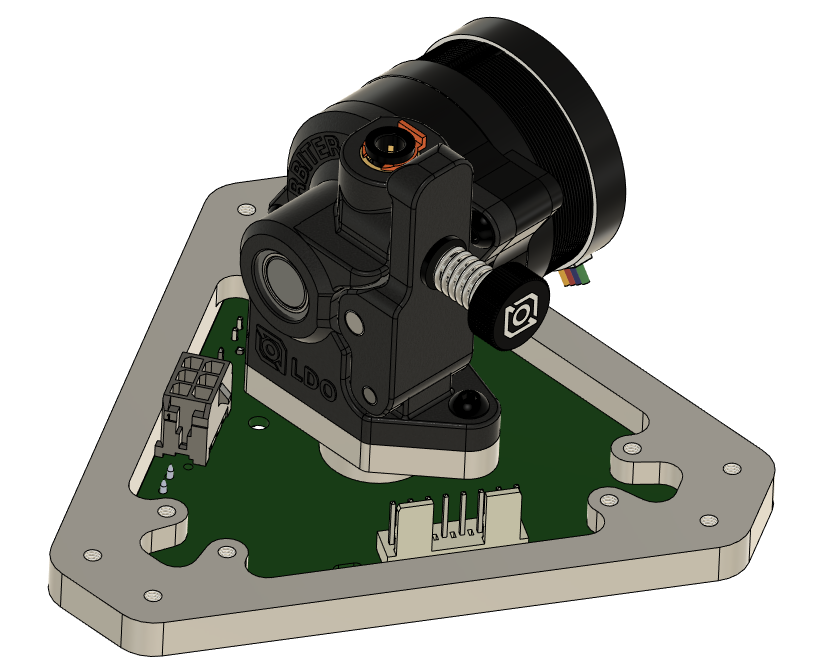

Orbiter 2 extruder mounting for Smart effector with Magball arms

-

@adrian52 Thanks a lot.

What plastic do you use/recommend for this part? -

@vapvap it works OK with PLA, although I am currently printing a set in nylon - will report if I can see a difference.

-

@dc42 I've made a quick and dirty model approximating how big the smart effector would need to be for me to be able to mount an Orbiter directly on-top of where the bolt is. With my specs it would need to be a distance of around 71.3 mm between the ball studs. I've angled the extruder by 15 degrees to make it take slightly less space in between the arms.

The cones visualize the maximum reach of the arms for my delta with a 350mm bed and 440mm arms.

Its probably possible to make it an even tighter fit by tweaking the parameters but I thought it was good enough to continue the discussion ¯\(ツ)/¯

-

@snimax thanks, that's very useful. Did you leave the spacing between adjacent ball studs in the corners the same, or did you increase that too?

-

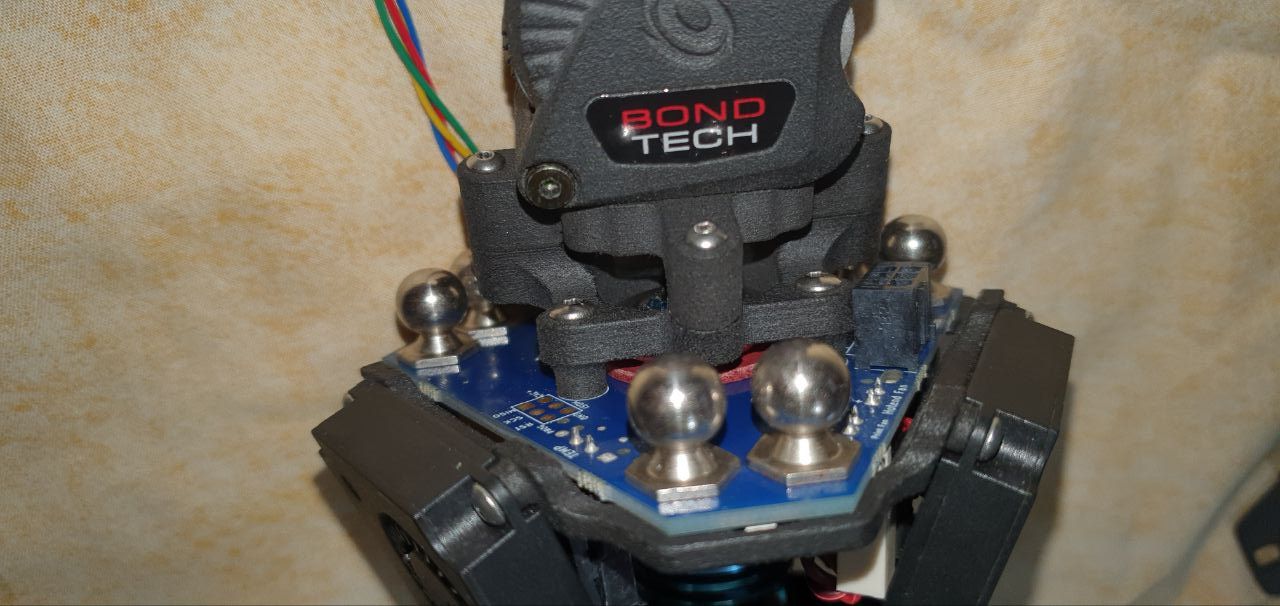

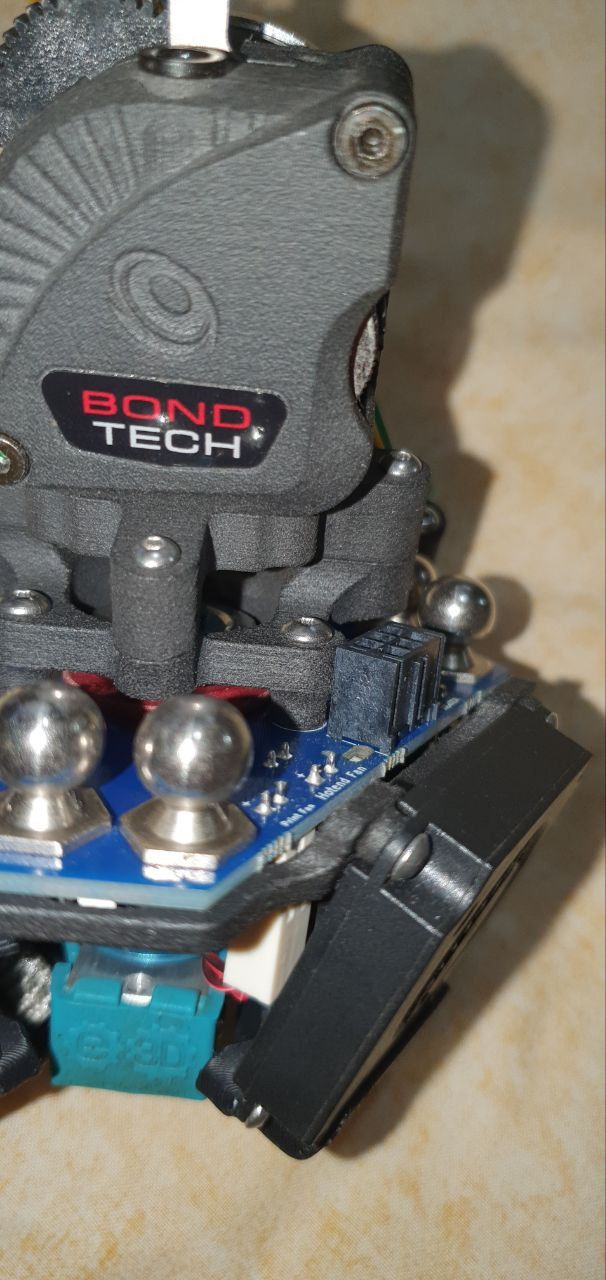

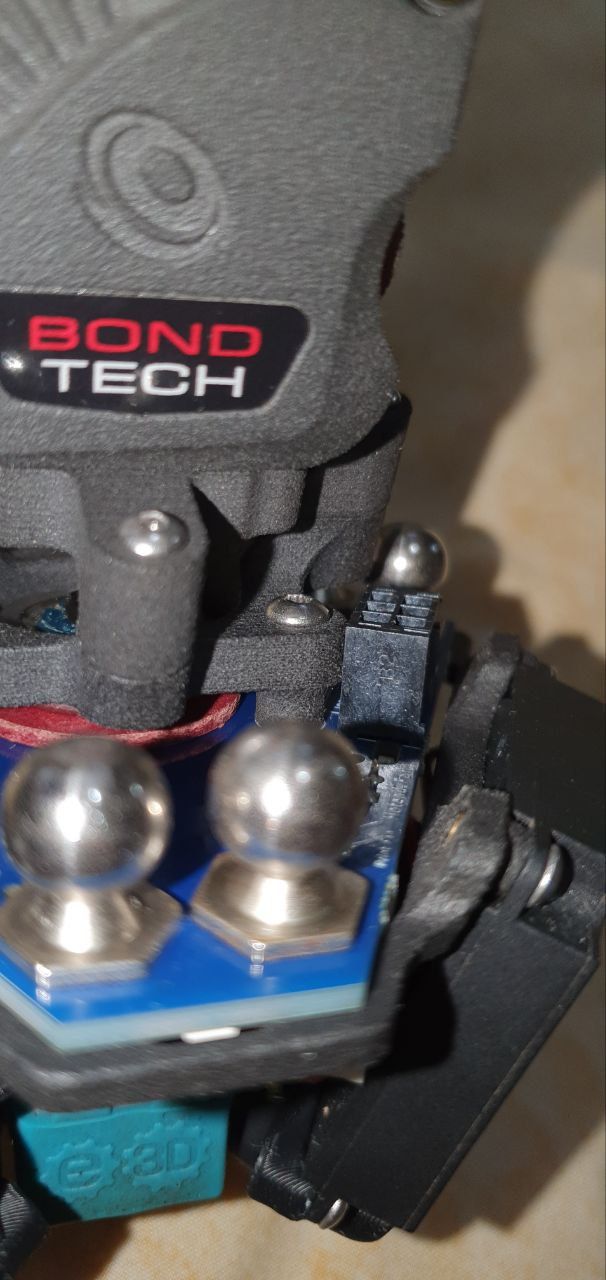

@snimax tried to take a picture of my version from the same viewpoint

I have maintained the 55mm spacing, and find a good fit with the motor orientated as shown. The effector is in its furthest 'Y' position, where the arms are closest to the motor.

-

@dc42 I tried to keep the spacing between the balls at the corners. I think there was a formula somewhere of the stability of the effector where you wanted to keep that spacing short but I cant recall where I saw it

@Adrian52 Looks good! I like the idea of having a straight and much shorter filament path, compared to my adapter where the filament is in a slight s-shape

Haven't gotten around to compare it yet though

Haven't gotten around to compare it yet though -

@dc42 I have now done an adapter that maintains the 12mm spacing of the magballs

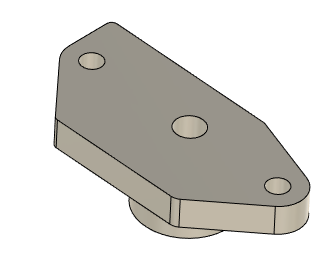

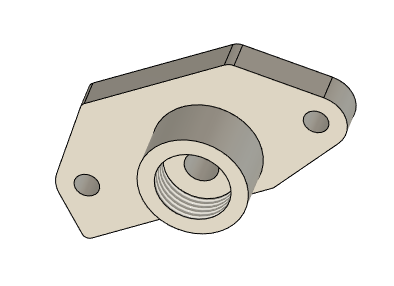

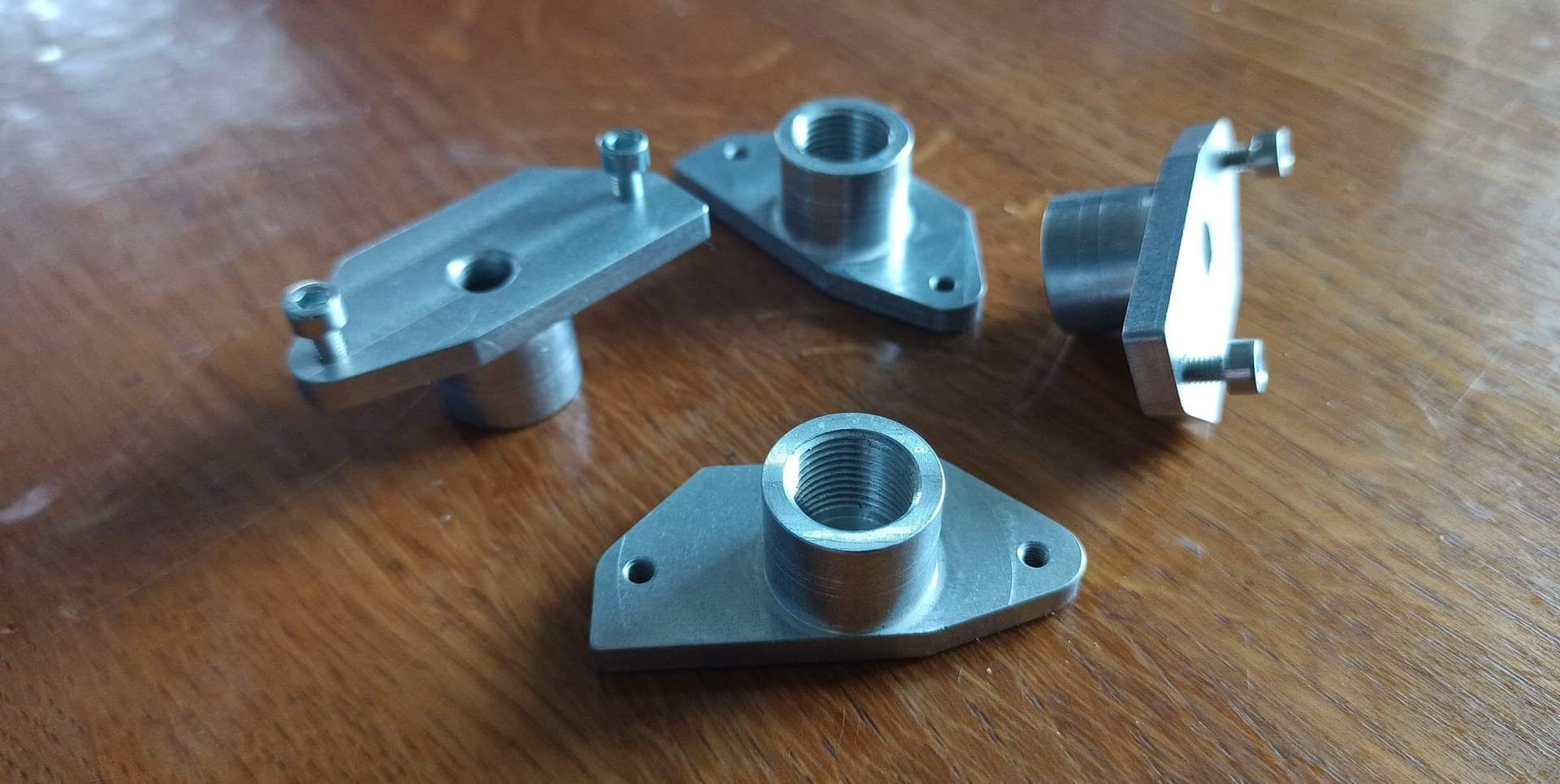

The carriage adapters look like this

I played with the offset, settling on moving the centre line of the studs 7.5mm from the base of the triangle. This gives very close (within 0.02mm) spacing of 81mm for the arms, requiring a 13mm spacer on each side of the carriage. As you can see, this gives plenty of room for the orbiter 2 mounted with a straight vertical filament path.

I have printed these in nylon using 80% infill, which seems to give a slightly better result than PLA .

Not much experience printing with this setup yet, but the initial impression is of increased precision over the 55mm arm separation.

-

@adrian52 thanks. Wider arm spacing is generally preferred, because it provides greater rigidity and less sensitivity to small geometric errors.

-

@dc42 I should have done my homework. According to the reprap wiki here , stability decreases linearly with ball gap, but increases with the square of arm gap. So compared to the standard geometry, keeping the arm gap decreases stability almost threefold, whilst the 12mm ball gap with wider arms more than doubles stability. I think I was so impressed with the improvement of direct drive over the bowden that I didn't consider the effect of geometry on stability.

-

@adrian52 As always, great idea!

And as usual - we are waiting for the addition to "thingiverse". -

@vapvap Thanks. Posted it now

-

@adrian52 Thank you so much for sharing your ideas with us.

Do you do any additional fine-tuning in the firmware? -

Can anyone explain how to set this up?

With "Delta Calibration (G32)", the nozzle began to scratch on the center of the table ... -

@vapvap have you run thru

https://docs.duet3d.com/en/User_manual/Tuning/Delta_calibration -

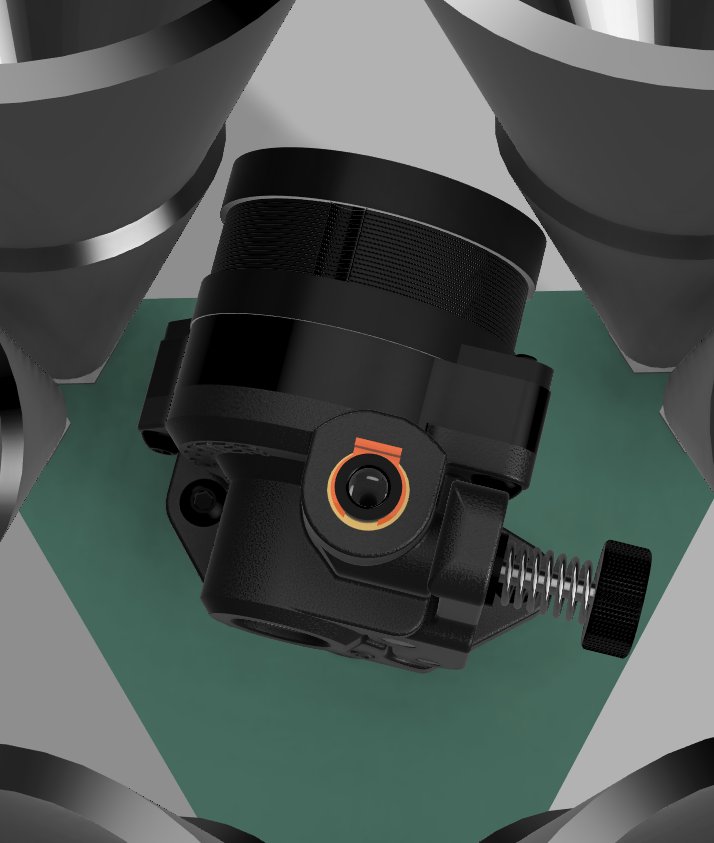

my LGX lite direct drive mount for smart effector for my 3 kossel printers

-

@Fred-Y I have been thinking of that solution for my Orbiter 2.0. With my 80mm rod spacing adapter the Orbiter can be mounted horizontally.

-

Made some mounts for the Orbiter 2.0. Works great with my 80mm smart effector adapter. Weight is 12 grams.

-

@weed2all possible to get the stl ?

-

@PCR yes...of course...I uploaded them to my thingiverse, just click on the signature and you go directly to my thingiverse page!