Duet3 6HC Openpnp

-

Hi I have Charmhigh 36VA pnp machine that I have been converting to Openpnp. I initially flashed smoothie on the stock machine board but suffering intermittent comm issues and poor overall machine performance. I have just ordered a Duet 6HC board to replace the stock board that should arrive in a week.

I am hoping to get a head start on porting the config from smoothie to Reprap3.3b1. I have all the machine specific parameters, but at a loss as how to correctly apply them in a format acceptable to Reprap config. I have been reviewing openpnp dozuki but it looks to be incomplete.

I have two specific questions relating to setting up the axis config.

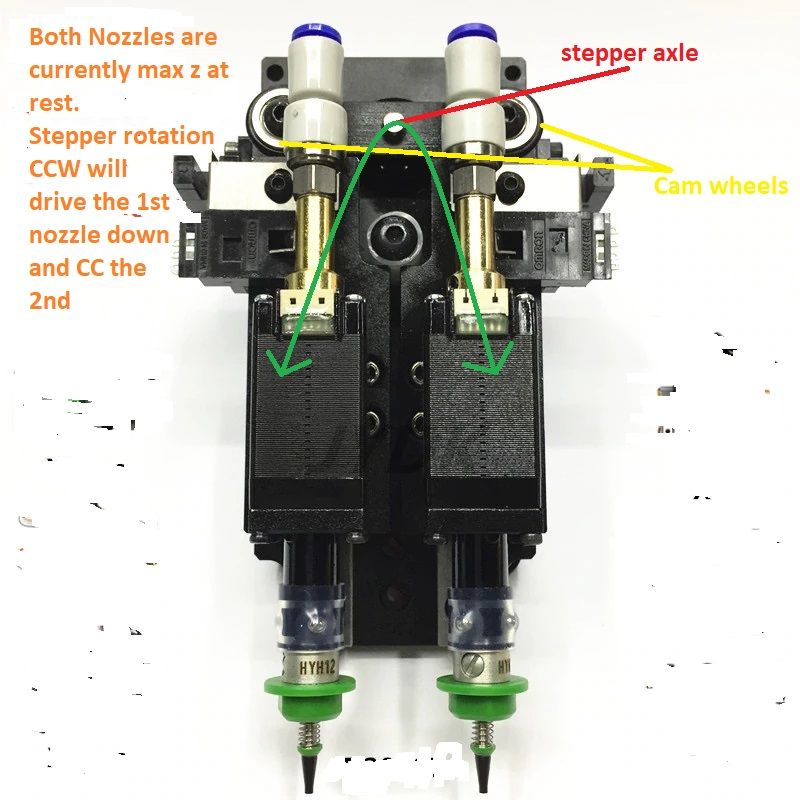

1, The machine head has two nozzles controlled by a single Z motor in a CAM or 'seesaw' arrangement

dual nozzle CAM . How can I set this up correclty within RepRap?

2. The machine has a 6th motor, (5 axis, single motor each axis) for reel tape uptake for the drag feeder arrangement. How would I go about setting this up?Thanks for all and any help.

-

@wayneosdias, thanks for choosing Duet 3.

-

What activates the see saw mechanism? If it's one or two solenoids then you can drive them from the heater or fan outputs on the MB6HC. Configure them as GpOut ports (see the M950 command with P parameter) and have OpenPnP send M42 commands to switch them.

-

I haven't used a PnP machine so I don't know exactly what you are asking. Is the amount of motor movement needed known, or is the intention to apply a low force to tension the tape?

-

-

@wayneosdias Thanks for responding;

1, I will try to get a video to better demonstrate, but in a nutshell; Two nozzles are at either end of the of the cam and at the center a stepper motor. At rest/homed both nozzles are at the Z max height and suspended this way by springs supporting against gravity. Once the stepper is activated, CCW the 1st nozzle is pushed down and the 2nd nozzle is suspended by the spring. Conversely when the stepper is activated CC the 2nd nozzle is driven down and the 1st nozzle is suspended at max z by the spring.

I attached a crude pic that may help.

2, Motor movement is known. A single component pick will require and single movement of known amount and then rest. Constant tension is not needed. The known movement will be known, but not constant and will depend on the ic/component tape.

-

@wayneosdias thanks. In that case, both the nozzle selection stepper motor and the tape motor can be configured as additional axes using the M584 command in config.g, and OpenPnP can control them using G0 or G1 commands.