Using the keyboard to manually drive the printer?

-

@Jered

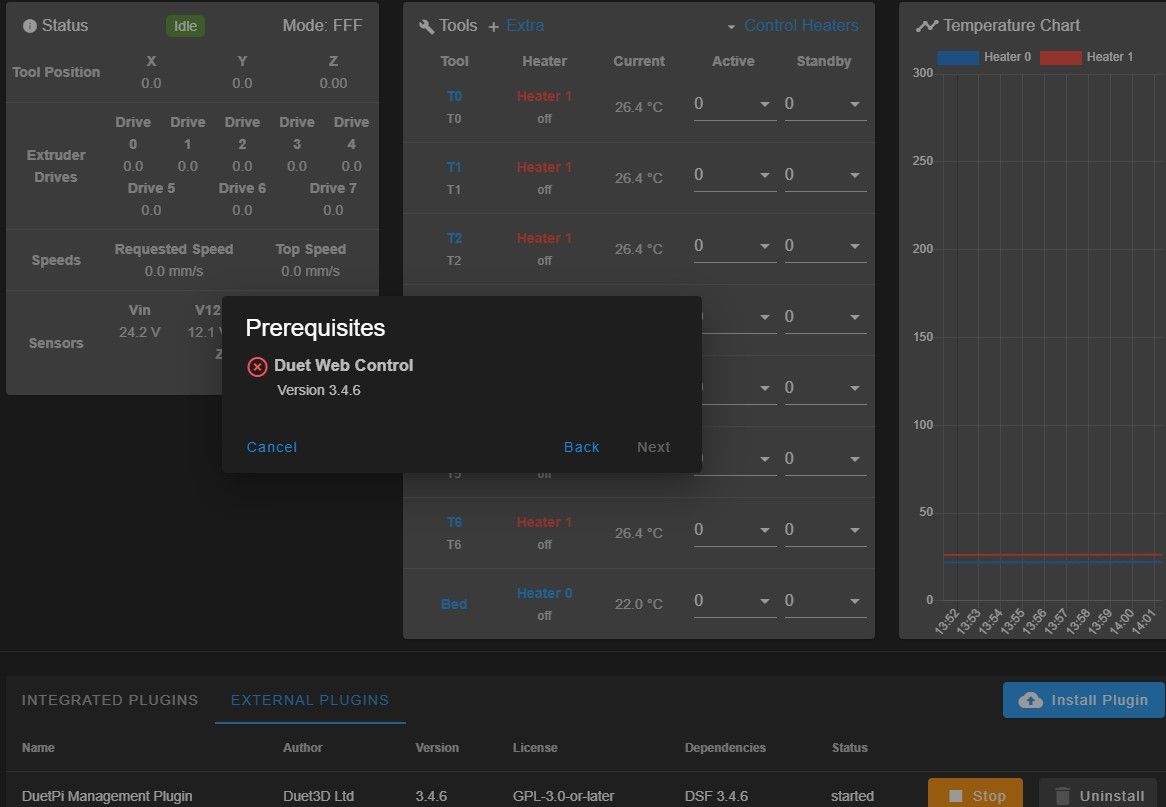

I just noticed that I have the latest Duet Web Control 3.4.6 -

@Jered

So, I am guessing this is not compatible with DWC 3.4.6. I have attached a pic of what happens when I try to install it.

-

@Jered

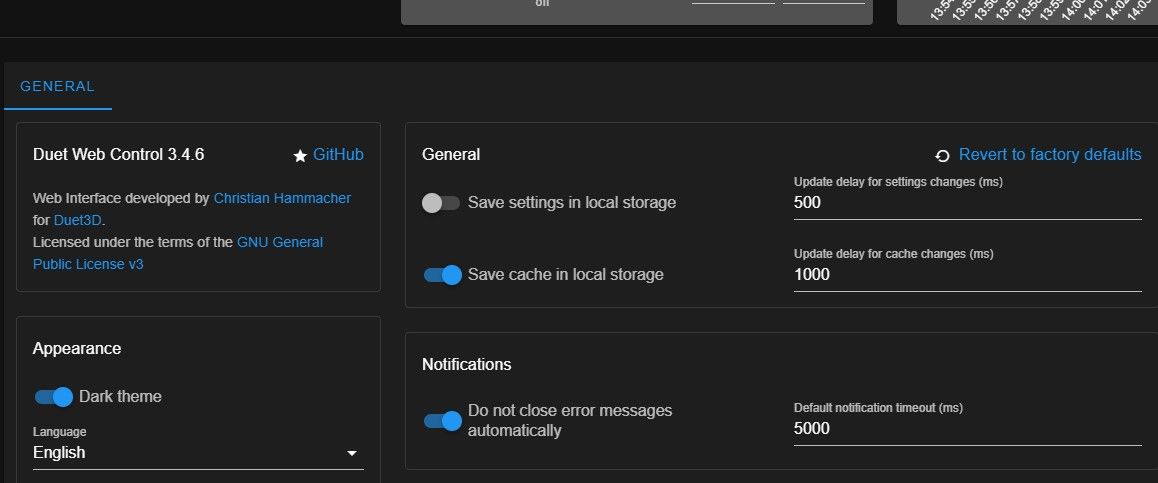

Here is a pic of my current version.

-

@Sindarius said in Using the keyboard to manually drive the printer?:

I do not have a 3.4 version posted but will look into getting one up.

@Jered It looks like you'd either have to wait for a 3.4 version, try out the 3.5RC1 test build, or roll back to 3.3.

-

@Jered I put together a release for 3.4 that should work/install for you.

https://github.com/Sindarius/DWC_GamepadJogger_Plugin/releases/tag/1.1-3.4.0

-

@Sindarius

Thanks!!This did install! I will play around with it today!

-

@Jered

I guess this works, but was hoping for a continuous jog mode. Seems to only support incremental jogging, set by the chosen increments at the top of the game pad page.For this reason, there is no way i would use this controller for a cnc. Not enough support yet.

I have been using large cnc's for years. When positioning them for certain jobs, you need a pendant, keyboard or handheld jog wheel that will reach where you need to go with the cnc. You can't run back to the display every time and jog a bit more, then a bit more, and a bit more.... ect. This would take forever and is not convenient for anyone.

In the future, I would like to build a cnc using this controller, but it's just not there yet.

-

Have you seen this? https://forum.duet3d.com/topic/33892/cnc-pendant-wiring-schematic

-

@Phaedrux

I will have a look at this, but the keyboard is cheaper and easier. Have you guys ever looked at Mach4 (Newfangled Solutions) and the way that they handle code and their software solutions? They are kind of the standard for consumer grade cnc controller software. It would be nice if you guys could steal some of their business by integrating some of those features they offer into your DWC. Real time gcode viewing and manually manipulating the machine while the DRO's update in real time as well are some major features that are needed.Being able to see the gcode scrolling by as the machine is milling is very handy when there is a problem. If a problem occurs, I can pause the machine, look at the line of code it is on, correct the problem, put the machine at the correct line of gcode and hit go again. This way I don't have to start over or scrap something that could be saved.

You guys have a very good product! I think it is under utilized do to a few missing elements that could be added (for the cnc world that is).

I use your product to build incredible industrial 3d printers that have 13 stepper on one machine! I also build industrial cnc's for people in all kinds of industries. Unfortunately, I have to use a different software/controller package to do it. I would like to switch to using one controller for all applications.

I should have minored in programing so I could help out with this. I am a EE, and can program PLC's, but anything else is out of my reach.

Anyways, your product is amazing for 3D printers. It's the only one I use! I hope someday it will be the best all around controller!!

Thanks for your help!

Below is my latest project, which is converting an Ender 5 to a multi material Duet machine.

-

Thanks for the feedback on CNC usage. It's something we're always trying to improve.