X axis Tool head Offsets

-

I use duet wifi version 1.02

Firmware 3.4.5

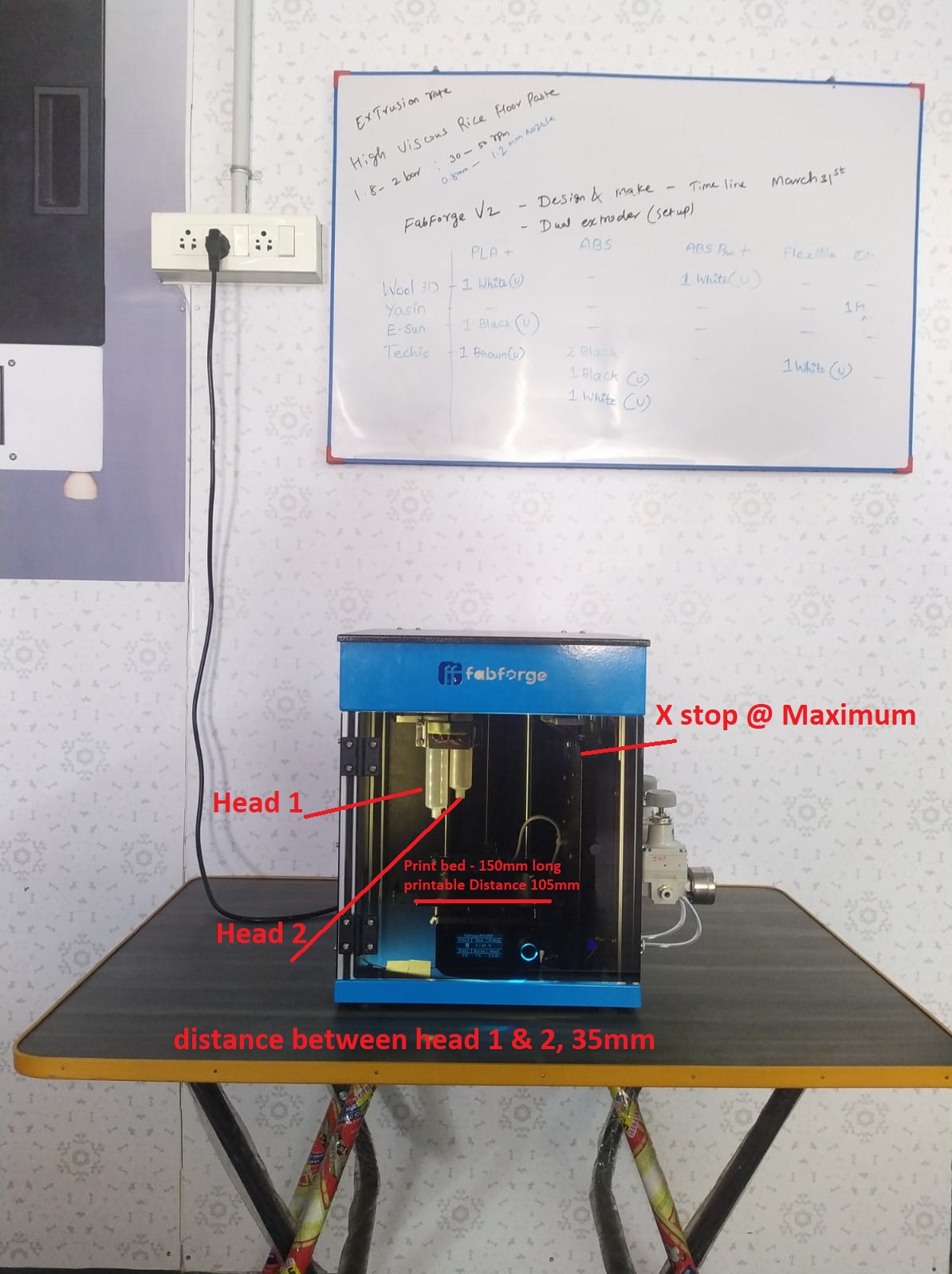

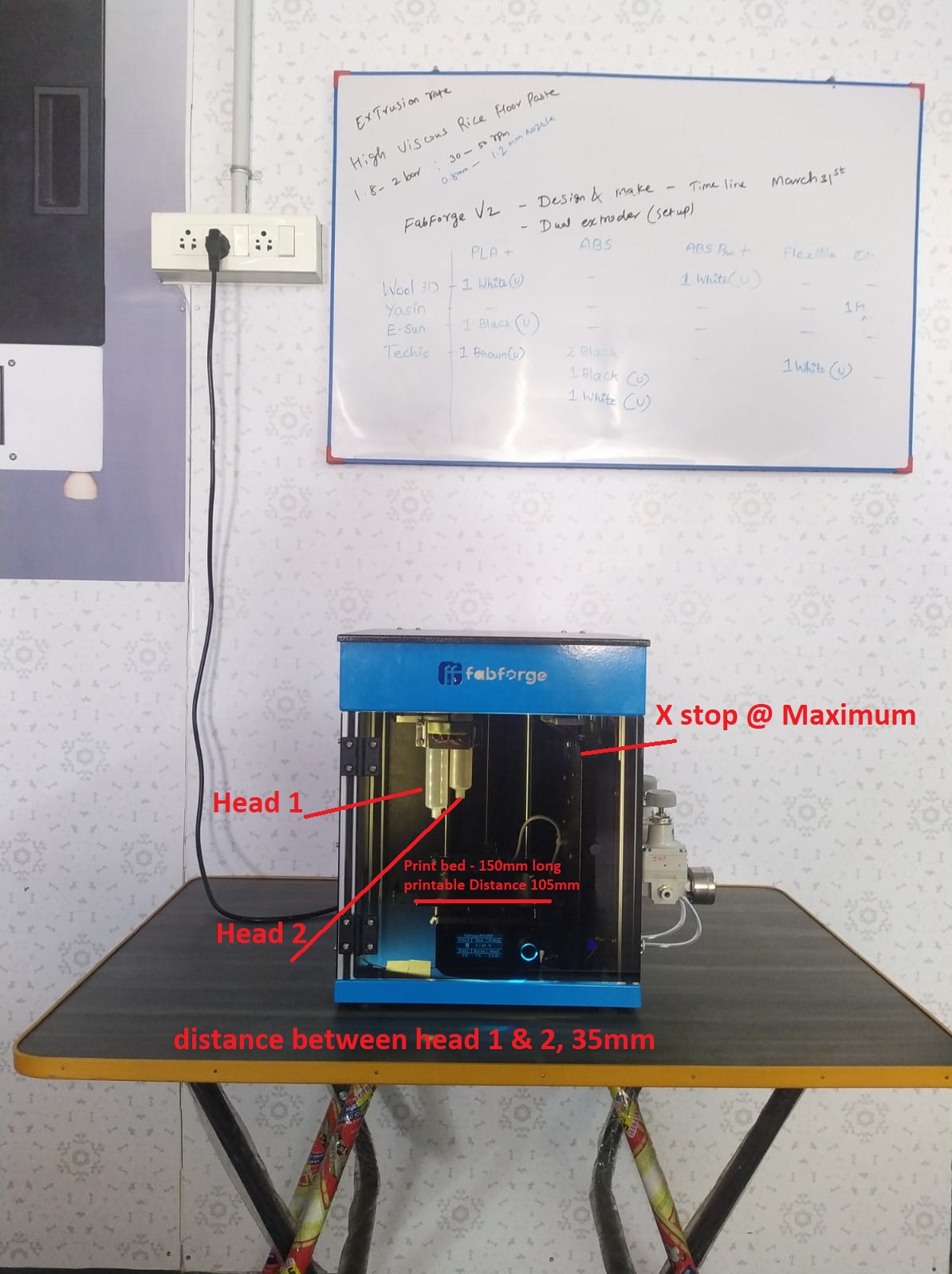

In my machine x stop is at maximum, my first head is about 50mm when its on endstop position, 1st & 2 Tool distance is 35mm , how should i make tool offset distance?

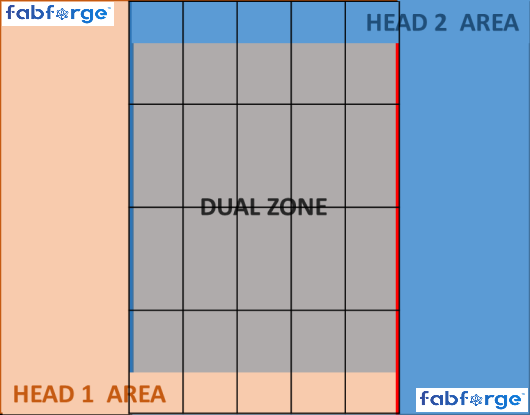

My printable area for single head is x105,y110,z100 each, Dual print area x70,y110,z100.

and in slicer what should be the bed dimension,

Homex.g

G91 ; relative positioning

G1 H1 Y-110 F1800 ; move quickly to Y axis endstop and stop there (first pass)

G1 Y5 F6000 ; go back a few mm

G1 H1 Y-115 F360 ; move slowly to Y axis endstop once more (second pass)

G1 H1 X105 F1800 ; move quickly to X axis endstop and stop there (first pass)

G1 X-5 F6000 ; go back a few mm

G1 H1 X105 F360 ; move slowly to X axis endstop once more (second pass)

G1 X-105 F1800

G92 X0

G90 ; absolute positioningConfig.g

; Axis Limits

M208 X0 Y0 Z0 S1 ; set axis minima

M208 X105 Y110 Z135 S0 ; set axis maxima; Endstops

M574 X2 S1 P"xstop" ; configure switch-type (e.g. microswitch) endstop for high end on X via pin xstop

M574 Y1 S1 P"ystop" ; configure switch-type (e.g. microswitch) endstop for low end on Y via pin ystop

M574 Z2 S1 P"zstop" ; configure switch-type (e.g. microswitch) endstop for high end on Z via pin zstop; Tools

M563 P0 S"Head 1" D0 H0 F0 ; define tool 0

G10 P0 X0 Y0 Z0 ; set tool 0 axis offsets

G10 P0 R0 S0 ; set initial tool 0 active and standby temperatures to 0C

M563 P1 S"Head 2" D1 H0 F0 ; define tool 1

G10 P1 X35 Y0 Z0 ; set tool 1 axis offsets

G10 P1 R0 S0 ; set initial tool 1 active and standby temperatures to 0C

-

@adhanabal said in X axis Tool head Offsets:

I use duet wifi version 1.02

Firmware 3.4.5

In my machine x stop is at maximum, my first head is about 50mm when its on endstop position, 1st & 2 Tool distance is 35mm , how should i make tool offset distance?

My printable area for single head is x105,y110,z100 each, Dual print area x70,y110,z100.

and in slicer what should be the bed dimension,

Homex.g

G91 ; relative positioning

G1 H1 Y-110 F1800 ; move quickly to Y axis endstop and stop there (first pass)

G1 Y5 F6000 ; go back a few mm

G1 H1 Y-115 F360 ; move slowly to Y axis endstop once more (second pass)

G1 H1 X105 F1800 ; move quickly to X axis endstop and stop there (first pass)

G1 X-5 F6000 ; go back a few mm

G1 H1 X105 F360 ; move slowly to X axis endstop once more (second pass)

G1 X-105 F1800

G92 X0

G90 ; absolute positioningConfig.g

; Axis Limits

M208 X0 Y0 Z0 S1 ; set axis minima

M208 X105 Y110 Z135 S0 ; set axis maxima; Endstops

M574 X2 S1 P"xstop" ; configure switch-type (e.g. microswitch) endstop for high end on X via pin xstop

M574 Y1 S1 P"ystop" ; configure switch-type (e.g. microswitch) endstop for low end on Y via pin ystop

M574 Z2 S1 P"zstop" ; configure switch-type (e.g. microswitch) endstop for high end on Z via pin zstop; Tools

M563 P0 S"Head 1" D0 H0 F0 ; define tool 0

G10 P0 X0 Y0 Z0 ; set tool 0 axis offsets

G10 P0 R0 S0 ; set initial tool 0 active and standby temperatures to 0C

M563 P1 S"Head 2" D1 H0 F0 ; define tool 1

G10 P1 X35 Y0 Z0 ; set tool 1 axis offsets

G10 P1 R0 S0 ; set initial tool 1 active and standby temperatures to 0C

-

undefined Phaedrux moved this topic from Firmware installation

undefined Phaedrux moved this topic from Firmware installation

-

I'm not totally clear what question you have.

@adhanabal said in X axis Tool head Offsets:

G1 H1 X105 F360 ; move slowly to X axis endstop once more (second pass)

G1 X-105 F1800

G92 X0This is confusing to me. If the maxima in M208 is correct, you shouldn't need the move to the minimum and setting X0 there. What effect is that having for you?

The slicer bed dimension should be your full bed area. The slicer will also likely have the option to define the offset of the second tool.

Is the physical travel limited to just the bed area, or can it go off the edge?

-

@Phaedrux hi thank you, i have actually fixed the issue

-

@adhanabal That's great. How did you resolve it?

-

@Phaedrux I adjusted bed size in slicer and mentioned tool offset

and created custom bed image to avoid placing the object in wrong position in the bed for tool heads.

-

undefined Phaedrux marked this topic as a question

undefined Phaedrux marked this topic as a question

-

undefined Phaedrux has marked this topic as solved

undefined Phaedrux has marked this topic as solved