6XD vs 1XD performance

-

Hi. I'm looking to get some insight in what performance limitations I may get when daisy-chaining four 1xd boards compared to using a 6XD board.

First: I believe the documentation on the 1XD boards i a bit outdated. The maximum step rates seem to be measurements on firmware version 3.2, but reading the step rate post in this forum and the firmware changelog it seems this was improved in version 3.3 (new rates not measured?). This may also have changed again due to input shaping? Anyone have a clue on what step rates I could expect today, using 4 boards on the CAN bus?

Also regarding input shaping the documentation has conflicting information, one place is saying that it will not be implemented and therefore 1XD boards should not be used to drive primary axis, and one place saying that it will be implemented. Looking at the firmware changelog it seems like it is already implemented? What is the actual status on this? And if I choose not to configure input shaping, does that improve step rates?

So the documentation on the 1XD needs some updating. But let me get to my actual core questions.

First: Is the 1XD a viable option for the main axis of a high performance machine, if I can accept step rates of (worst case) around 40kHz? The documentation says no but again that seems to be based on outdated information.

Second: The 6xd uses single ended signaling and not differential. If I want to combine this with integrated servos (driver mounted on the motor) Could I reliably send step-dir signals up to 200kHz over 4 meter long cables in parallel with power-feed cables? I could see this being a problem but electronics is not my field.

Third: are there other potential issues besides the step-rate and signaling to consider? I don't know how motion control is implemented on external boards, does axis synchronisation suffer due to latency in the CAN bus or is there some smart scheduling being done with synchronised clocks?The background: I have a CNC router currently driven by the 6mbhc. Ball screws 10mm pitch for x and y, 4mm pitch for Z. Double Y axis motors (så 4 motors in total). I use this CNC for production and I want more speed, power and reliability than I can get out of open loop steppers. Ideally I would like to go all in and add 3000rpm servos on all axis and turn the rapid feed and acceleration up so high that I'd need to bolt the machine to the floor. Cycle-time is money! To get the very best performance clearly the 6xd is the way to go. But I have limited to time spend on this conversion, and going this route would mean building an entirely new control box and redoing all the wiring before I can even start configuring the new system. Then I need to so servo tuning after that. I'm also concerned about signal integrity this way. I was planning to use integrated servos with the driver mounted on the motor, meaning the step-direction signals may need to be routed up to 4 meters in parallel with power feed cables for the other motors and the spindle. On the 6xd these signals are single-ended and not differential. I could see this being a problem if I have pulse rates up to 200kHz, but I am no expert on electronics.

The other option is adding 1xd boards to my 6hc motherboard. Given the limited step rates of 1xd servos would make no sense, so I would go with closed loop steppers. This will not improve feeds by much but it should improve acceleration and reliability. You answers will help me decide if I should settle for this option.

Thanks in advance. And sorry for the long post, part of it is because the documentation is a bit contradicting.

-

undefined Phaedrux marked this topic as a question

undefined Phaedrux marked this topic as a question

-

You are correct, the 1XD documentation is somewhat outdated. We did improve the step rates in version 3.3, and we did implement input shaping on it in firmware 3.5. However the input shaping implementation is completely different in 3.6. It may turn out that we need to disable input shaping on the 1XD in 3.6.

We expect to publish figures for 1XD step rates with 3.5.4 and 3.6beta firmware within the next week.

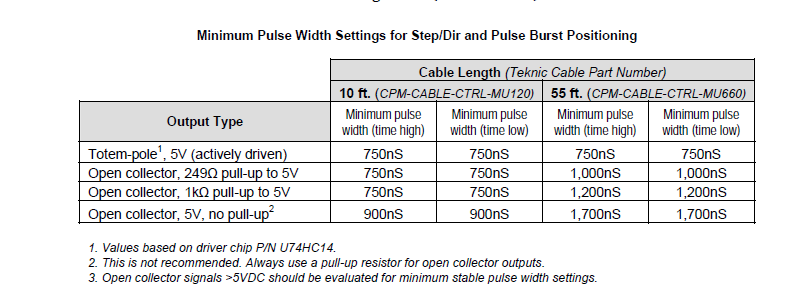

Regarding the 6XD outputs, they are indeed single-ended. However the version 1.02 6XD boards have active pullup to better support high step rates, as recommended by Clearpath in the manual for their drivers. When using earlier version 6XD boards, adding pullup resistors to the step and direction outputs helps achieve high step rates.

Here is an extract from the ClearPath manual. It indicates that using a version 1.02 6XD the limit is around 1e9/(750+750) which is more than 600k steps/sec. The same step rate is available using 1K pullup resistors if the cable length is 10ft but it drops to 400k steps/sec with cable length 55ft (note, these figures are when using the specified cable types).

We made provision for adding a daughter board to the 6XD to convert the single-ended outputs to differential, however to date we have not developed this daughter board.

HTH David

-

Thanks for the answers! I was leaning towards the JMC integrated servos rather than clearpath, these are about half the price and accept a maximum steprate of 200khz. Although clearpath is also an option I was considering, but using them would be the no-compromise route so then I would lean even more towards 6xd.

Either way I'm mostly limited in the time I can spend putting together new hardware, and going 1xd is a quicker fix. Like I said I just need to understand what performance I can expect so it doesnt end in dissappointment. If new measurement are posted in a week or two I'll wait for them to decide. Input shaping is not a dealbreaker for me since I have a very rigid machine.

Again big thanks!

-

Any progress on measuring and publishing new step rates for the 1XD? I've been regularly checking the 1XD docs, the "Duet maximum achievable step rates" post, and the google docs spreadsheet in said post but I have not seen any updated figures as of yet.