Delta with 1HCL very strange movement, need HELP

-

Hello to all!!

We build a very nice Delta Machine 2100mm towers high 920mm bed diameter (printing surface) ,1054mm diagonal rods, 547 delta radius.

we use Duet 3 v1.01, SmartEffector v2.0 with BondTech LGX Lite and The Mosquito Hoten, 1HCL CAN bus card driving the motors.

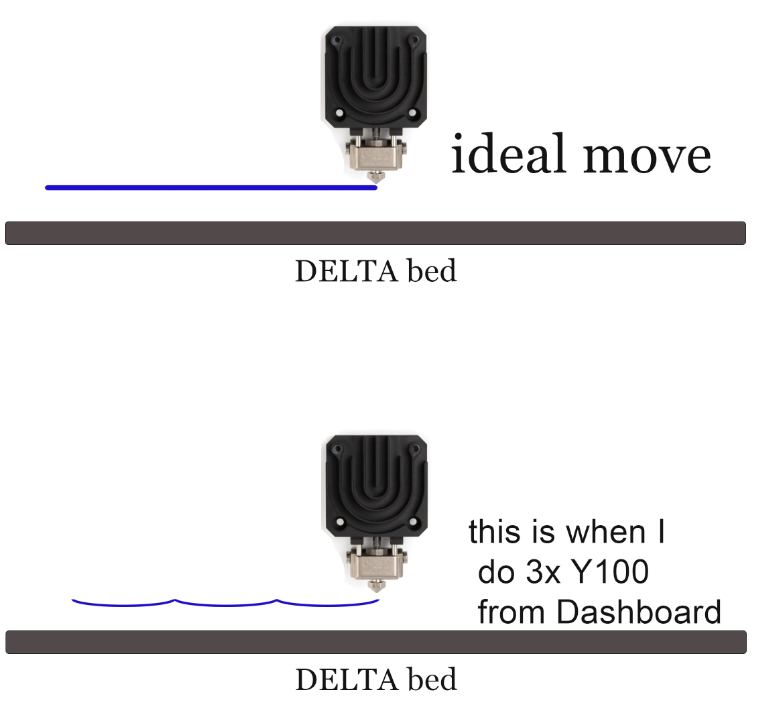

Every thing working perfectly... there is a problem though , after every possible procedure of calibration, bed mash compensation, the printer head is not moving in straight line even if the movement is spot on to measured size. is hard to explain but when i give Y100 the start point of the nozzle are at exact high with stop point but between start and stop we have a parabolic / convex line... toward bed.

I am trying to show in this picture what happen. parabolic high for 100mm of move is about 3-4 mm and become 10-13mm if i do G1 Y300 .

we make all kind of test... shorten and lengthen the size of roads and radius (in config.g i mean) apart changing the travel size the parabolic movement is still there. so.. HELP we need. i mention, we build many other printers, but this one is the first with Duet3 and 1HCl interface.

Thanks .

-

@jesyblue we don't currently support driving the tower motors of a delta printers using CAN-connected expansion boards. See https://docs.duet3d.com/en/User_manual/RepRapFirmware/CAN_limitations#temporary-limitations. We had scheduled implementation of this in RRF 3.5 but it may now be delayed until 3.6.

That said, you may find that it works sufficiently well if you enable segmentation. To do this, use M669 with only S and T parameters (do not use a K parameter). The M669 command must come later in config.g than the M665 command, or you can send it manually from the DWC console. I suggest you try a segment length of 1mm or 2mm.

-

@dc42 thank you for your very quick answer, yes, indeed, i found M669 command right after i post on forum. M669 S5 T1 fix the problem. at last i can't see any problem at naked eye on the extrusion.

-

undefined Phaedrux marked this topic as a question

undefined Phaedrux marked this topic as a question

-

undefined Phaedrux has marked this topic as solved

undefined Phaedrux has marked this topic as solved