1LC boad extruder (syringe) loose steps

-

Hi everyone,

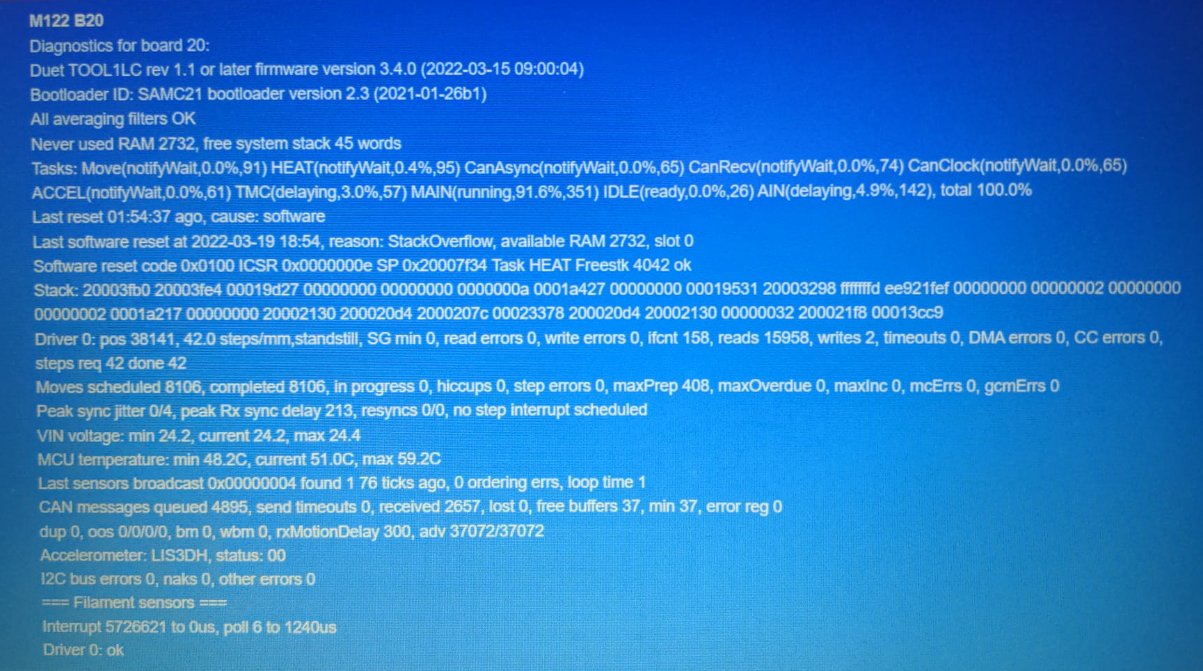

This capture shows a 1LC board diags which is connected to a stepper that moves a syringe. That gives you any hint of what could cause to sometimes loose steps?

The same gcode sometimes prints correctly without missing any extrusion and sometimes starts missing steps in some of them midle print. It always starts well, without losing steps, and after a few extrusions, it starts to lose steps, recovers and loses them again.

I have tried turning the current up and down, but the result is not the same.

If you move the extruder with the manual controls, never has step loss.

Another curious thing is that if the current is increased, the extrusion speeds change. The retraction slows down and the extrusion speeds up. Weird, isn't it?

Firmware 3.4.0 stable

Nema17 TR8x2 leadscrew motor 1.66A/phase

Set from 950 to 1200 mA current tried at 50mA intervals

1LC board 1.1Any hint what to seek at to troubleshoot it?

-

@marcossf Can't help directly as I've no experience of a syringe style extruder, but a few things that might help myself and other understand what is going on....

- Could you show a picture of the extruder.

- How do you know that you are missing steps (Can you hear the motors skipping or are you measuring what is happening)?

- If the motor current figures are in RMS you can almost certainly go to higher values than you have reported trying. In theory you can go to 1.414*1.66 = 2.34A even with the general rule of using 80% of the max that would still be 1870mA. Have you tried higher current settings?

It's hard to imagine how changing the motor current settings would slow down or increase the motor speeds unless you are skipping steps in both directions (and perhaps the pressure in the extrusion system is acting as some sort of spring?). Maybe a video of this happening would allow folks to provide more help?

-

@gloomyandy said in 1LC boad extruder (syringe) loose steps:

- Could you show a picture of the extruder.

Unfortunatelly we can disclose any image

- How do you know that you are missing steps (Can you hear the motors skipping or are you measuring what is happening)?

Exactly, the motor skipping steps doing their characteristic TAK-TAK noise

- If the motor current figures are in RMS you can almost certainly go to higher values than you have reported trying. In theory you can go to 1.414*1.66 = 2.34A even with the general rule of using 80% of the max that would still be 1870mA. Have you tried higher current settings?

According the motor specs the max is 1.68A/phase but they don't give info about RMS

It's hard to imagine how changing the motor current settings would slow down or increase the motor speeds unless you are skipping steps in both directions (and perhaps the pressure in the extrusion system is acting as some sort of spring?). Maybe a video of this happening would allow folks to provide more help?

Same we tought, it doesn't make sense. We think it could be the gel density which it need too much presure to get extruded out the nozzle

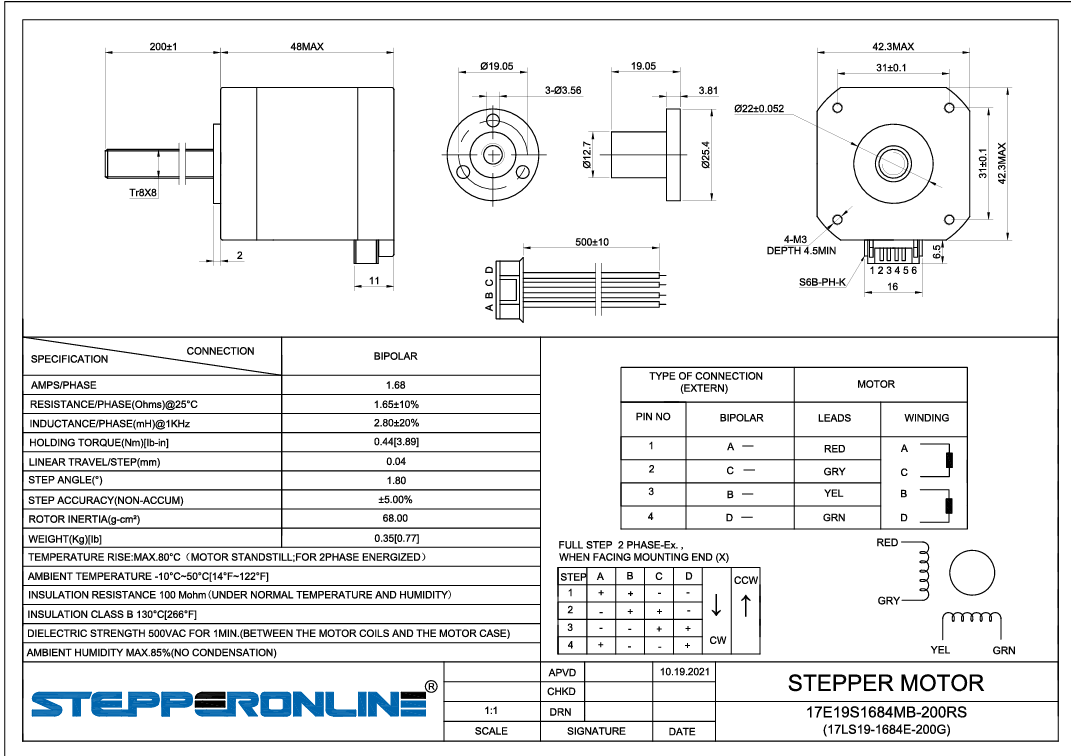

Motor specs are:

Step Angle: 1.8 deg

Holding Torque: 44Ncm(62.3oz.in)

Rated Current/phase: 1.68A

Phase Resistance: 1.65ohms

Voltage: 2.8V

Inductance: 3mH ± 20%(1KHz) - Could you show a picture of the extruder.

-

@marcossf Do the motors get hot at the currents you are running them at? If not I'd be tempted to increase the drive current. I think that most motor currents are given in RMS, but unfortunately it does vary. Perhaps you could contact whoever makes them and ask, or if you can provide details of the manufacturer others may be able to comment on if the current is likely to be RMS or Peak.

-

@gloomyandy The motor is the 17E19S1684MB-200RS from OMC-StepperOnline.

-

Did you know another TR8 leadscrew motor more powerfull than this?

-

@marcossf as @gloomyandy suggested already, I suggest you try increasing motor current above 1200mA.

If you do not need to move the syringe very fast, your best option may be to change to a motor with a lead that is smaller than the 8mm lead of your current motor, for example https://www.omc-stepperonline.com/nema-17-external-48mm-stack-1-68a-lead-2mm-0-07874-length-200mm-17e19s1684af-200rs.

-

@dc42 Thanks David anb @gloomyandy

In some situations the syringe needs to get 20mm/sec linear speed. I don't know if we can achieve that with a 2mm lead, we would have to give it a try.

We are testing with higher currents (1350mA so far) but still having a few step losses in a batch print.

W e have concluded that the problem we have is due to the density of the material and the back pressure generated at the nozzle (1mm). With more liquefied materials we have no problems.

-

@marcossf if back pressure is the problem then you need a higher torque motor or a finer leadscrew. The calculator at https://www.reprapfirmware.org/emf.html suggests that with 24V supply, 20mm/sec would be achievable using the motor I suggested without loss of torque, if I have entered the data correctly.

-

@dc42 Fine. We will bought some 2mm lead motors for testing it and benchmarking it.