Unknown Print Error

-

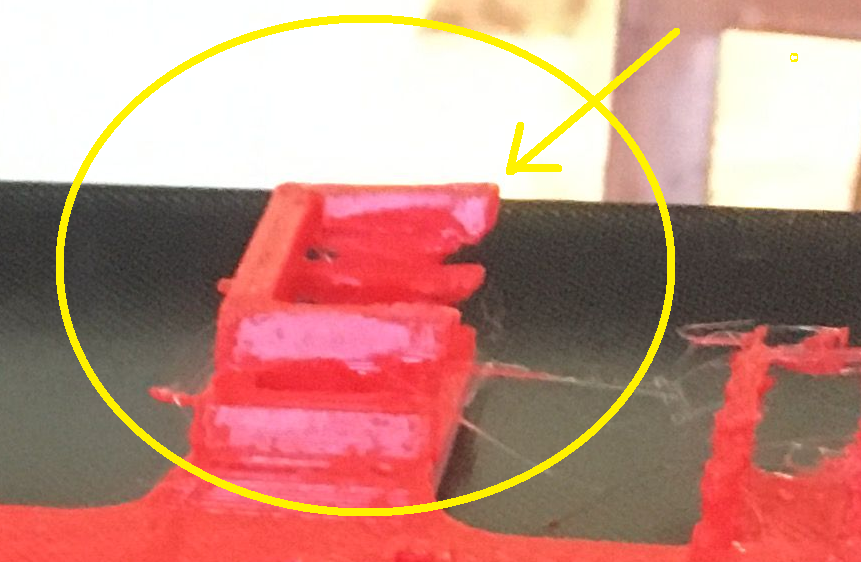

Your prints looks like it has curled upwards at some locations and that your nozzle has possibly collided with printed part at those locations causing a layer shift. Also your prints look "melted" to me. Possibly not enough cooling or too high extruder temperature for the material.

If you are using some version of Ender printer, I suggest using slicing profiles meant for that specific printer.

-

@visionary When you mean the part is curling at some spots, where do you mean?

-

-

@visionary That is not corner coming up. That is the issue I am talking about: the head somehow moves up by 5 mm and starts printing there. So what you are talking about is the top part of the print being suspended mid-air due to this problem.

-

Does it hit something or do the motors just randomly lift z axis up about 5 mm? you can check G-code for high Z-axis commands with some text editor apps.

-

@visionary I am not sure. And I misspoke...the Y axis moves back

-

Then it is likely that nozzle hit your print for some reason. Your stepper motors missed

steps and countinued at another Y-location. -

@visionary I have had this issue multiple times now. Would the Z-Offset cause this, as I also hear a scraping noise when my printer is printer, which I now realize is probably the nozzle scraping against the part. And if so, how do I accurately calculate the Z-Offset (I already did the Docs say and used baby stepping).

-

@tratoon said in Unknown Print Error:

@visionary I have had this issue multiple times now. Would the Z-Offset cause this, as I also hear a scraping noise when my printer is printer, which I now realize is probably the nozzle scraping against the part. And if so, how do I accurately calculate the Z-Offset (I already did the Docs say and used baby stepping).

Best practice would be to move z-endstop to correct height and then level your bed and not use any z-offset (though you may have to use some with small layer height prints). Usually you can get correct z-height by using a paper and finding a height that just barely allows paper to slide freely between nozzle and bed.

Setting Z-offset cannot cause problem seen in your prints because it affects only first few layers, because FDM-printing is self correcting process. I'd say your problem is related to temperatures or overrall extrusion amount.

-

@visionary uncomment G29 S1 from your start gcode, could be that when probed it sensed some bed clip or so and thinks that the bed is curled up and now trying to compensate. How does your height map look like btw?!

-

@visionary If it is a temperature problem, what is the best temperature for PLA (for bed and nozzle) and if it is a extrusion issue, how do I fix it?

-

@kr15_uk Bed is really level, less that 0.025mm deviations

-

215 C (or 200-220 C) for hotend and 50 C (or 0- 60 C) for bed, but those may vary depending on exact position of thermistors (sometimes thermistor doesn't make the best possible contact to what it is suppose to measure). If your bed's actual temperature is higher than about 60 C the PLA will be very soft that should be usually avoided. Wrong parameters in your printers config/software can cause your printer to show and use incorrect temperature values.

-

@visionary And how would I know if it is an extrusion issue?

-

It might be hard to see from the print. One thing that can resolve overextrusion issues is to recalibrate E-steps.

Tip: Use these guides to determine printing quality issues:

https://www.simplify3d.com/support/print-quality-troubleshooting/

https://all3dp.com/2/3d-print-quality-12-tips-on-how-to-improve-it/ -

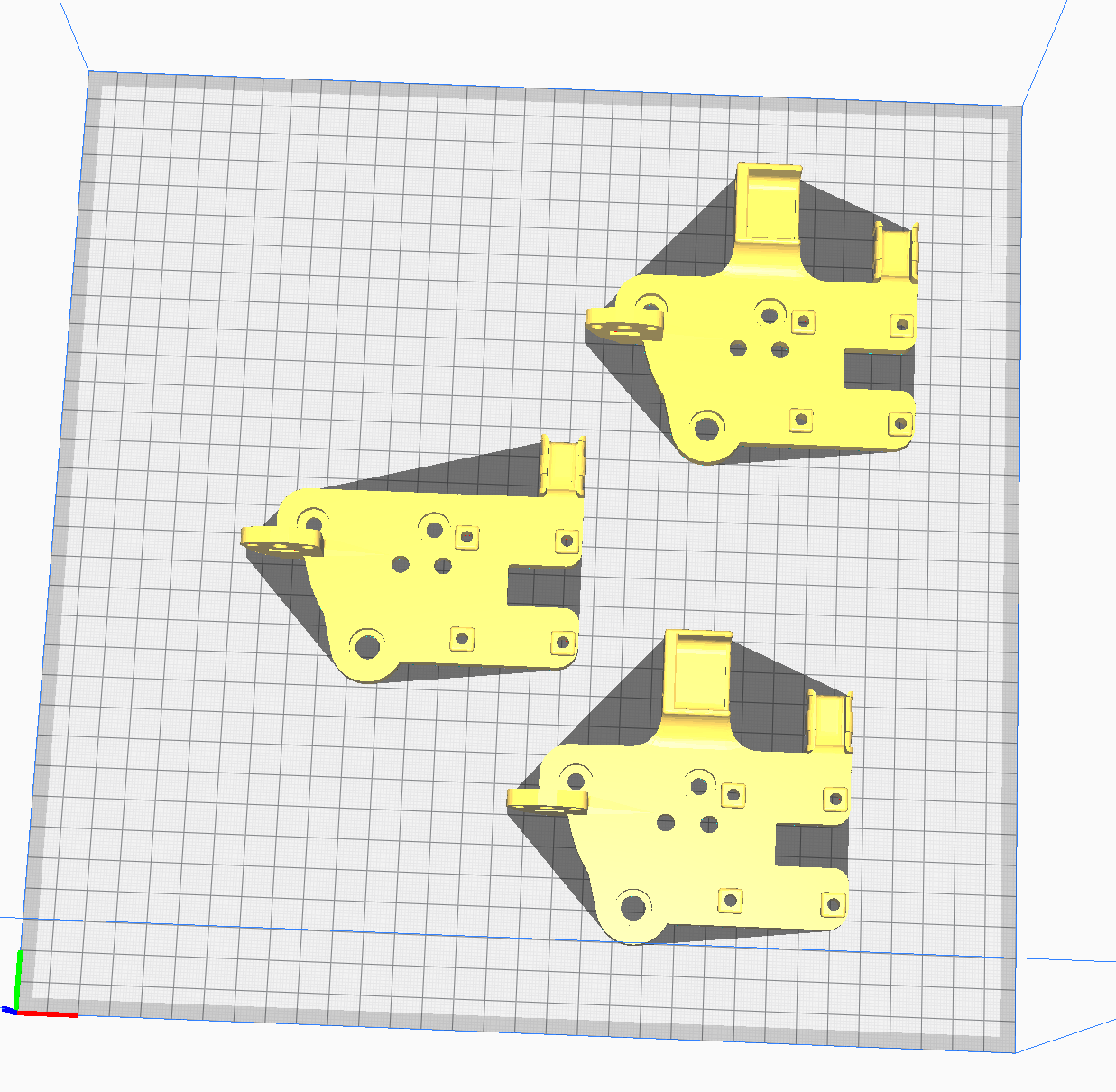

@tratoon can you post a screenshot of a stl itself, could help better understand what it’s suppose to look like

-

-

Some comments -

Setting z-offset. I'm and engineer and don't like the "paper test" because it assumes the sheet of paper is "some thickness" and that all pieces of paper are the same thickness, and that the edges don't get bent or get contaminated by a bit of hot plastic. I think a much better result is obtained by purchasing a set of "feeler gauges" something like this: https://www.amazon.com/Stainless-Feeler-Imperial-Measuring-0-02-1-00/dp/B08GLN7K1R. Get a long set, not the tiny ones for spark plugs. I set the Zoffset by heating up the bed and hot end, homing the printer (z axis is critical) and selecting the tool (send a T0 command if you have only one tool). Now, use the DWC move commands to bring the nozzle close to the bed, moving in small increments when you get close. Keep getting closer until the 0.2mm gauge slides in with a no (or maybe slight) dragging, and the 0.25mm gauge doesn't slide under (or needs to be shoved hard to fit). Now the nozzle is where you want Z=0.2 to be for this tool. The DWC will tell you what the current Z is for this tool. Then Send a

G10 P0 Z<some number> ; P0 means tool 0When you change the <some number>, notice that the Z in the DWC changes (note the nozzle does not move at this stage). Change <some number> until the Z in DWC says 0.2mm. This is the z offset you need and you can have confidence that a precision stainless steel gives you and that paper never will.

Add the G10 command to your config.g, or save it using an M500.

I always us the .2mm gauge because I always use a .2mm first layer, but you can really use any two gauges if they are flexible and there are two that are 0.05mm different in thickness.

But enough of my peeve and on to your core problem. If the parts are not being knocked off the bed (they look like they are not), then I think it's one of three things -

-

Belt slipping. if the error is always an offset of 2mm (or an increment of 2mm because that's the pitch of teeth on a GT2 belt), then it's almost certainly the belt jumping one tooth. Check the belt tension and also look for something hitting something during printing. With all the loose plastic in your pictures, small mis-print might have started a glop of plastic that hardened up and hit something.

-

Gear on stepper slipping on the shaft. If the shift is not an increment of 2mm, than one of two thing might be happening.

2A. If the little grub screw holding the gear to the stepper is not tight, when something hits something, the gear might be turning on the shaft rather than the belt slipping.

2B. A shift not in increments of 2mm can be the result of a motor skipping steps. This can be cause by a physical crash, a setting too high in acceleration or jerk, a sticky bearing, or maybe even a bad motor. You can try printing a single part and see if it fails at the same place every time, which implies something related to the specific gcode steps when the failure occurs.

Don't ask me how I learned about these possibilities...

-

-

@mikeabuilder The part fails at the same spot every single time. And also, I am assuming that you want a gap up 0.2mm for a 0.4mm nozzle, so what gap would you want for a 0.6mm nozzle. And also, do I just change <some number> to random numbers until I get 0.2 in the DWC?

-

Also what is the difference in using a G10 command rather than changing the Z-Offset in the G31 P500 X-41 Y-2 Z1.7 command? And if I were to use the G10 command, would I change the G31's offset to 0, then move the bed up until it touches the nozzle and set that as Z0, then move the bed down until the .2mm gauge fits properly and set the Z position in the DWC at that time as the <some number> in the G10? If this is not how I'm supposed to do it, would you mind explaining it in more depth?