z probe help if possible

-

Hi all,

i am trying to figure out this z probe. I installed black on Io in, Blue on Ground, Brown i ran to 24v. I soldered BAT85 with black facing resistor. just trying to get the config right.

image url)

image url); General preferences G90 ; Send absolute coordinates... M83 ; ...but relative extruder moves ; Network M550 P"duet3" ; Set machine name M552 S1 ; Enable network ;*** Access point is configured manually via M587 M586 P0 S1 ; Enable HTTP M586 P1 S0 ; Disable FTP M586 P2 S0 ; Disable Telnet M575 P1 S1 B57600 ; Panel Due ; Printer geometry M669 K1 ; Select CoreXY mode M208 X0:330 Y0:285.75 Z0:350 ; Axis Limits M564 H0 ; allow unhomed movement ;------- drives from top--------------------------------------------------- ; B -------+------ A ; | P.02 | P.03 | ; -------+------- Z-Drives ; | P0.1 | P0.4 | ; -------+------- ; Front ; Drive Mappings M569 P0.0 S1 V0 ; Drive 0: E Axis M569 P0.1 S1 V0 ; Drive 1: Z-LeftFront Axis M569 P0.2 S0 V0 ; Drive 2: Z-LeftRear Axis M569 P0.3 S1 V0 ; Drive 3: Z-RightRear Axis M569 P0.4 S0 V0 ; Drive 4: Z-RightFront Axis M569 P1.0 S1 V0 ; Drive 5: Expansion: B motor (X-axis) M569 P1.1 S1 V0 ; Drive 6: Expansion: A motor (Y-axis) ; Motor remapping for Quad Z and axis Limits M584 X1.0 Y1.1 Z0.1:0.2:0.3:0.4 E0.0 ; Motor mapping M671 X-76.2:-76.2:406.4:406.4 Y0:374.65:374.65:0 S20 ; Z leadscrews positions Left Front - Let Rear - Right Rear - Right Front ; Microstepping and Speed M350 X32 Y32 E16 Z16 I1 ; Configure microstepping with interpolation M92 X200.00 Y200.00 Z200.00 E400.00 ; Set steps per mm 1.8 motors ; Speeds, Acceleration and Jerk M566 X400.00 Y400.00 Z25.00 E600.00 P1 ; Set maximum instantaneous speed changes (mm/min) M203 X12000.00 Y12000.00 Z1000.00 E3600.00 ; Set maximum speeds (mm/min) M201 X3000.00 Y3000.00 Z100.00 E3600.00 ; Set accelerations (mm/s^2) ; Motor currents M906 X1200.00 Y1200.00 Z1200.00 E700.00 I60 ; Set motor currents (mA) and motor idle factor in percent M84 S600 ; Set idle timeout ; Endstops for each Axis M574 X2 S1 P"io0.in" ; Set X endstop controlled by switch M574 Y2 S1 P"io1.in" ; Set Y endstop controlled by switch ; Z-Probe M558 P8 C"io3.in" H5 F120 T60000 ; set Z probe type to unmodulated and the dive height + speeds G31 P500 X0 Y0 Z2.5 ; set Z probe trigger value, offset and trigger height M557 X15:215 Y15:195 S20 ; define mesh grid ; Stallgaurd Sensitivy (maybe use to pause print after crash) M915 X S2 F0 H200 R0 ; Set X axis Sensitivity 1.8 motors M915 Y S2 F0 H200 R0 ; Set y axis Sensitivity 1.8 motors ; Input Shaper and Accelerometer ;M955 P0 C"io4.out+io4.in" ;M593 F46.75 S0.2 ;M593 F19 P4 S0.3 ; experimental ; Z Probe Offset (Probe behind Afterburner) G31 P500 X0 Y0 Z1.5 ; Heaters M308 S0 P"temp_0" Y"thermistor" A"Bed" T100000 B4138 ; configure sensor 0 as thermistor on pin temp0 M950 H0 C"out_0" T0 ; create bed heater output on out0 and map it to sensor 0 M307 H0 A350 C139 D5.5 B0 ; set model parameters for heater 1 and use PID mode M140 H0 ; map heated bed to heater 0 M143 H0 S120 ; set temperature limit for heater 0 to 120C M308 S1 P"temp_1" Y"thermistor" A"Hotend" T100000 B4725 C7.06e-8 ; configure sensor 1 as thermistor on pin temp1 M950 H1 C"out_1" T1 ; create nozzle heater output on out1 and map it to sensor 1 M307 H1 B0 R2.436 C191.9 D3.44 S1.00 V24.1 ; disable bang-bang mode for heater and set PWM limit M143 H1 S280 ; set temperature limit for heater 1 to 280C ; Fans M950 F0 C"out7" Q500 ; Parts cooling create fan 0 on pin out7 and set its frequency M106 P0 S0 H-1 M950 F1 C"out8" Q500 ; Extruder create fan 1 on pin out8 and set its frequency M106 P1 T45 H1 ; Fans Electronic compartment & Exhaust ;M950 F1 C"out3" Q100 ; Creates Case Fan 1 ;M106 P1 T40 S150 H0 ; Case Fan 1 Settings (Turns on at 60°C tool temp) at low speed ;M950 F2 C"out4" Q100 ; Creates Case Fan 2 ;M106 P2 T40 S150 H0 ; Case Fan 2 Settings (Turns on at 60°C tool temp) at low speed ;M950 F5 C"out7" Q100 ; Creates Case Fan 2 ;M106 P5 T95 S50 H0 ; Exhaust fan ; Filament Runout sensor ;M950 J4 C"io5.in" ; Input 4 filament sensor ;M581 P1 T2 S1 R1 ; Filament Sensor P1 triggers inactive-to-active edge (S1) tigger2.g (T2) only when printing (R1) ;M591 D0 P1 C"io5.in" S1 ; Filament Sensor ; Tools M563 P0 D0 H1 F0 G10 P0 X0 Y0 Z0 ; Set tool 0 axis offsets G10 P0 R0 S0 ; Set initial tool 0 active and standby temperatures to 0C T0 -

Hi,

What Duet hardware are you using? What version of the firmware?

What is the part number of the "z probe"? I cannot make it out.

Why did you add that diode?

Thanks.

Frederick

-

@frnknstn said in z probe help if possible:

M558 P8 C"io3.in" H5 F120 T60000

Hi again

With the bat diode you would need a pullup as far as I can remember.Try this:

M558 P8 C"^io3.in" H5 F120 T60000 -

I don't know what you mean by "facing resistor"--> Facing probe?

" The BAT85 diode should always be wired with the black band toward the probe, not toward the MCU."Now, the input of the Duet 3 board is 30 v tolerant so you wouldn't really need the diode. But I leave that to other to answer as I don't want your board to burn if I'm wrong

It should work with the diode and a pullup.

Test the probe first just by connecting power to it and see that the led turn off and on when you put metal near it.

-

Board: Duet 3 MB6HC (MB6HC)

DSF Version: 3.4-b6

Firmware: RepRapFirmware for Duet 3 MB6HC 3.4.0beta6 (2021-11-06)The BAT85, this is from the voron 2.4 build. Its on the BOM, and some of the sights to purchase this z probe are selling it with the BAT85 preinstalled. This is a PL-08N2 probe.

-

@frnknstn The way i have it now it LED is on at all times and when i get close to metal it does go off

-

@frnknstn Sounds good to me

-

@gixxerfast Should i do the pull up if it is signaling as is?

-

@frnknstn Yes, that's how I remember I had it working too, before switching to the Klicky probe.

You can always check it before you try to use it for real by the "near to metal" thing

-

@gixxerfast cool, ill test it out. I will be switching to Klicky soon to as soon as this beast is up and running properly.

-

@frnknstn said in z probe help if possible:

@gixxerfast Should i do the pull up if it is signaling as is?

The Duet 3 hardware has built-in pullups - you do not use the ^ character.

I would remove the diode.

Frederick

-

@fcwilt no problem ill remove it and see.

-

@frnknstn removed and removed. LED on probe is on and metal near it shuts it off. Im assuming this is good. Now i just have to get the config right. thank you guys for your help

-

EDIT: Fantastic, I learned a new thing here. No explicit pullups required with the Duet 3. Changed all my configs now.

I need to go through my config I'm using '^' pullups everywhere

So, I don't need to explicitly enable internal pullups on the Duet 3 hardware?

For example when I have a ground to in switch endstop?

-

@gixxerfast man, I never thought I would get this much help at setting up my printer and learning what's going on. I am very appreciative

-

@frnknstn now if i can get help with my config i would love it.

-

@gixxerfast said in z probe help if possible:

So, I don't need to explicitly enable internal pullups on the Duet 3 hardware?

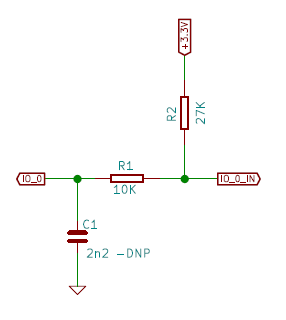

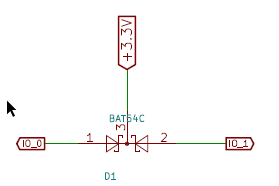

Here are the schematics for the inputs 0 to 8. The first image shows the basic circuit. The second shows the input protection provide.

You can find the Duet 3 6HC schematics here:

Frederick

-

@frnknstn said in z probe help if possible:

@frnknstn now if i can get help with my config i would love it.

What kind of help do you need?

Frederick

-

@fcwilt So, when i home all for example, X homes properly, Y homes properly, Z does everything until it gets to the probe inputs. It goes to my first probe point then instead of going down to test, it goes up real slow and dont stop unless i trigger the probe.

-

@frnknstn I think you need to post your latest config.g, homeall.g and homez.g