G29 strange behavior on X movement

-

Hi,

i am new to Duet, and the printer which i want to use is also new to me ( corexy )

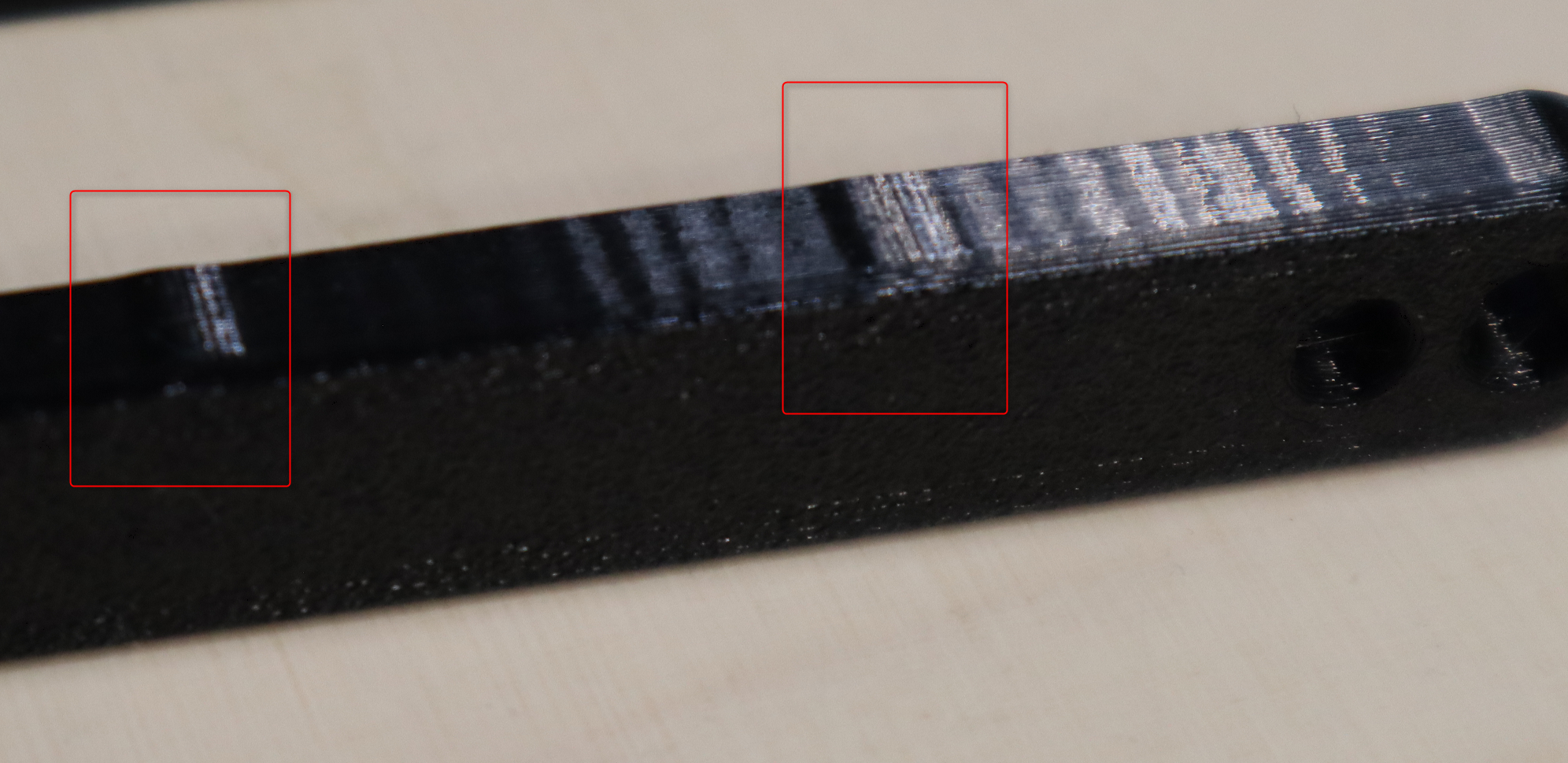

I get a strange resulst, when i try to print just a straight line, as you can see in the picture.

Video with G29 S1

Video with G29 S2Hardware:

-

Duet 3 Main Board 6HC with raspberry pi

-

Duet 3 Tool Board 1LC

Does anyone got a hint, what could cause this problem ?

What i expect, at a moment with G29 S1 like G29 S2 -

-

@arminp It's possible that the speed of your movement is being limited because the system has to adjust in Z for the mesh-bed levelling correction.

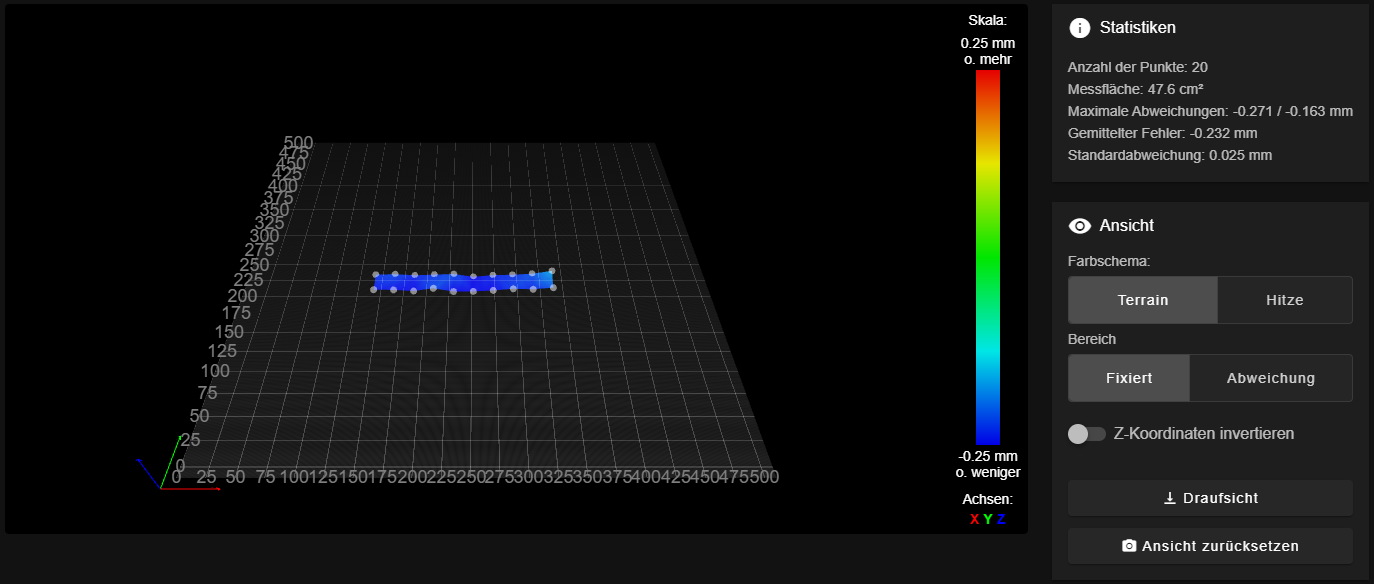

What would be good to see is an image of your mesh as well as config.g.

The mesh will show if it's got a normal amount of correction or if it's got an excessive amount of correction in those areas.

The config.g will show if maybe you've got slow maximum Z movement, acceleration or jerk settings.

People who know a lot more than I do will be able to help more.

-

I use a standard configuration for this printer, so i am not sure if the speeds are ok.

Bedmesh

config.g

G90 ; send absolute coordinates... M83 ; ...but relative extruder moves M550 P"V-Core 3" ; set printer name M669 K1 ; CoreXY G29 S1 ; Set Units to Millimeters G4 S2 ; wait for expansion boards to start M955 P121.0 I54 M593 P"mzv" F57.9 ; Network ;M552 P0.0.0.0 S1 ; enable network and acquire dynamic address via DHCP M586 P0 S1 ; enable HTTP M586 P1 S0 ; disable FTP M586 P2 S0 ; disable Telnet ; Drives M569 P0.0 S1 D2 V10 ; physical drive 0.0 goes forwards M569 P0.1 S1 D2 V10 ; physical drive 0.1 goes forwards M569 P0.2 S1 D2 V10 ; physical drive 0.2 goes forwards M569 P0.5 S0 D2 ; physical drive 0.3 goes forwards M569 P0.4 S0 D2 ; physical drive 0.4 goes forwards M569 P121.0 S1 D2 ; physical drive 0.5 goes forwards M584 X0.4 Y0.5 Z0.0:0.1:0.2 E121.0 ; set drive mapping M350 X16 Y16 Z16 E16 I1 ; configure microstepping with interpolation M92 X80.00 Y80.00 Z800.00 E699.36 ; set steps per mm M906 X1600 Y1600 Z1600 I30 ; set motor currents (mA) and motor idle factor in per cent M906 E1200 I10 M207 S1.5 F7200 Z0.2 M84 S30 ; Set idle timeout M566 X400.00 Y400.00 Z6.00 E300.00 P1 ; set maximum instantaneous speed changes (mm/min) M203 X10800.00 Y10800.00 Z1000.00 E7200.00 ; set maximum speeds (mm/min) M201 X3000.00 Y3000.00 Z100.00 E10000 ; set accelerations (mm/s^2) ; Axis Limits M208 X0 Y-10 Z0 S1 ; set axis minima M208 X510 Y500 Z500 S0 ; set axis maxima ; Endstops M574 X1 S1 P"121.io1.in" ; configure active high endstops M574 Y2 S1 P"io1.in" ; configure active high endstops M671 X-4.5:250:504.5 Y0:505:0 S5 ; define positions of Z leadscrews or bed levelling screws M557 X20:480 Y20:480 P5 ; define 5x5 mesh grid ; Heaters M308 S0 P"temp0" Y"thermistor" T100000 B3950 A"Bed" ; configure sensor 0 as thermistor on pin temp0 M950 H0 C"out1" T0 ; create bed heater output on out5 and map it to sensor 0 M307 H0 B0 S1.00 ; disable bang-bang mode for the bed heater and set PWM limit M140 H0 ; map heated bed to heater 0 M143 H0 S110 ; set temperature limit for heater 0 to 110C M308 S1 P"121.temp1" Y"thermistor" T100000 B4267 A"Hotend" ; configure sensor 1 as thermistor on pin 121.temp0 M950 H1 C"121.out0" T1 ; create nozzle heater output on 121.out0 and map it to sensor 1 M307 H1 B0 S1.00 ; disable bang-bang mode for heater and set PWM limit M143 H1 S280 M308 S1 H4 M308 S1 L-114 ; set temperature limit for heater 1 to 280C ;; Run Heater PID Tune!! M307 H1 R3.375 K0.385:0.000 D5.99 E1.35 S1.00 B0 V24.1 ;; Run Bed PID Tune!! Bellow is an example for a 300x300 bed M307 H0 R0.538 K0.254:0.000 D3.41 E1.35 S1.00 B0 ; Fans M950 F0 C"121.out1" Q500 ; create fan 0 on pin out3 and set its frequency M106 P0 C"Hotend Fan" S0 H1 T45 L255 ; set fan 0 name and value. Thermostatic control turned on for Hotend M950 F1 C"121.out2" Q500 ; create fan 1 on pin out4 and set its frequency M106 P1 C"Layer Fan" S0 H-1 L255 ; set fan 1 name and value. Thermostatic control is turned off ; Tools M563 P0 D0 H1 F1 ; define tool 0 G10 P0 X-4 Y-4 Z0 ; set tool 0 axis offsets G10 P0 R0 S0 ; set initial tool 0 active and standby temperatures to 0C ; EVA 2 / BMG / E3D V6 ; Z-Probe ;M950 S0 C"121.io0.out" ; create servo pin 0 for BLTouch M558 P5 C"io2.out" H2 F100:55 R0.2 T10800 A5 ; set Z probe type to bltouch and the dive height + speeds G31 P500 X-31 Y-22 Z2.75 ; set Z probe trigger value, offset and trigger height M557 X15:490 Y15:460 S23 ; define mesh grid ;; Inductive Probe ; M558 P5 C"!io3.in" H5 F400 T5000 ; set Z probe type to unmodulated and the dive height + speeds ; G31 P500 X-30 Y-15 Z0.20 ; set Z probe trigger value, offset and trigger height, more Z means closer to the bed ;; BLTouch ; M950 S0 C"io7.out" ; Create a servo pin on io7 ; M558 P9 C"io7.in" H5 F240 T10800 A5 ; set Z probe type to unmodulated and the dive height + speeds ; G31 P25 X-28.00 Y-13.00 Z0.90 ; set Z probe trigger value, offset and trigger height, more Z means closer to the bed M207 S1.5 F7200 Z0.2 T0 ;M556 S300 X2.16 M98 P"macros/startup/set_globals.g" -

The image shows only a small strip of the bed with a heightmap, so something has gone wrong with the creation of your heightmap.

@arminp said in G29 strange behavior on X movement:

; Tools

M563 P0 D0 H1 F1 ; define tool 0Why does your tool have a -4mm offset in both axis? tool0 would typically be at the 0,0 offset position.

M557 X15:490 Y15:460 S23

Based on this command it would seem that you need to re-run your mesh creation.

What probe exactly are you using?

@arminp said in G29 strange behavior on X movement:

; Z-Probe

;M950 S0 C"121.io0.out" ; create servo pin 0 for BLTouch

M558 P5 C"io2.out" H2 F100:55 R0.2 T10800 A5 ; set Z probe type to bltouch and the dive height + speeds

G31 P500 X-31 Y-22 Z2.75 ; set Z probe trigger value, offset and trigger heightThis is the only probe not commented out, but the comments contradict what I see configured. BLtouch would be probe type 9, and you'd need a servo pin defined.

-

@arminp said in G29 strange behavior on X movement:

M566 X400.00 Y400.00 Z6.00

Also, this shows your Z axis jerk value as 6mm/min which is very very slow and would explain the visible banding. Try setting that to 60 at a minimum.

-

Thank you for your help.

I increased the jerk value to 60 and the result is good now.The tool is at the wrong position, without the tool offset. I assumed that the right way to correct it.

I first used an BL-touch, but ist had vibrations at higher speed, so i changed to an klicky probe.

-

undefined Phaedrux marked this topic as a question

undefined Phaedrux marked this topic as a question

-

undefined Phaedrux has marked this topic as solved

undefined Phaedrux has marked this topic as solved