Duet Wifi - Accel

-

Your tool definition is missing an extruder drive assignment.

You must add

D0like this to your tool definition.M563 P1 S"tool1" H1 F0 D0This assigns the first extruder drive to the tool.

It would be easiest if you copy and pasted the text of your config.g here so we can see the whole thing at once.

You can also send M98 P"config.g" in the gcode console and you may catch some error messages.

-

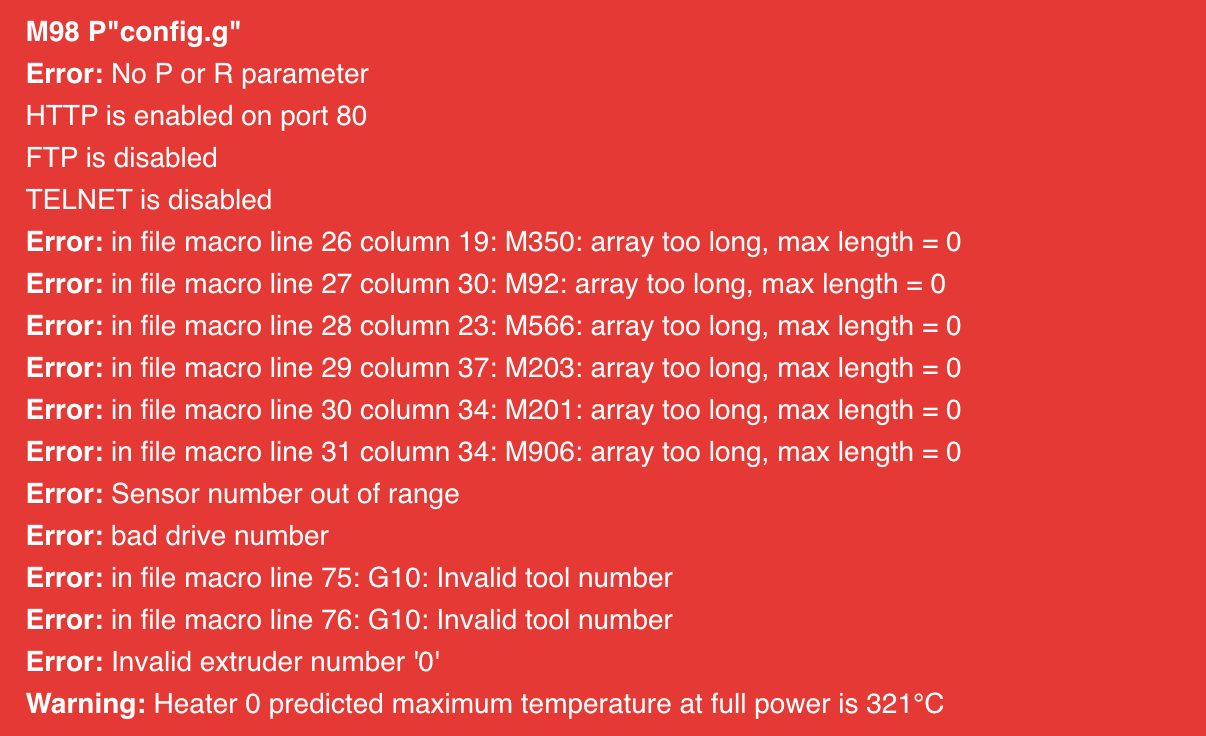

@Phaedrux Thanks! I Add M98:

I don't understand why drive 0 is not ok.

If I add D0 at M563 the tool 1 disappear...

-

Please copy and paste the text of your config.g here so we can see it all?

-

@Phaedrux Yes!

; Configuration file for Duet WiFi (firmware version 1.21) ; executed by the firmware on start-up ; ; generated by RepRapFirmware Configuration Tool v2 on Mon Mar 25 2019 12:03:15 GMT+0100 (CET) M98 ; General preferences G90 ; Send absolute coordinates... M83 ; ...but relative extruder moves M665 R280.8 L515 B200 H572.95 X0.0 Y0.0 Z0.0 ; Set delta radius, diagonal rod length, printable radius and homed height M666 X0.0 Y0.0 Z0.0 A0 B0 ; Put your endstop adjustments here, or let auto calibration find them ; Network M550 P"Delta" ; Set machine name M551 P"KKKKKK" ; Set password M552 S1 ; Enable network M587 S"YYYYYYY" P"XXXXXX" I192.168.1.230 J192.168.1.1 K255.255.255.0 ; Configure access point and IP addresses. You can delete this line once connected M586 P0 S1 ; Enable HTTP M586 P1 S0 ; Disable FTP M586 P2 S0 ; Disable Telnet ; Drives M569 P0 S1 ; Drive 0 goes forwards M569 P1 S1 ; Drive 1 goes forwards M569 P2 S1 ; Drive 2 goes forwards M569 P3 S1 ; Drive 3 goes forwards M350 X16 Y16 Z16 E16 I1 ; Configure microstepping without interpolation M92 X200.00 Y200.00 Z200.00 E432 ; Set steps per mm M566 X600 Y600 Z2800 E6000.00 P1 ; Set maximum instantaneous speed changes (mm/min) M203 X18000.00 Y18000.00 Z18000.00 E900.00 ; Set maximum speeds (mm/min) M201 X3000.00 Y3000.00 Z3000.00 E5000.00 ; Set accelerations (mm/s^2) M906 X1600.00 Y1600.00 Z1600.00 E1000.00 I30 ; Set motor currents (mA) and motor idle factor in per cent M84 S30 ; Set idle timeout ; Axis Limits M208 Z0 S1 ; Set minimum Z ; Endstops M574 X2 P"xstop" S1 M574 Y2 P"ystop" S1 M574 Z2 P"zstop" S1 ; Z-Probe M558 P1 C"!zprobe.in" R0.4 F240 H10 T3600 G31 X0 Y0 Z-0.1 P540 M557 R190 S20 ; Define mesh grid ; Heaters M308 S0 P"e1temp" Y"thermistor" T100000 B4138 ; configure sensor 0 as thermistor on pin e1temp M950 H0 C"e1heat" T0 ; create bed heater output on e1heat and map it to sensor 0 M307 H0 B1 S1.00 ; enable bang-bang mode for the bed heater and set PWM limit M140 H0 ; map heated bed to heater 0 M143 H0 S120 ; set temperature limit for heater 0 to 120C M308 S1 P"spi.cs1" Y"rtd-max31865" ; configure sensor 1 as PT100 on pin spi.cs1 M950 H1 C"bedheat" T1 ; create nozzle heater output on bedheat and map it to sensor 1 M307 H1 B0 S1.00 ; disable bang-bang mode for heater and set PWM limit M143 H1 S280 ; set temperature limit for heater 1 to 280C ; Fans M950 F0 C"fan0" Q500 ; create fan 0 on pin fan0 and set its frequency M106 P0 S0 H-1 ; set fan 0 value. Thermostatic control is turned off ;CPU Fan - NOT WORKING M912 P0 S3 ;Calibration CPU Temperature M950 F2 C"fan2" Q500 M106 P2 T25:65 H100:101:102 L130 ;Cooling board ; Tools ;M563 P1 S"tool1" H1 F0 ; define tool 1 M563 P1 S"tool1" H1 F0 D0 G10 P1 X0 Y0 Z0 ; set tool 1 axis offsets G10 P1 R0 S0 ; set initial tool 1 active and standby temperatures to 0C M204 P1800 M579 X1.004 Y1.01 ;M591 D0 P1 C"e1stop" S1 ;Sensore di Fine_Filo M572 D0 S0.05 ;M955 P0 C"spi.cs4+spi.cs3" ;Accelerometer M501 ; Automatic saving after power loss is not enabled ; Custom settings are not configured -

@samu_87 said in Duet Wifi - Accel:

M98

You have a random M98 at the start on your config. That's one of the errors so remove that.

@samu_87 said in Duet Wifi - Accel:

M587 S"" P"" I192.168.1.230 J192.168.1.1 K255.255.255.0

Remove this from config.g it only needs to be sent once.

You're missing an M584 command to bind the drives to axis.

AddM584 X0 Y1 Z2 E3after the M569 commands, but you must verify that that mapping is correct as I do not know which driver you have your motors plugged into.; Drives M569 P0 S1 ; Drive 0 goes forwards M569 P1 S1 ; Drive 1 goes forwards M569 P2 S1 ; Drive 2 goes forwards M569 P3 S1 ; Drive 3 goes forwards M350 X16 Y16 Z16 E16 I1 ; Configure microstepping without interpolation M92 X200.00 Y200.00 Z200.00 E432 ; Set steps per mm M566 X600 Y600 Z2800 E6000.00 P1 ; Set maximum instantaneous speed changes (mm/min) M203 X18000.00 Y18000.00 Z18000.00 E900.00 ; Set maximum speeds (mm/min) M201 X3000.00 Y3000.00 Z3000.00 E5000.00 ; Set accelerations (mm/s^2) M906 X1600.00 Y1600.00 Z1600.00 E1000.00 I30 ; Set motor currents (mA) and motor idle factor in per cent M84 S30There's a problem with your cpu fan command as well.

;CPU Fan - NOT WORKING M912 P0 S3 ;Calibration CPU Temperature M950 F2 C"fan2" Q500 M106 P2 T25:65 H100:101:102 L130H100:101:102is no longer valid. You can see how it's done now in RRF3 here: https://docs.duet3d.com/en/User_manual/Connecting_hardware/Temperature_configuring_mcu_tempThat's a good start. Make those corrections and send M98 P"config.g" again and then share the results of that and your updated config.g.

-

@Phaedrux Many Thanks!

Now the Fan works but the extrude button is not enabled:; Configuration file for Duet WiFi (firmware version 1.21) ; executed by the firmware on start-up ; ; generated by RepRapFirmware Configuration Tool v2 on Mon Mar 25 2019 12:03:15 GMT+0100 (CET) ; General preferences G90 ; Send absolute coordinates... M83 ; ...but relative extruder moves M665 R280.8 L515 B200 H572.95 X0.0 Y0.0 Z0.0 ; Set delta radius, diagonal rod length, printable radius and homed height M666 X0.0 Y0.0 Z0.0 A0 B0 ; Put your endstop adjustments here, or let auto calibration find them ; Network M550 P"Delta" ; Set machine name M551 P"samufree" ; Set password M552 S1 ; Enable network M586 P0 S1 ; Enable HTTP M586 P1 S0 ; Disable FTP M586 P2 S0 ; Disable Telnet ; Drives M569 P0 S1 ; Drive 0 goes forwards M569 P1 S1 ; Drive 1 goes forwards M569 P2 S1 ; Drive 2 goes forwards M569 P3 S1 ; Drive 3 goes forwards M584 X0 Y1 Z2 E3 M350 X16 Y16 Z16 E16 I1 ; Configure microstepping without interpolation M92 X200.00 Y200.00 Z200.00 E432 ; Set steps per mm M566 X600 Y600 Z2800 E6000.00 P1 ; Set maximum instantaneous speed changes (mm/min) M203 X18000.00 Y18000.00 Z18000.00 E900.00 ; Set maximum speeds (mm/min) M201 X3000.00 Y3000.00 Z3000.00 E5000.00 ; Set accelerations (mm/s^2) M906 X1600.00 Y1600.00 Z1600.00 E1000.00 I30 ; Set motor currents (mA) and motor idle factor in per cent M84 S30 ; Set idle timeout ; Axis Limits M208 Z0 S1 ; Set minimum Z ; Endstops M574 X2 P"xstop" S1 M574 Y2 P"ystop" S1 M574 Z2 P"zstop" S1 ; Z-Probe M558 P1 C"!zprobe.in" R0.4 F240 H10 T3600 G31 X0 Y0 Z-0.1 P540 M557 R190 S20 ; Define mesh grid ; Heaters M308 S0 P"e1temp" Y"thermistor" T100000 B4138 ; configure sensor 0 as thermistor on pin e1temp M950 H0 C"e1heat" T0 ; create bed heater output on e1heat and map it to sensor 0 M307 H0 B1 S1.00 ; enable bang-bang mode for the bed heater and set PWM limit M140 H0 ; map heated bed to heater 0 M143 H0 S120 ; set temperature limit for heater 0 to 120C M308 S1 P"spi.cs1" Y"rtd-max31865" ; configure sensor 1 as PT100 on pin spi.cs1 M950 H1 C"bedheat" T1 ; create nozzle heater output on bedheat and map it to sensor 1 M307 H1 B0 S1.00 ; disable bang-bang mode for heater and set PWM limit M143 H1 S280 ; set temperature limit for heater 1 to 280C ; Fans M950 F0 C"fan0" Q500 ; create fan 0 on pin fan0 and set its frequency M106 P0 S0 H-1 ; set fan 0 value. Thermostatic control is turned off ;CPU Fan - NOT WORKING M308 S3 Y"mcu-temp" A"MCU" ; configure sensor 3 as on-chip MCU temperature sensor M950 F2 C"fan2" Q100 ; create fan 2 on pin fan2 and set its frequency M106 P2 H3 T20:70 ; set fan 2 value ; Tools ;M563 P1 S"tool1" H1 F0 ; define tool 1 M563 P1 S"tool1" H1 F0 D0 G10 P1 X0 Y0 Z0 ; set tool 1 axis offsets G10 P1 R0 S0 ; set initial tool 1 active and standby temperatures to 0C M204 P1800 M579 X1.004 Y1.01 ;M591 D0 P1 C"e1stop" S1 ;Sensore di Fine_Filo M572 D0 S0.05 ;M955 P0 C"spi.cs4+spi.cs3" ;Accelerometer M501 ; Automatic saving after power loss is not enabled ; Custom settings are not configuredThe driver motor are connected like here:

https://docs.duet3d.com/Duet3D_hardware/Duet_2_family/Duet_2_WiFi_Ethernet_Hardware_Overview#pin-namesExtruder stepper in E0 Stepper, but still not work...

-

Can you send M98 P"config.g" again and share the results please?

You also need to have a tool selected before you can extrude with it, please add

T0to the end of your config.g so that your tool is selected at startup.The extruder will also not work unless the hotend is at temperature by default unless you have cold extrusion enabled for testing.

-

@Phaedrux Now is good it was T1 not T0

If you want can you help me to configure command M591 to filament runout and the accelerometer that I have to connect to the daughter because i have MAX31865 for PT100.

Thanks a lot!

-

Ah yes, I missed that.

M563 P1 S"tool1" H1 F0 D0 G10 P1 X0 Y0 Z0 ; set tool 1 axis offsets G10 P1 R0 S0 ; set initial tool 1 active and standby temperatures to 0CYou should change those P1 to P0. Then T0 would be correct.

The tools start counting from 0.

@samu_87 said in Duet Wifi - Accel:

If you want can you help me to configure command M591 to filament runout and the accelerometer that I have to connect to the daughter because i have MAX31865 for PT100.

See here

https://docs.duet3d.com/en/User_manual/Connecting_hardware/Sensors_filamenthttps://docs.duet3d.com/User_manual/Connecting_hardware/Sensors_Accelerometer

-

@Phaedrux said in Duet Wifi - Accel:

Ah yes, I missed that.

M563 P1 S"tool1" H1 F0 D0 G10 P1 X0 Y0 Z0 ; set tool 1 axis offsets G10 P1 R0 S0 ; set initial tool 1 active and standby temperatures to 0CYou should change those P1 to P0. Then T0 would be correct.

The tools start counting from 0.

@samu_87 said in Duet Wifi - Accel:

If you want can you help me to configure command M591 to filament runout and the accelerometer that I have to connect to the daughter because i have MAX31865 for PT100.

See here

https://docs.duet3d.com/en/User_manual/Connecting_hardware/Sensors_filamenthttps://docs.duet3d.com/User_manual/Connecting_hardware/Sensors_Accelerometer

Ok Thanks now I think work all fine:

I don't Sundstrand why when the axes are not homed x=0 Y=0 and Z is max hight and why the preset selected on T0 is -273,1Thanks!

-

@Phaedrux Sorry but now when I wake up the printer the tool 0 is active, I don't like this, it can be fix?

; Configuration file for Duet WiFi (firmware version 1.21) ; executed by the firmware on start-up ; ; generated by RepRapFirmware Configuration Tool v2 on Mon Mar 25 2019 12:03:15 GMT+0100 (CET) ; General preferences G90 ; Send absolute coordinates... M83 ; ...but relative extruder moves M665 R280.8 L515 B200 H572.95 X0.0 Y0.0 Z0.0 ; Set delta radius, diagonal rod length, printable radius and homed height M666 X0.0 Y0.0 Z0.0 A0 B0 ; Put your endstop adjustments here, or let auto calibration find them ; Network M550 P"Delta" ; Set machine name M551 P"samufree" ; Set password M552 S1 ; Enable network M586 P0 S1 ; Enable HTTP M586 P1 S0 ; Disable FTP M586 P2 S0 ; Disable Telnet ; Drives M569 P0 S1 ; Drive 0 goes forwards M569 P1 S1 ; Drive 1 goes forwards M569 P2 S1 ; Drive 2 goes forwards M569 P3 S1 ; Drive 3 goes forwards M584 X0 Y1 Z2 E3 M350 X16 Y16 Z16 E16 I1 ; Configure microstepping without interpolation M92 X200.00 Y200.00 Z200.00 E432 ; Set steps per mm M566 X600 Y600 Z2800 E6000.00 P1 ; Set maximum instantaneous speed changes (mm/min) M203 X18000.00 Y18000.00 Z18000.00 E900.00 ; Set maximum speeds (mm/min) M201 X3000.00 Y3000.00 Z3000.00 E5000.00 ; Set accelerations (mm/s^2) M906 X1600.00 Y1600.00 Z1600.00 E1000.00 I30 ; Set motor currents (mA) and motor idle factor in per cent M84 S30 ; Set idle timeout ; Axis Limits M208 Z0 S1 ; Set minimum Z ; Endstops M574 X2 P"xstop" S1 M574 Y2 P"ystop" S1 M574 Z2 P"zstop" S1 ; Z-Probe M558 P1 C"!zprobe.in" R0.4 F240 H10 T3600 G31 X0 Y0 Z-0.1 P530 M557 R190 S20 ; Define mesh grid ; Heaters M308 S0 P"e1temp" Y"thermistor" T100000 B4138 ; configure sensor 0 as thermistor on pin e1temp M950 H0 C"e1heat" T0 ; create bed heater output on e1heat and map it to sensor 0 M307 H0 B1 S1.00 ; enable bang-bang mode for the bed heater and set PWM limit M140 H0 ; map heated bed to heater 0 M143 H0 S120 ; set temperature limit for heater 0 to 120C M308 S1 P"spi.cs1" Y"rtd-max31865" ; configure sensor 1 as PT100 on pin spi.cs1 M950 H1 C"bedheat" T1 ; create nozzle heater output on bedheat and map it to sensor 1 M307 H1 B0 S1.00 ; disable bang-bang mode for heater and set PWM limit M143 H1 S280 ; set temperature limit for heater 1 to 280C ; Fans M950 F0 C"fan0" Q500 ; create fan 0 on pin fan0 and set its frequency M106 P0 S0 H-1 ; set fan 0 value. Thermostatic control is turned off ;CPU Fan M308 S3 Y"mcu-temp" A"MCU" ; configure sensor 3 as on-chip MCU temperature sensor M950 F2 C"fan2" Q100 ; create fan 2 on pin fan2 and set its frequency M106 P2 H3 T20:70 ; set fan 2 value ; Tools M563 P0 S"tool1" H1 F0 D0 ; define tool 1 G10 P0 X0 Y0 Z0 ; set tool 1 axis offsets G10 P0 R0 S0 ; set initial tool 1 active and standby temperatures to 0C M204 P1800 M579 X1.004 Y1.01 M591 D0 P1 C"e0stop" S1 ;Sensore di Fine_Filo M572 D0 S0.05 ;M955 P0 C"spi.cs4+spi.cs3" ;Accelerometer T0 ;Enable Extruder M501 ; Automatic saving after power loss is not enabled ; Custom settings are not configured -

Do you actually have a PT100 and daughterboard on the hotend?

I think you have your bed heater and hotend heater defined backwards.

You have

; Heaters M308 S0 P"e1temp" Y"thermistor" T100000 B4138 ; configure sensor 0 as thermistor on pin e1temp M950 H0 C"e1heat" T0 ; create bed heater output on e1heat and map it to sensor 0 M307 H0 B1 S1.00 ; enable bang-bang mode for the bed heater and set PWM limit M140 H0 ; map heated bed to heater 0 M143 H0 S120 ; set temperature limit for heater 0 to 120C M308 S1 P"spi.cs1" Y"rtd-max31865" ; configure sensor 1 as PT100 on pin spi.cs1 M950 H1 C"bedheat" T1 ; create nozzle heater output on bedheat and map it to sensor 1 M307 H1 B0 S1.00 ; disable bang-bang mode for heater and set PWM limit M143 H1 S280 ; set temperature limit for heater 1 to 280CIt should probably be this. Where exactly do you have the bed and hotend heaters connected?

; Heaters M308 S0 P"bedtemp" Y"thermistor" T100000 B4138 ; configure sensor 0 as thermistor on pin bedtemp M950 H0 C"bedheat" T0 ; create bed heater output on bedheat and map it to sensor 0 M307 H0 B1 S1.00 ; enable bang-bang mode for the bed heater and set PWM limit M140 H0 ; map heated bed to heater 0 M143 H0 S120 ; set temperature limit for heater 0 to 120C M308 S1 P"spi.cs1" Y"rtd-max31865" ; configure sensor 1 as PT100 on pin spi.cs1 M950 H1 C"e0heat" T1 ; create nozzle heater output on e0heat and map it to sensor 1 M307 H1 B0 S1.00 ; disable bang-bang mode for heater and set PWM limit M143 H1 S280 ; set temperature limit for heater 1 to 280CHeater 0 is typically the bed. Heater1 is typically the first tool heater.

@samu_87 said in Duet Wifi - Accel:

I don't Sundstrand why when the axes are not homed x=0 Y=0 and Z is max hight and why the preset selected on T0 is -273,1

I don't know what you mean by this. The axis are only homed after running homeall. When the motors lose power they lose position and need to be rehomed.

@samu_87 said in Duet Wifi - Accel:

Sorry but now when I wake up the printer the tool 0 is active, I don't like this, it can be fix?

Active just means that it is the currently selected tool. If you don't want it active at startup you must remember to activate it manually by clicking on the tool or sending T0 in the slicer start gcode.

-

@Phaedrux Yes I have the hotend wired in that way:

- power on bedheat pin

- control with MAX on daughter board

Heated Bed:

- Power on e1

- sensor on e1

This because i have a powerful heat cartiage on the extruder and a mosfet to control heated bed so i invert this because the bed mosfet on duet wifi handle more current.

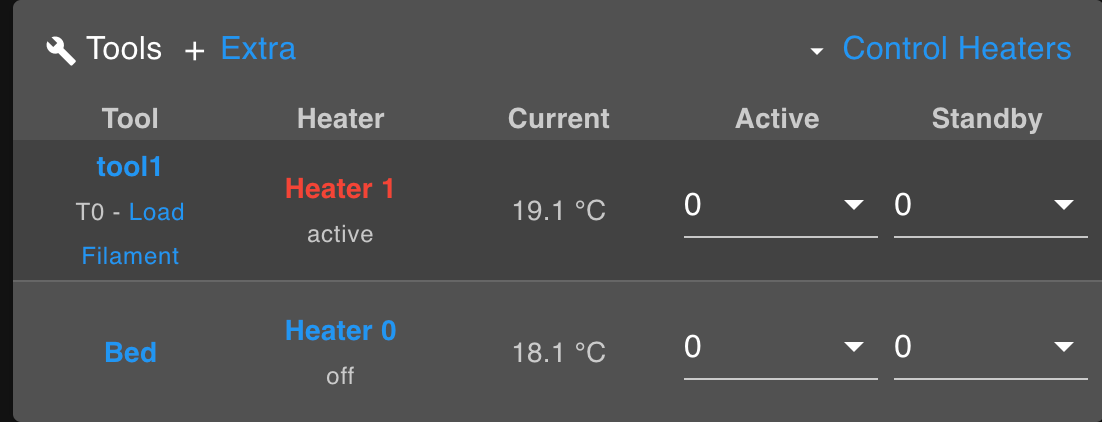

Maybe is useless but I hope that don't make a problema,I've been using this for about 4 years.When i power on the printer I find the heater 1 active and not off like the bed, see this image:

-

@Phaedrux said in Duet Wifi - Accel:

Active just means that it is the currently selected tool. If you don't want it active at startup you must remember to activate it manually by clicking on the tool or sending T0 in the slicer start gcode.

Now I have understand what do you mean, I'm used to the old graphics and every time I enable the Tool manually. I delete T0 in config.g and I'm okay

-

@Phaedrux

Hello, Thanks a lot because all work well now.

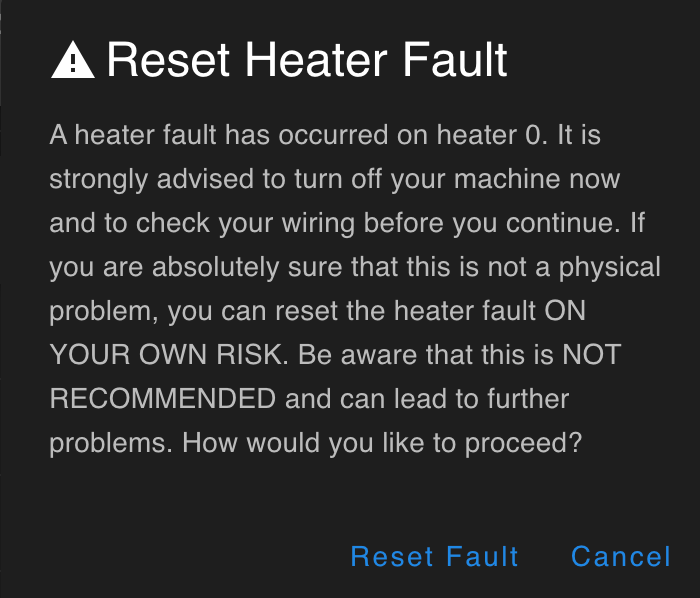

The heated bed sometimes give me this:

I'm sure that the wiring etc is all okay, I have a big heated bed with low power so it spend a lot of time to heating up.

how I can modify that to give them more time?

M307 H0 R0.186 K0.226:0.000 D1.09 E1.35 S1.00 B1Thanks!!!

-

What is the fault error that you're getting in the console?

Can you send

M308 S0after you get a fault and report back with that message it gives you?What does the heater graph look like when it faults?

-

@Phaedrux As soon as the error occurs again I will give you the necessary data.

It usually comes back early in the morning when it's cold, I have a lot of mass to heat up so it takes a little longer than usual and gives an error. For now, thank you very much! -

M308 S0 Sensor 0 type Thermistor using pin e1temp, reading 82.2, last error: sensor not ready, T:100000.0 B:4138.0 C:0.00e+0 R:4700.0 L:0 H:0Here the error... in a cold day the temperature rise slowly and the error appear.

Many thanks!

-

Can you try changing the R and D values in your M307 command to match this?

M307 H0 R0.25 K0.226:0.000 D2 E1.35 S1.00 B1 -

@Phaedrux

Yes I will try! What change R and D?Thanks!