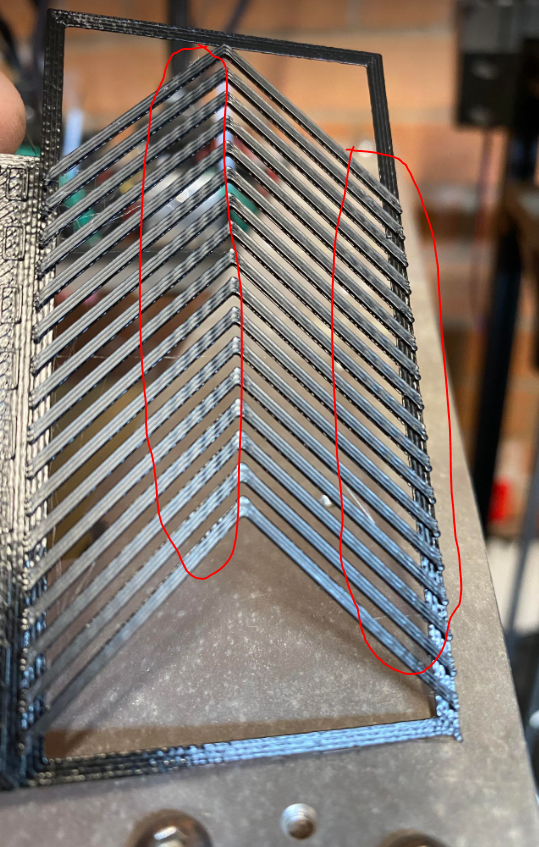

Slight ripple at start and end of lines

-

Im getting some odd ripples at the start and the ends of the lines.

I noticed this while doing a pressure advance calibration test. It exists while adjusting the values but also if I disable it,

I thought maybe this could be something to do with acceleration and jerk?

Im on an e3d tool changer and im running a hemera XS with revo 0.4mm brass nozzle.

To me it looks like its happening on acceleration but not deceleration as the ripple doesnt seem to be happening at the end of the lines.

This is my config:

M584 X0 Y1 Z2 C7 E3:4:5:6 ; Apply custom drive mapping

M208 X-35:328.5 Y-49:243 Z0:300 C-45:360 ; Set axis maxima & minima

M92 X100 Y100 Z1600 C91.022 E394:394:394:394 ; Set steps per mm assuming x16 microstepping

M350 E16:16:16:16 I1 ; Configure microstepping with interpolation

M350 C16 I10 ; Configure microstepping without interpolation

M350 X16 Y16 Z16 I1 ; Configure microstepping with interpolation

M566 X300 Y300 Z10 C2 E200:200:200:200 ; Set maximum instantaneous speed changes (mm/min)

M203 X35000 Y35000 Z600 C5000 E5000:5000:5000:5000 ; Set maximum speeds (mm/min)

M201 X2500 Y2500 Z100 C500 E4000:4000:4000:4000 ; Set accelerations (mm/s^2)

M906 X1800 Y1800 Z1330 I30 ; Idle motion motors to 30%

M906 E1200:900:900:900 C500 I10 ; Idle extruder motors to 10%Ive got input shaper set to none for this test and im printing at 100mm/s

Any ideas what might be causing this? Ive tried changing accell from 2500 to 4500 and the ripples all show in the same place.

Belts are tight too. -

@Festivejelly I’d guess this either exactly what input shaping is for, ie frame ringing, as the nozzle accelerates, or possibly an extruder drive issue such as a loose gear or cogging of the gears. As it goes away, more likely ringing, though.

Ian

-

@Festivejelly That's called ringing and is the main reason for using input shaper.

You can use a simple formula and calculate your resonance frequency from- measure the distance between the ripples

- calculate frequency based on printspeed

Sorry, I can't remember the formula from the back of my head. It was mentioned somewhere in the Duet Wiki in the input shaping chapter.

The other option is to mount an accelerometer to your tool head and install the IS-module in DWC. -

I see, but id expect this at the end of acceleration if it was ringing. Not the start.

-

@Festivejelly It's usually the deceleration from another direction that triggers the ringing.

-

@gloomyandy Not the case here as it retracts and Zhops to the beginning of each line. I suspect it to be an issue with the hemera XS. I havent used this printer in like a year and put the new hemera XS on it to reduce the weight. Ill try some of the other tool heads to see if they have the same issues.

It happens even at very slow speed.