any way to pass parameters to start.g?

-

Would be nice on the heated chamber set chamber to 80C and not start printing untill upto temperature

-

@owend just some way to pass temperatures from a slicer into start.g without needing another script. I guess I could go about setting global variables or look into RRF based filament management.

-

@oliof We are doing this through the selected filament. Our slicer profile doesn't include any temps in the output gCode. Instead, each filament config contains something like the following:

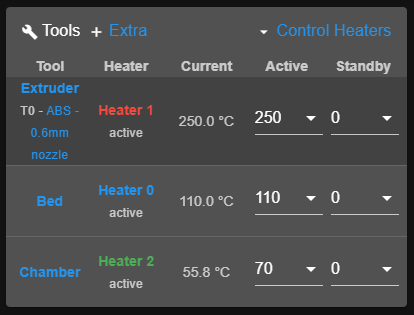

set global.bedTemp= 110 ; Defines build plate temperature set global.chamberTemp= 70 ; Defines chamber temperature set global.filamentTemp= 250 ; Defines extrusion temperatureAnd then start.g handles it through M703.

;========================================================================================== ;== Configure Filament ==================================================================== M703 ; Load selected filament settings ;========================================================================================== ;== Enables Heat / Stabilizes ============================================================= M140 S{global.bedTemp} R0 ; Enable build plate heater G10 P0 S{global.filamentTemp} R0 ; Enable hot end heater M116 ; Wait for temps to stabilize M141 S{global.chamberTemp} ; Enable chamber heater -

@oliof said in any way to pass parameters to start.g?:

I guess I could go about setting global variables or look into RRF based filament management.

That's how I do it.

Though I don't use start.g since that happens before any slicer code and it is possible, depending on the specific slicer and settings, that the slicer code could conflict with the start.g code.

I use the capability to specify in the slicer code to execute at certain times, such as the start and end of the print.

Frederick

-

@oozebot how do you select the filament though?

-

@oliof I believe one has to be initially selected in DWC? Maybe not if you don't have any defined.. Regardless, after creating a filament profile(s), there is the option to select the active filament in DWC here:

You can see that we also adding nozzle size to the filament profiles as we can move a .4mm nozzle faster than .6mm and pressure advance needed to be tweaked between them.

Once I finally wrapped my head around using Filaments and start.g, it's changed a lot of how we now operate. We use the Slicer to output nothing but the movement/extrusion codes (and also firmware retraction codes). Everything else is stored in the various filament profiles. What this allows is the same model to be printed with various filaments.. that sounds ambitious, but it works well if you spend the time to baseline your standard printing speeds. If a certain filament can only print at 80% of your baseline speed, that can also be compensated with M220 S80.

-

@oliof said in any way to pass parameters to start.g?:

how do you select the filament though?

Via the DWC.

As part of my "print start" code I also have what I call "sanity checks", which is code that verifies that a filament has been selected, that the global variables have been populated with reasonable values, etc.

Frederick

-

@oliof said in any way to pass parameters to start.g?:

how do you select the filament though?

DWC stores the last filament(s) in filaments.csv

I use that in conjunction with a global variable in config.g

In my filaments config.g I have cold extrude temps, retraction etc that's specific to the filament.

I don't set print temp here but you could.

All my filament load and unload files point to a central load/unload and I also have a "pre-heat-current-filament.g" file.In my slicer start code I set the global variable for filament.

If that doesn't match what's on the machine then it automatically does a filament change.As mentioned, the problem as I see it with doing everything in start.g is that anything a user does in the slicer will over-ride it.

Not such a deal for a single user, but if I were selling machines I would expect problems.I'm hoping when we get arrays that I can simplify the filaments to maybe a single file.

It would be great if we could read a csv file into an array or perform a sort of VLookup search. -

@owend said in any way to pass parameters to start.g?:

DWC stores the last filament(s) in filaments.csv

I use that in conjunction with a global variable in config.gThere is a unique config.g file for each created filament entry and executing M703 runs the file for the current filament.

That has proven to be sufficient for my needs.

What are you doing different that needs the filaments.csv file?

Thanks much.

Frederick

-

@fcwilt

I just populate my global variable at startup in config.g based on what RRF/DWC loads from filaments.csv

I also call M703 in config.g if a filament was loaded.If I slice using a different filament the changed global prompts the necessary new settings and load/unload

The individual config.g in the filaments directory I use for unique settings which are of course applied when M703 is called.

-

@owend said in any way to pass parameters to start.g?:

@fcwilt

I just populate my global variable at startup in config.g based on what RRF/DWC loads from filaments.csv

I also call M703 in config.g if a filament was loaded.If I slice using a different filament the changed global prompts the necessary new settings and load/unload

The individual config.g in the filaments directory I use for unique settings which are of course applied when M703 is called.

Thanks for the feedback but I cannot visualize what you are doing.

You mentioned that you do not set print temps using the filament specific config.g file. If you don't do it there where do you do it?

Thanks.

Frederick

-

@fcwilt

In my config.g I have;load config for filament if move.extruders[state.currentTool].filament="" echo "No filament loaded. Cold extrude & retract set to defaults" M302 S190 R110 ; Allow extrusion starting from 190°C and retractions already from 110°C (defaults) set global.LoadedFilament="No_Filament" else set global.LoadedFilament=move.extruders[state.currentTool].filament ; set the variable to the currently loaded filament echo "Loading config for " ^ global.LoadedFilament ^ " filament" M703 ; if a filament is loaded, set all the heats and speeds for it by loading config.gI set my print temp in the slicer start code.

Most slicers will put a temp in the start code if you don't , so if you rely on start.g it'll possibly be over written.set global.minProbeX = {first_layer_print_min[0]} set global.maxProbeX = {first_layer_print_max[0]} set global.minProbeY = {first_layer_print_min[1]} set global.maxProbeY = {first_layer_print_max[1]} T[current_extruder] ; set global.LoadedFilament="[filament_type]" ; set the global filament name variable M98 P"0:/macros/filament/check-filament-type.g" M703 ; load config file for [filament_type] M568 P[current_extruder] R{"{heat.coldExtrudeTemperature+5}"} S[first_layer_temperature_0] ; (set standby and active temperatures for active tool. Standby is 5 degrees above cold extrude tempCheck filament type just ensures that what I've sliced with matches what is loaded.

I'm not near my computer but I have it all in a GitHub repository

There's probably less complicated and/or better ways.

I'm sure E=MC2 started out three pages long

-

-

@owend said in any way to pass parameters to start.g?:

Most slicers will put a temp in the start code if you don't , so if you rely on start.g it'll possibly be over written.

JOOC what slicer do you use?

When faced with the possibility of slicer generated code conflicting with my code I did a number of tests for the slicers I have (Simplify3D, Prusa, Cura, ideaMaker) and found ways to insure there were no conflicts - so I am able to set the temp specified by each filament config.g file in my print start code which is invoked by the slicer using M98 commands.

For example from ideaMaker 4.2.3 - notice there is no slicer generated temperature setting code - so it can be done in print_begin.g or print_filament_start.g which is my code:

M221 T0 S90.00 M98 P"print_begin.g" M98 P"print_filament_start.g" M83 M106 S0 M82 M98 P"print_layer_change.g" M83Frederick

-

@fcwilt

I used to use Cura

I seem to remember it trying to add temperatures if you didn't have one on its start code.

I now mainly use superslicer.

I can't recall if it does or not, but as I set a temperature in the slicer it doesn't bother me.

I tend to tweak sliced temps based on the size of the model.

I understand your approach gives you slicer independence if you overcome the slicer interfering.