Change Print Speed DuringPrint

-

@Dizzwold no, changes to speed , acceleration and so on are applied to the next move that goes into the queue. So it’ll take a few moves to change, but then will take effect.

Ian

-

@droftarts Hi Ian

So if I enter M203 F3000, after a few seconds - minuets, it should go no faster than 50mm/s.

With entering the above in the DWC, is this just a temporary setting or will it change the config.g?

Thank you.

Dizzwold.

-

Maybe I don't understand but I would just go to the 'status' panel in DWC and use the speed slider to whatever slower setting seems appropriate. It only applies to the current print job.

Oh, next I would isolate whatever the printer sits on from any outside wall (or floor) because a printer should not be heard in the next room ..... -

@Dizzwold said in Change Print Speed DuringPrint:

@droftarts Hi Ian

So if I enter M203 F3000, after a few seconds - minuets, it should go no faster than 50mm/s.

With entering the above in the DWC, is this just a temporary setting or will it change the config.g?

Thank you.

Dizzwold.

It doesn't change config g. It will persist until it is overwritten by another value. If you cycle power, that will load config.g again, which in turn will then overwrite the value you previously entered.

-

@jens55,

Thanks for that, I'll give the Speed Slider a go next time around.Lol, Isolation.

I live in a 1st floor maisonette which is a block with 4 dwellings. My printer is in a cupboard which is basically above the stairs into my flat.

The diagonal void beneath the printer is filled with acoustic Rockwool;

This whole void beneath the timber is filled with Rockwool, but to demonstrate the 'Diagonal void above my stairs'.

On top of the resilient tape is 18mm MDF.

On top of the MDF is a sheet of Techsound 100 MLV.

On top of the MLV is 50mm of reconstituted 9lb foam, then 50mm of Very Firm Closed Cell upholstery foam.

Then finally the printer.The walls have Techsound 100 MLV adhered to 12mm acoustic plasterboard which is hung on metal resilient strips and the void again filled with acoustic Rockwool.

On top of this I then have 40mm convoluted acoustic foam and 50mm flat acoustic foam on the cupboard door.

Finally I have acoustic foam on the cupboard ceiling.

My neighbour downstairs obviously has a problem with over sensitive hearing or he is some-kind of superhero.

My other neighbour adjacent to me upstairs is elderly and in poor health. I've recently found that she is bed-bound and has one of those hospital air mattresses to prevent bedsores. I think it's this accidentality being pushed against the wall and what can be heard is the small compressor pumping segments up.

I actually paused the printer for a while to try to find the noise as it continued. Every 4mins buzzing for about 5 seconds.

Some ones Egg Timer maybe?Not my printer after all that. Oh, the joys of 3d printing in a flat.

Anyway I've learnt some things from the above, other than telling my neighbours to 'go do one'.

Thank you for your help.

Dizzwold.

-

@Dizzwold, holy crap, that is a LOT of sound isolation! As you noted though, if there is direct contact between the printer frame (ie feet) and any sort of part of the house, all the free air sound insulation in the world isn't going to stop the sound that travels through the building itself.

I agree that the hospital air mattress is very likely the culprit but it's amazing how the vibration can travel. I have a massive work bench that I can climb on top of and tap-dance on top of. It is attached to the wall and supported on the concrete floor below it and I wouldn't be surprised if it has a mass well north of 500 kg's and the damn printer vibrations can clearly be felt throughout this work bench (I figured it would be usable as an earthquake shelter). It blew my mind when I found this out!

People have figured out that putting a printer on a heavy concrete paver can do wonders for the surface finish of prints and a thin layer fo heavy foam between the paver and whatever it sits on can do a lot to reduce sound/vibration through the support/table.

While I realize that 'to go do one' was hyperbole, never actually say that to a neighbour unless you want to generate serious bad blood.That is a LOT of insulation! How do you keep the environment cool when printing something like PLA?

-

Lol.

@jens55 said in Change Print Speed During Print:

How do you keep the environment cool when printing something like PLA?

There lies another problem, yet to be calibrated. I have an 4" 24v inline extraction fan used in boats connected to the Duet. I have a thermistor buried in the false ceiling also connected to the duet.

The fan is currently triggered at 42˚C, but from the little time I've had it installed (about a fortnight), I've so far only seen the maximum temperature of 40˚C while printing PLA. It seems to keep at an average of around 37-38˚C, but 40˚C when the print head is directly below the thermistor.

Sadly it turns out that this fan is quite noisy and can't be used with PWM as it only get louder (I've tried).

link textI've had quite a few problems with a ripple effect, which I guess is due to the temperature within the chamber/enclosure/cupboard.

My cheeky neighbour has recently said if I "was to start making money from this (3d printing), he wants a cut of the profits.

Well when he next makes any demanding statements like that he'll be advised he can have 5% of the profits after he's paid myself 5% of my setup costs and model designing labour.

So far the soundproofing materials have cost me £800 alone.Out of curiosity, where do deleted job files go. I'd like to check previous print settings compared the my last print.

Dizzwold.

-

@Dizzwold said in Change Print Speed DuringPrint:

Out of curiosity, where do deleted job files go. I'd like to check previous print settings compared the my last print.

Big round bit bucket in the sky ????

I have no idea what happened but it doesn't seem to be related to heat. Try printing while the door to your enclosure is open (while your neighbour is away).

40C enclosure temperature is pretty darn high for PLA. I used PLA for a component in my enclosed printer and it pretzeled on me. I ended up reprinting it in ABS .... but I was seriously surprised that a PLA part would turn soft enough to deform at only 40C. Since glass transition temp is around 60-65C, I was expecting to be ok to at least 50C. -

undefined Dizzwold referenced this topic

undefined Dizzwold referenced this topic

-

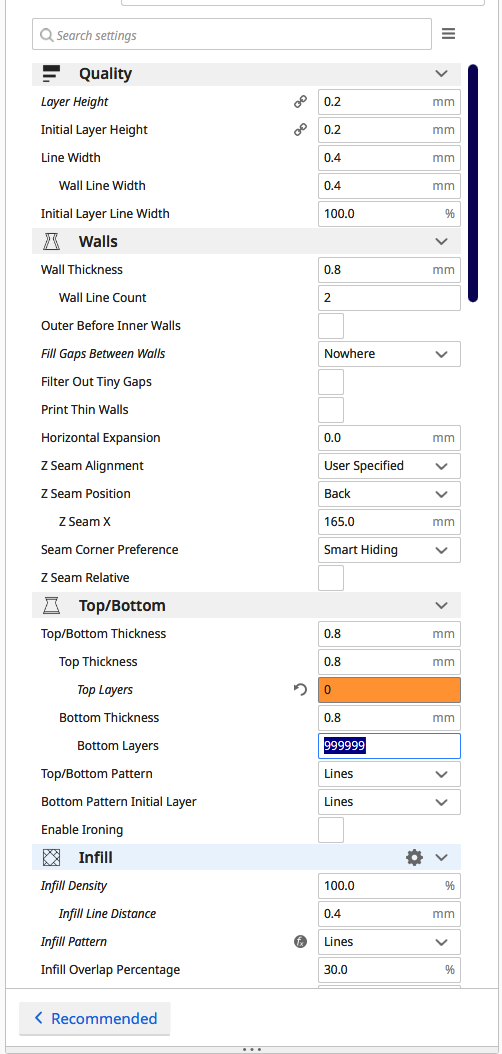

Just spotted this in my Cura settings where it has set the Bottom Layers to 999999, and wonder if this is the problem causing the roughness shown above?

-

That sure could do it. It wouldn't be using any of your other settings, only the bottom layer settings all the way up.