1LC board "rare" peripheral support

-

Hi everyone,

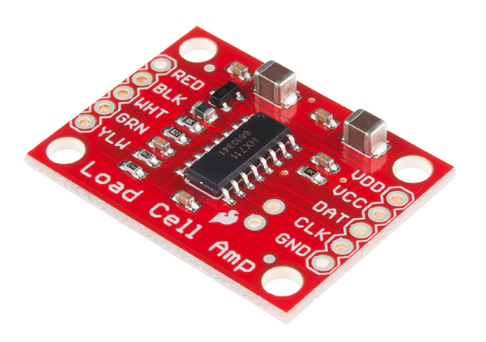

Do you know if it is possible to connect this amplifier for a load cell on a 1LC board?

https://www.sparkfun.com/products/13879?_ga=2.6962226.169585794.1656408252-1033354680.1649149432How? It's needed two addresable data pins and 3.3 to 5V power supply. Maybe it would be possible with IO3 pins (switch)?

I just need to pass-thru some GPIO from the cell load amplifier connected to 1LC, to mainboard (6HC+Raspberry PI SBC mode) where the pins are occupied by the ribbon cable connecting the two boards.At this moment it works attached to a second SBC apart from Duet main board where the readings are analised.

-

@dc42 Any hint? Do you think it would be possible.

Thx!

-

I raise this question again, as we still have this need.

Our aim is to be able to set up a load cell to measure the thrust/traction exerted by the plunger of a syringe extruder.

Can you think how to interface it with the 1LC board?

-

@marcossf said in 1LC board "rare" peripheral support:

I raise this question again, as we still have this need.

Please search this forum for the two words "strain gauge" - I bet you'll find some hints and ideas. With the alternate term "load cell", I had no obvious matches.

-

@marcossf said in 1LC board "rare" peripheral support:

I just need to pass-thru some GPIO from the cell load amplifier connected to 1LC, to mainboard (6HC+Raspberry PI SBC mode) where the pins are occupied by the ribbon cable connecting the two boards.

if you need to read the loadcell on the Pi and the pins are free (other than being covered by the ribbon cable) then you can connect only the required pins between the Duet and the Pi.

The pins is use are shown here:

https://docs.duet3d.com/Duet3D_hardware/Duet_3_family/Duet_3_Mainboard_6HC_Hardware_Overview#wiring-diagramreading the load cell with the 1LC would require a TWI input (and the code to drive it). The toolboard 1LC does not have an I2C/TWI interface allocated to any of the IO pins so it would require significant firmware work to extend the 1LC firmware to bit bang the protocol this uses and that would not be fast.

-

@t3p3tony There is attached the ribbon cable from the 6HC to the Raspberry PI, so the pins aren't reachables.

BUT, we need to interface the load cell amplifier to the 1LC board and deliver that sensor dato thru the same FD-Cambus it have, not directly to the 6HC or RPI pins.

I know it's a very uncommon scenario.

-

@t3p3tony I’m no expert, but would it be possible to put a Nano or ESP32 in between and then to mis-use one of the thermistor or BLTouch lines of the 1LC to move an analog reading over CAN? This, in turn, would be available to the SBC as an entry in the object model.

-

@infiniteloop @Marcossf yes you can stick some I2C -> analog board in the system. or:

- use a load cell board that outputs analog.

- use a SammyC21 with custom firmware to act as a tool board with this additional functionality.

-

@marcossf the HX711 does not use I2C, instead it uses a simple serial protocol. As such, it would be possible to write a new sensor type that uses one output pin and one input pin. The only available external output pin on the TOOL1LC is IO0_OUT; so if you are not using that pin already then the logical choice is to use IO0_IN and IO0_OUT. This new sensor type would need to be added to the TOOL1LC firmware.

BTW the HX711 is intended for use in weighing scales, so it has quite a low sample rate (10Hz or 80Hz). Would that be sufficient for your application?

-

@dc42 The frequency does not have to be high, it is simply a rheological control of the force needed to extrude/compress a given material.

We use this load cell at the moment with good results:

https://www.galoce.com/products/miniature-button-load-cell/GML679_Button_Force_Sensor_Load_Cell.htmlThe IO0.in is being used in the syringe empty end detection at this moment, but we could do without it or replace it with the IO3 endstop pins, so both IO0.in and IO0.out would become available.

So physically we could connect the amplifier board the way you suggest but I don't know is whether we will be able to modify the firmware of the 1LC board.