POLAR PRINTER

-

Good morning everybody. I'm making a polar printer, where X is angular mov and Y,Z are lineal. Is not the turntable, its "turnbody" machine.

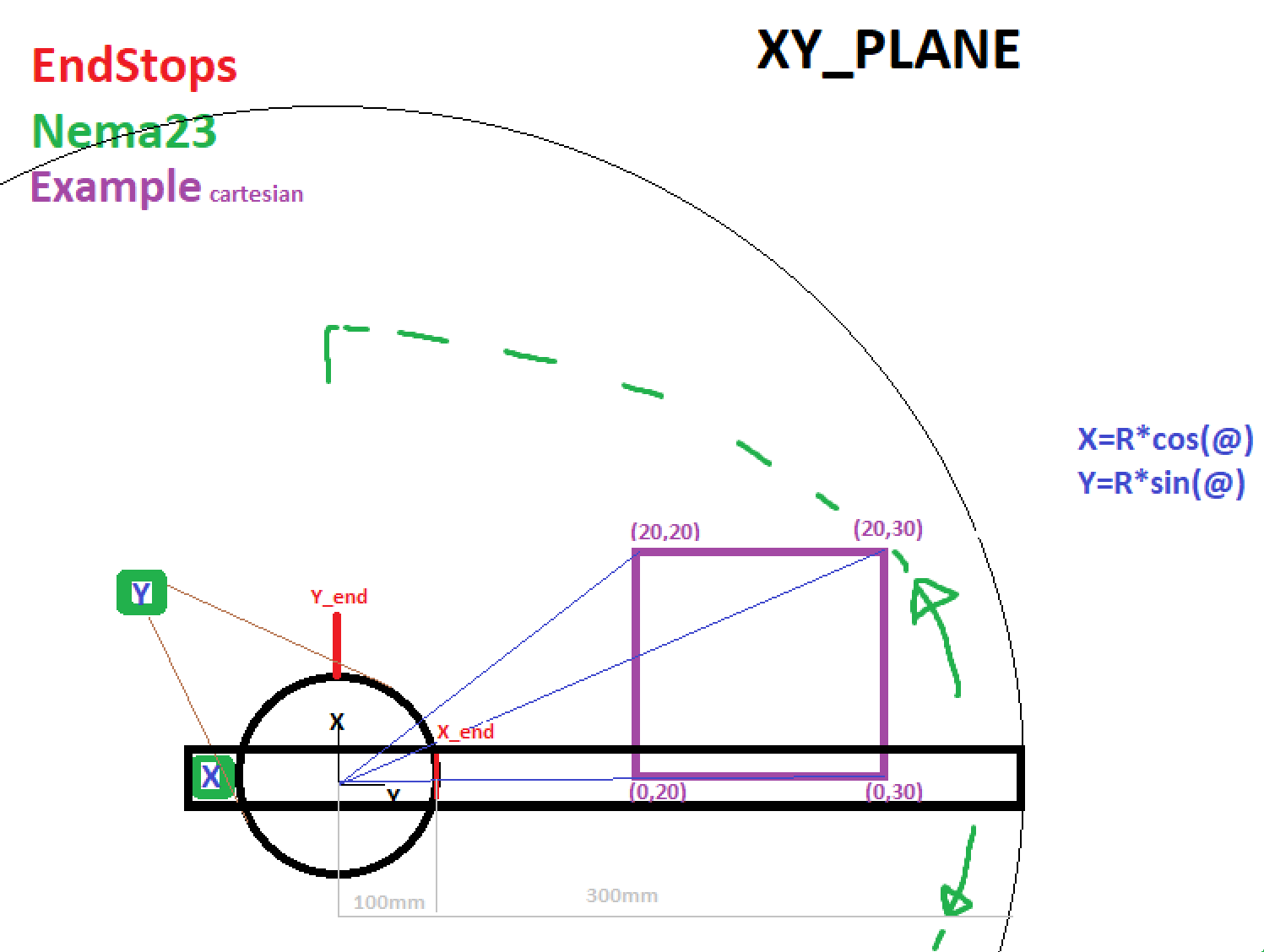

Looking for a Z=0 plane, we have some type of a "donut" print zone. (Ej: Dint=10cm; Dext=40cm;) I think that the coordinates origin of cartesian / polar sistem are the center of the machine.

In config I have M669 K7 .... but I dont khnow to make correct configuration becouse I have different design.

-

-

@dc42, yes I did! I'm sorry for my ignorance.

I have some accurate questions about it:- How you can see, my Rmax=400mm and Rmin=100mm from the center of rotation. But at 100mm from this center, I have "X_end" => H100.

So, It's correct M669 K7 R100:400 H100?

Or It should to be M669 K7 R0:300 H100? - If I have TB6600 drivers configurated by micro-stepping, I understand that I no need Snnn and Tnnn (segmentation), true?

- In a sample, you don't have M208 for Z axis. I think that its necesary here.

- About the interface, I don't khnow softwares that can manipulate "donut_print_zone", should I send Gcodes manually (in cartesian coordinates)?

I hope I'm not disturbing you so much... I really need to get it for my university project. I've been with this for a long unsuccessfully.

When I finish it, I would like to reward you for your help!!!! - How you can see, my Rmax=400mm and Rmin=100mm from the center of rotation. But at 100mm from this center, I have "X_end" => H100.

-

@xXJRUSHMANXx said in POLAR PRINTER:

So, It's correct M669 K7 R100:400 H100?

That's correct if your radial homing switch triggers at radius 100mm.

@xXJRUSHMANXx said in POLAR PRINTER:

If I have TB6600 drivers configurated by micro-stepping, I understand that I no need Snnn and Tnnn (segmentation), true?

Segmentation is always used when polar kinematics is selected. You can omit the S and T parameters to use the default, or choose them yourself.

In a sample, you don't have M208 for Z axis. I think that its necesary here.

Yes, you should use M208 to configure the Z axis limits.

About the interface, I don't khnow softwares that can manipulate "donut_print_zone", should I send Gcodes manually (in cartesian coordinates)?

For normal prints that don't have a large hole in the centre on all layers, you will need to offset the print so that e.g. all X coordinates are at least +100mm. You may be able to configure this in your slicer. Alternatively, use G10 with parameter L2 to configure a workplace offset, and put this in your slicer start GCode.

-

undefined oliof referenced this topic

undefined oliof referenced this topic