Help tune out "printer seam"

-

It doesn't sound like you're actually using vase mode in your slicer at all.

-

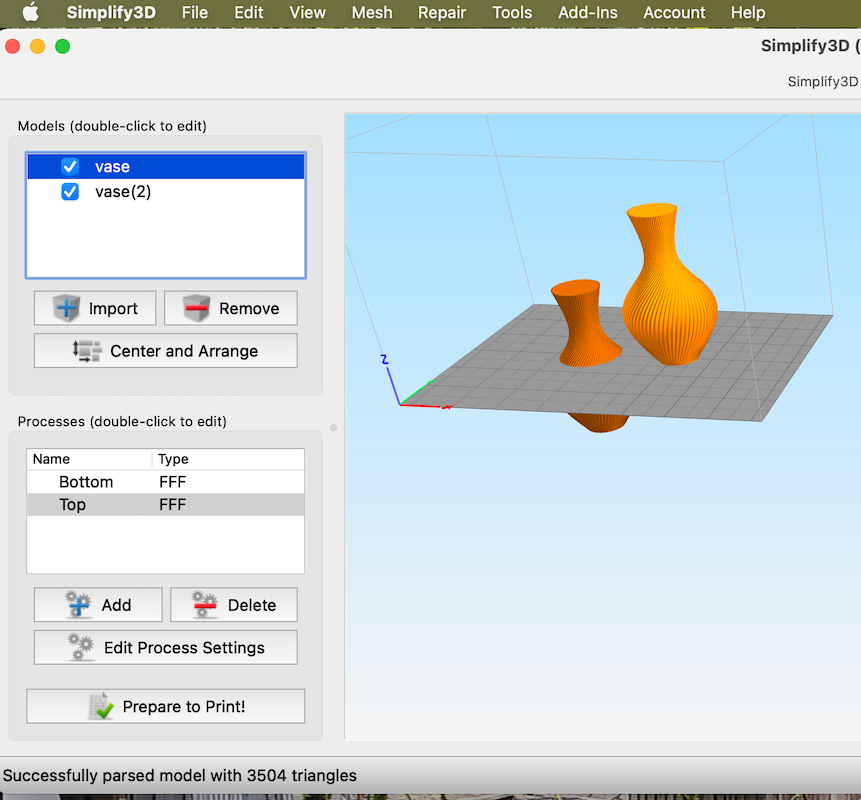

Simplify3D...

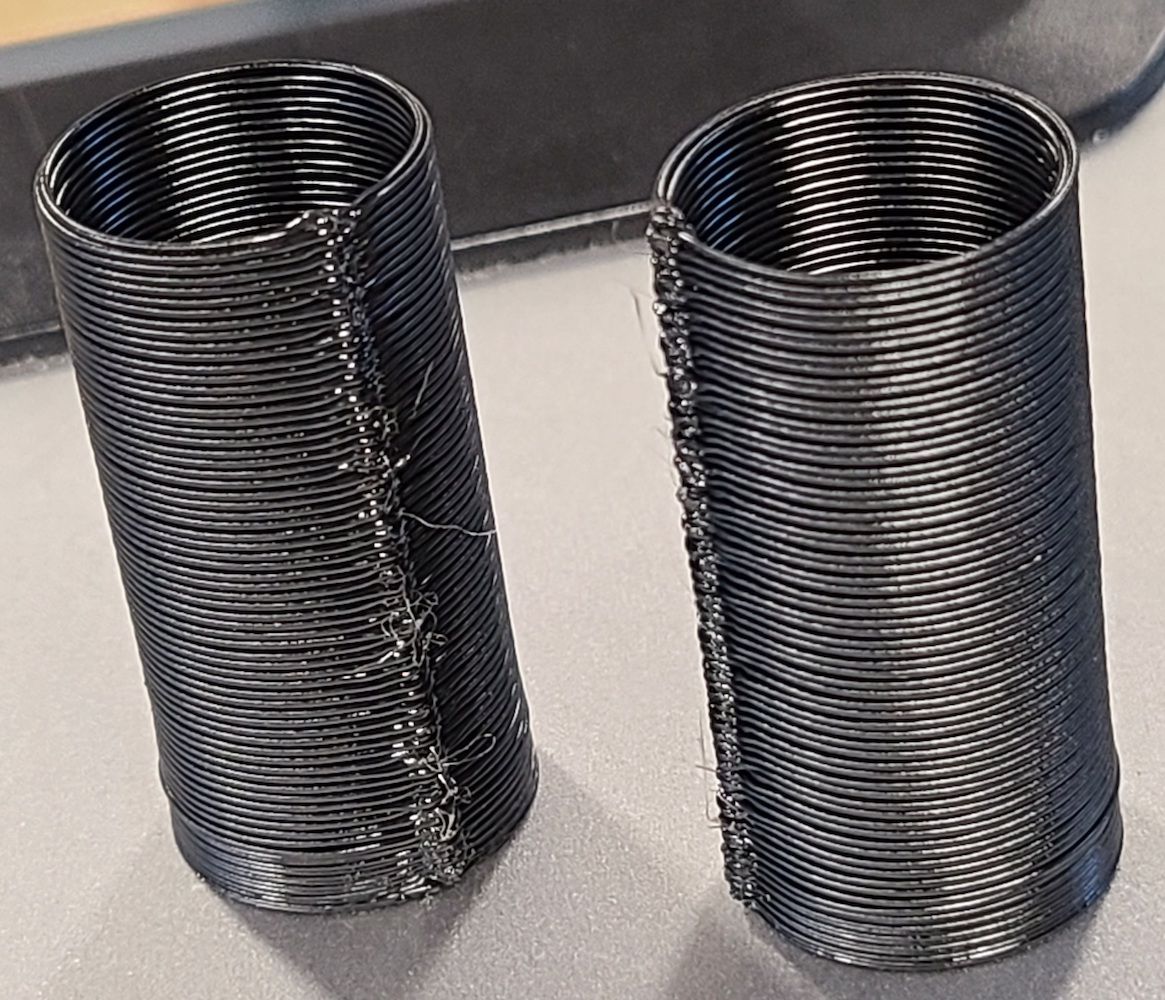

I printed in such a way as to have a top and bottom half. This was an experiment for a much larger project I have in mind that will not fit my printer and will have to be printed in two parts.

But my question was not about the vase it was more about the print head pausing when changing Z or going from one part to the other. I know I can minimize the affect by randomizing the 'start point' but in my case 'optimizing the start points' put them all above one another as such I was able to notice the pause when changing Z or part.

-

@brs You have jerk and acceleration for the Z axis set very low. You might try bumping them up by a lot to see if it helps.

I don't know how S3D handles vase mode, but if you're going to put together two parts printed in vase mode, I think it's a good idea to make sure that the two surfaces to be joined are both printed off the bed plate - i.e. the upper piece should be inverted.

-

@mrehorstdmd Inverted... very clever. Though it seems the two match up quite well. But like I said, the vase was just a test case. Inverting my subject project won't work.

I'll up the accel/jerk values and print some twin cylinders. -

Your extruder jerk and accel values are a bit low as well. Slow Z and E axis means a slow layer change, giving more time for ooze.

Have you tuned pressure advance yet?

-

@brs said in Help tune out "printer seam":

I upped the Jerk setting to...M566 X5000.00 Y5000.00 Z500.00 E120.00

and printed this...

[video here]

It's this line of blobs that I'm trying to tune out. Haven't yet increase Acceleration. -

@brs

Does this problem only appear now or did it happen after a change was made to the printer ?

For example, was the SD card changed ?It looks a little like overextrusion to me.

Has the correct flow rate already been determined ?

A pressure advance test could also benefit the printed image.Google Translate

----- Original Text -----Tritt dieses Problem erst jetzt auf oder passierte es nach einer Änderung am Drucker ?

Wurde zB die SD-Karte gewechselt ?Es sieht mir ein wenig nach Überextrusion aus.

Wurde die richtige Flussrate schon ermittelt ?

Ein Pressure Advance Test könnte dem Druckbild auch zur Gute kommen. -

@norder I'm still learning about pressure advance and have not yet implemented it. Thanks for the encouragement to do so.

This seems to be still initial tuning after conversion to Duet3D. It's a long and slow process as I'm still getting to know this technology.

I did just recently increase the extruder steps-per-mm after measuring the actual filament through put.

-

@brs

Meticulously setting up a printer can take a lot of time.

Actually, it practically never stops when 3D printing becomes a hobby.

For the little breaks...

Of course it could be the wrong settings.

It can also be due to a defective or very slow SD card.

It wasn't that long ago that someone had this exact problem.

If you have the opportunity, you should try a high-quality SD card or at least test the actual read/write values of your SD card if the error persists due to changed settings.You should always use another slicer as a reserve.

It can be very helpful when troubleshooting a problem like this.

If a version has a bug, you can switch to another slicer.

Simplify3D does not exactly stand out because of its update.

Is there now version 5, which was announced a long time ago ?Google Translate

----- Original Text -----Einen Drucker penibel genau einzustellen kann schon viel Zeit kosten.

Eigentlich hört es praktisch nie auf wenn das 3D drucken zum Hobby wird.

Zu den kleinen Pausen...

Klar kann es an den falschen Einstellungen liegen.

Es kann aber auch an einer defekten bzw sehr langsamen SD-Karte liegen.

Es ist noch gar nicht so lange her, da hatte jemand genau dieses Problem.

Wenn Du die Möglichkeit hast solltest Du mal eine hochwertige SD-Karte ausprobieren oder zumindest mal die tatsächlichen Schreib- Lesewerte Deiner SD-Karte testen, wenn der Fehler durch geänderte Einstellungen immer noch besteht.Einen anderen Slicer sollte man auch immer als Reserve nutzen.

Es kann sehr hilfreich sein bei einer Fehlersuche wie diese.

Hat eine Version mal einen Bug, dann kann man auf einen anderen Slicer ausweichen.

Simplify3D sticht ja nicht gerade durch seine Update hervor.

Gibt es mittlerweile Version 5, die vor langer Zeit mal angesagt wurde ? -

What kind of extruder is it?

Here is what I would start with

M566 X900.00 Y900.00 Z60.00 E2000 ; set maximum instantaneous (JERK) speed changes (mm/min) M203 X6000.00 Y6000.00 Z600.00 E6000 ; set maximum speeds (mm/min) M201 X500.00 Y500.00 Z200 E2500 ; set accelerations (mm/s^2)Note the changes to Z and E values

-

Thank you Phaedrux, I'll try those numbers or something close.

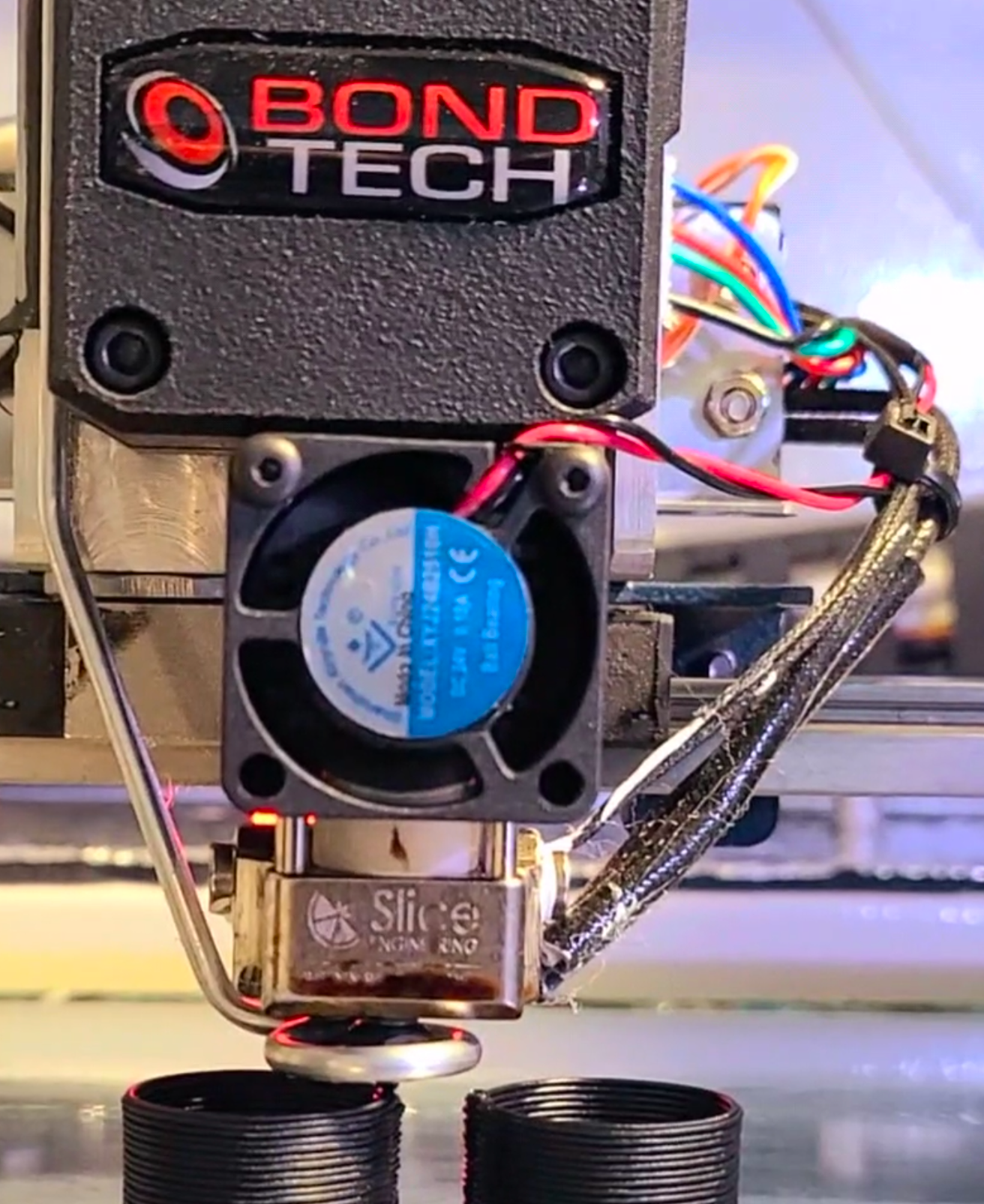

Here is a picture of my extruder/head. It currently has a .6mm nozzle.