Duet 2 Wifi - Heater Fault - Sensor Short - 2000c

-

Hey everyone.

I am having some problems on one of 5 printers with the exact same setup.

We are having very long cables to allow us to put our DUET outside our chamber, this causes some problems on one of our setups.

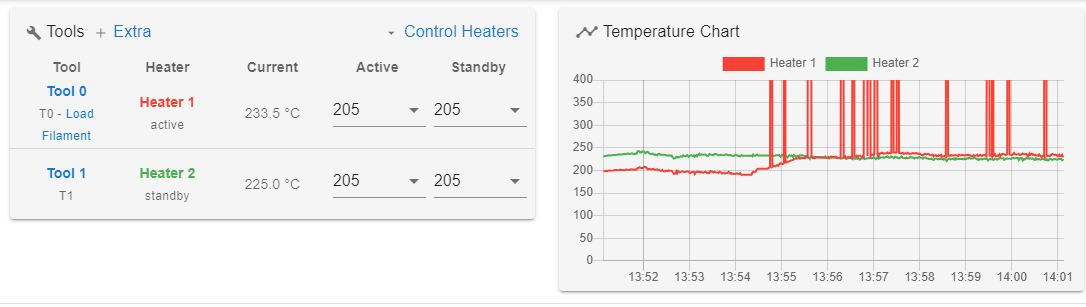

Problem 1 - Small flickering of temperatures makes it impossible to do a proper PID tune:

Problem 2 - IF heating the chamber - I am getting flicks to 2000c almost every 10 seconds which causes the firmware to turn the heater into fault state:

I am wondering if we should connect the PT100's with more wires, or with a small resistance in between it? Right now we have shielded cables for the PT 100's.

Can i measure the resistasnce somehow in the PT100 to check if there is any fault?It is very clear when heating the chamber - my faults come more often than if it is not heated. However I am getting the errors no matter what.

Thank you in advance,

Mike

-

I switched out the PT100 daughterboard and now the 2000c sensorshort is gone.

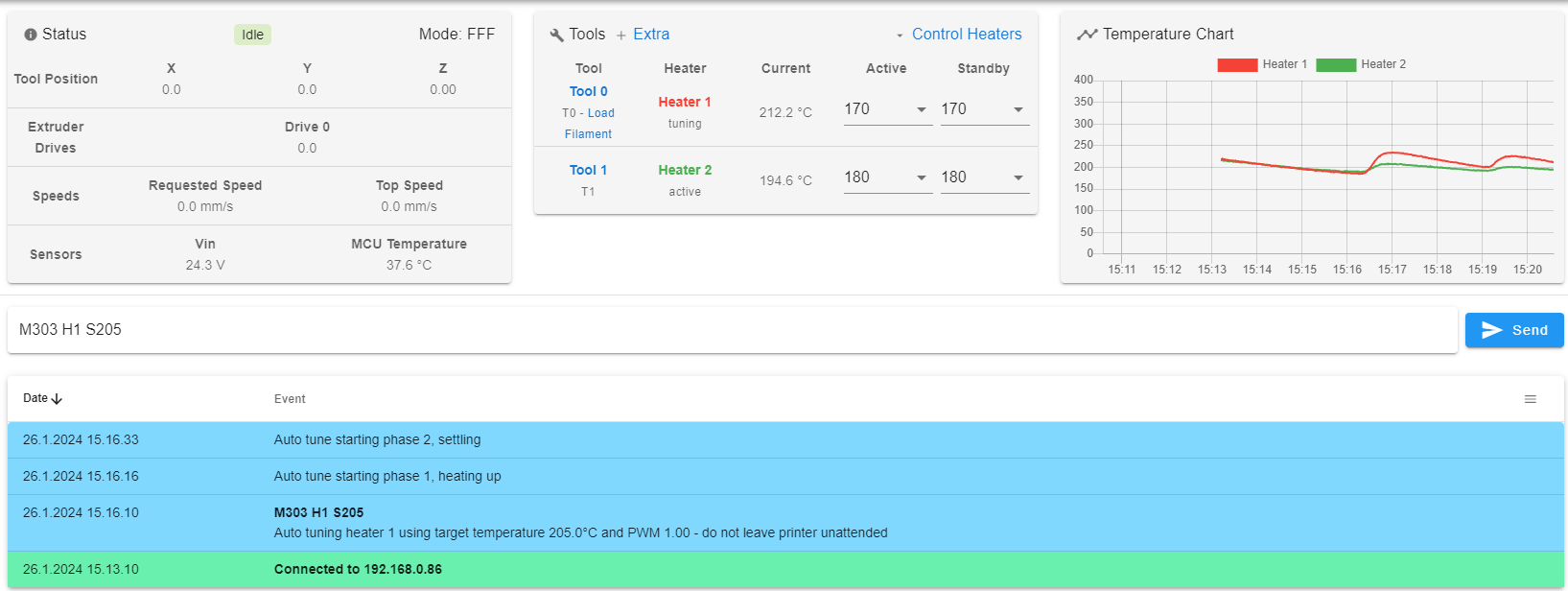

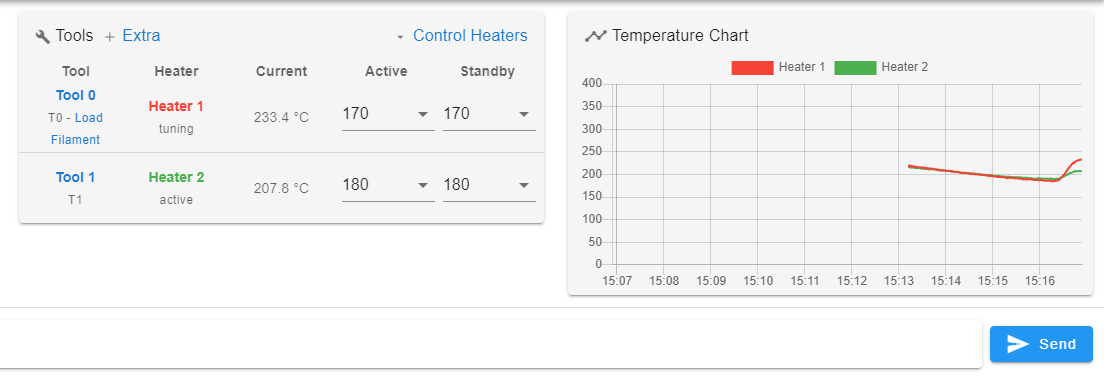

However when tuning Heater 1, I am getting quite a large overshoot.

This hotend is a Dyze Typhoon with 2 heaters - When FLOW increases fast my PID tune becomes worthless.

Would it be better to tune in this manually?

I do NOT have any fans connected that will turn on or off when doing the Autotune.

-

@mikep91 Maybe heater feedforward would help? https://docs.duet3d.com/User_manual/Reference/Gcodes#m309-set-or-report-heater-feedforward

Wiki: https://docs.duet3d.com/en/User_manual/Connecting_hardware/Heaters_tuning#heater-feedforwardFor the overshoot, see https://docs.duet3d.com/en/User_manual/Connecting_hardware/Heaters_tuning#manual-adjustments-to-the-heater-model-parameters

Ian

-

Hi droftarts.

Thank yoo - I think i will need to do some heater feedforward when time is right. For now I will need to find the reason for the flickering temp values and so I can perform a proper PID tune.

Are there anywhere i can measure resistance on the PT100's to see if they are having the correct resistance or if i should put in a resistance of some sort?

We are running quite long cables for the PT100's but they are shielded.

-

@mikep91 said in Duet 2 Wifi - Heater Fault - Sensor Short - 2000c:

We are running quite long cables for the PT100's but they are shielded.

Switch to a 4 wire configuration if possible.

-

@mikep91 said in Duet 2 Wifi - Heater Fault - Sensor Short - 2000c:

We are running quite long cables for the PT100's but they are shielded.

Note that shielding on it's own may not help. Cable shielding only works if one end of the shielding is grounded. Grounding both ends can cause the shielding to transmit signals, and grounding neither end can cause reflections from the cable itself.

As for 2-wire vs 4-wire, see https://docs.duet3d.com/en/User_manual/Connecting_hardware/Temperature_connecting_PT100#wiring-the-pt100-temperature-sensor

2-wire connections have the advantage of wiring simplicity. 4-wire connections have the advantage of greater accuracy; the extra wires compensate for the resistance drop in the wires, making readings more accurate. 4-wire does not improve resistance to interference; better approaches to reduce noise include twisted wiring, isolation from noise sources, shielded wiring, better grounding of components etc.

Ian