Left carriage M308 S1 P"temp0" Y"thermistor" A"Roller heating 2" T100000 B3950 C7.06e-8 ; configure sensor #1 Right carriage M308 S2 Y"mcu-temp" A"MCU" ; configure sensor as MCU ; Heaters M950 H0 C"out2" T0 ; create heater #1 Left carriage x M143 H0 P0 T1 C0 S180 A0 ; configure heater monitor #0 for heater #1 M307 H0 R2.286 K0.230:0.000 D13.66 E1.35 S1.00 B0 V24.2 ; configure model of heater #1 M950 H1 C"out1" T1 ; create heater #0 правая каретка ось U M143 H1 P0 T0 C0 S180 A0 ; configure heater monitor #0 for heater #2 M307 H0 R2.286 K0.230:0.000 D13.66 E1.35 S1.00 B0 V24.2 ; configure model of heater #2 M143 H0 S250 ; Ограничение температуры нагревателя H0 до 250°C M143 H1 S250 ; Ограничение температуры нагревателя H1 до 250°C ; Safety ;M570 H0 P4 T15 ; Anomaly on the heater 0 should be stored for 4 seconds and be ± 15 ° C from the settings for the operation. ;M570 H1 P4 T15; Anomaly on the heater 1 should be stored for 4 seconds and be ± 15 ° C from the settings for the operation. ; Fans ;6HC M950 F0 C"out7" Q5000 ; create 6HC fan 0 on pin out7 and set its frequency M106 P0 H2 T20:20 L0.5 C"Fan 1" ; set fan 0 value. Thermostatic control is turned on, custom name "Fan 1" ;3HC M950 F1 C"out8" Q5000 ; create 3HC fan 1 on pin out8 and set its frequency M106 P1 H2 T20:20 L0.5 C"Fan 2" ; set fan 1 value. Thermostatic control is turned on, custom name "Fan 2" ; Outputs for Pneumatic Valves M950 P3 C"out6" ; Assign OUT6 for Pneumoclapan Slyport X M950 P4 C"out5" ; Assign OUT5 output for pneumatic valves of the caliper U ; Inputs for Upper Position Sensors M950 J0 C"io8.in" ; Appoint IO8. in as an input for the upper position sensor of the caliper x M950 J1 C"io6.in" ; Appoint IO6. in as an input for the top position sensor of the caliper U ; Triggers for Upper Position Sensors M581 T2 P0 S1 R0 C"io8.in" ;Tigger 2 for the top position sensor of the caliper X M581 T3 P1 S1 R0 C"io6.in" ; Tigger 3 for the top position sensor of the caliper U ; Tool configuration section ; Create a tool that uses the low end (X) carriage M563 P0 D0 H0 X0 S"Axis X" M568 P0 R0 S0 ; Create a tool that uses the high end (U) carriage M563 P1 D1 H1 X3 S"Axis U" M568 P1 R0 S0 ; Create a tool that prints 2 copies of the object using both carriages (copy mode) M563 P2 D0:1 H0:1 X0:3 S"X U Copy" M567 P2 E1:1 G10 L1 P2 X0 Y0 U0 ;bias M568 P2 R0 S0 ; Create a tool for mirror printing M563 P3 D0:1 H0:1 X0:3 S"X U Copy Mirror" M567 P3 E1:1 G10 L1 P3 X0 Y0 U0 M568 P3 R0 S0 ; Checking and creating a global variable for storing an active tool if !exists(global.active_tool) global active_tool = -1 ; Acting a variable, -1 means the lack of an active tool; Home A Axis ; Поднять суппорт каретки X M400 M42 P3 S1 ; Включить пневмоклапан для подъема суппорта X G4 P500 ; Ждать 500 мс M582 T2 ; Проверить триггер верхнего положения суппорта X ; Хоминг оси A G91 ; Относительные координаты G1 H2 X100 F5000 ; Отодвигаем каретку от щеки G1 H1 A-9999 F5000 ; Двигаем ось A в минус до срабатывания концевика G1 H2 A5 F1000 ; Двигаем ось A немного назад G1 H1 A-30 F300 ; Точный хоминг оси A ; Коррекция нуля (если нужно) G1 A160 F5000 ; Двигаем A в позицию 250 мм G92 A0 ; Устанавливаем ноль оси A G90 ; Возвращаемся к абсолютным координатам M400 ; Выключить пневмоклапан суппорта X M42 P3 S0 ; Выключить пневмоклапан M300 S500 P200 ; Звуковой сигнал -

@Stanislav said in PanelDue 7 loses macros after homing or moving rotary axes A/B:

Version of the firmware PanelDueFirmware-5.0i-7.0i.bin

If you look at the setup page on the PanelDue it should say the actual version.

-

Good afternoon, I looked at the current version Panel Due firmware 3.5.1

-

@Stanislav I updated your post with your config.g and homea.g, to make it easier to read.

Could you try with the debug logging turned off? Comment out the following lines in config.g, save, then restart:

M929 P"logs/eventlog.txt" S1 ; Log WARN level events to logs/eventlog.txt M929 P"logs/infolog.txt" S2 ; Log INFO level events to logs/infolog.txt M929 P"logs/debuglog.txt" S3 ; Log DEBUG level events to logs/debuglog.txtMy guess is that all the logging is taking up too much time to service requests for file lists from the PanelDue.

It's possible there's an SD card issue; please run the tests described here: https://docs.duet3d.com/en/User_manual/RepRapFirmware/SD_card#troubleshooting-sd-card-issues

Ian

-

Good afternoon!

Logov files have changed into the configuration, the result is the same. Additionally formatted the SD card with a utilitySD Memory Card Formatter. Storage ===

Free file entries: 19

SD card 0 detected, interface speed: 25.0MBytes/sec

SD card longest read time 2.4ms, write time 23.2ms, max retries 0.It is doubtful that the loss of macros and working files occurs only after the movement rotary axes, there is no problem with the linear axes.

-

undefined Phaedrux marked this topic as a question

undefined Phaedrux marked this topic as a question

-

Good afternoon,

I still have not solved the problem with the macros display in the PanelDue panel, how to solve this problem? -

I made another test, after homing when the macros ruined. Introduced the M84 command. The macros were restored. The problem is related to the drivers of additional axes A and B

-

Do you mean the shortcut buttons for the macros on the main display screen beside the tools?

Could you make a short video showing what you're seeing exactly?

-

Good afternoon!

I once again checked the problem and attach the video panel_due_1.mp4 -

Thank you for the video.

Can you do a test for me? Manually send the commands from your homea.g or homeb.g files one line at a time and check the macro tab in between to see if there is a specific line that is causing it.

I'm also curious if your PanelDue cable runs near the cables for the A and B motors? What kind of cable are you using for the PanelDue? How long, etc.

-

Good evening!

I showed a step -by -step check in the macros of the homing, the problem occurs at the step: G1 H1 A-9999 F5000. The connection cable is not shielded 4 residential, 1 meter long, laid separately. I also connected the panel with a flat short cable, but the macros also disappeared -

@Stanislav said in PanelDue 7 loses macros after homing or moving rotary axes A/B:

G1 H1 A-9999 F5000

Change the distance to home the axis to a little more than the axis length specified in M208, eg

G1 H1 A-210 F5000if the A axis has a maximum length of 200mm.

-9999 and below are a 'special' number usually reserved for probing and bed levelling, see https://docs.duet3d.com/User_manual/Reference/Gcodes#description-3If a "normal" Z parameter is given instead of -9999 or lower, then the bed is not probed, but instead that value is used as if the Z probe had triggered at that height.

This may be a bug, but if you could test this first it would be helpful.

Ian

-

I found the reason for the problem. Perhaps you explain its nature. The steps motors of the axes A and B had 6 wires 4 of which were sweaty to the controller. After replacing the engines with 4 wired problems did not appear.

-

undefined T3P3Tony has marked this topic as solved

undefined T3P3Tony has marked this topic as solved