3HC Extruder missing in action

-

@kcress

the only idea I have is that temperature sensor and heater must be on the same board https://forum.duet3d.com/topic/25454/hardware-tool-board/3 Maybe the extruder must be on the same board also??Probably this:

https://duet3d.dozuki.com/Wiki/Duet_3_firmware_configuration_limitations

"Filament monitors must be connected to the same board as the corresponding extruder motor. " -

@joergs5 Thanks.

Trying to get my head around why that would cause the extruder to not show up at all. I could see the filament-out sensor not working correctly.

I commented out the existence of the filament-out sensor (M591) with no improvement.

-

@kcress maybe the 3HC CAN address is wrong, please see https://duet3d.dozuki.com/Wiki/CAN_connection#Section_Setting_CAN_addresses

You can make a M122 B1 to check whether the address is 1.

To check whether there are errors in config.g, you can call M98 P"config.g" -

@joergs5 I was just going to ask how to tell if the 3HC was thinking and was there an M122 for extra boards. You must be clairvoyant.

Seems to be there..

Elsewhere I listed my drives so I thought they were sort of approved selections but maybe not. I list them below again.

M122 B1 Diagnostics for board 1: Duet EXP3HC firmware version 3.3 (2021-06-15 16:12:41) Bootloader ID: SAME5x bootloader version 2.3 (2021-01-26b1) Never used RAM 159104, free system stack 4378 words Tasks: Move(notifyWait,0.0%,160) HEAT(delaying,0.1%,104) CanAsync(notifyWait,0.0%,69) CanRecv(notifyWait,0.0%,82) CanClock(notifyWait,0.0%,71) TMC(notifyWait,44.8%,63) MAIN(running,46.9%,438) IDLE(ready,0.0%,39) AIN(delaying,8.2%,263), total 100.0% Last reset 05:40:57 ago, cause: software Last software reset data not available Driver 0: position 0, 420.0 steps/mm, standstill, reads 62464, writes 16 timeouts 0, SG min/max 0/0, steps req 0 done 0 Driver 1: position 0, 80.0 steps/mm, standstill, reads 62470, writes 11 timeouts 0, SG min/max 0/0, steps req 0 done 0 Driver 2: position 0, 80.0 steps/mm, standstill, reads 62470, writes 11 timeouts 0, SG min/max 0/0, steps req 0 done 0 Moves scheduled 0, completed 0, in progress 0, hiccups 0, step errors 0, maxPrep 0, maxOverdue 0, maxInc 0, mcErrs 0, gcmErrs 0 Peak sync jitter -7/7, peak Rx sync delay 182, resyncs 0/0, no step interrupt scheduled VIN: 24.3V, V12: 12.2V MCU temperature: min 32.6C, current 33.2C, max 33.9C Ticks since heat task active 124, ADC conversions started 20457198, completed 20457197, timed out 0, errs 0 Last sensors broadcast 0x00000000 found 0 129 ticks ago, loop time 0 CAN messages queued 30, send timeouts 0, received 184124, lost 0, free buffers 37, min 37, error reg 0 dup 0, oos 0/0/0/0, bm 0, wbm 0, rxMotionDelay 06HC:

Drive 0 => X (P0.0)

Drive 1 => Y (P0.1)

Drive 2 => Z1 (P0.2)

Drive 3 => Z2 (P0.3)

Drive 4 => Z3 (P0.4)

Drive 5 => Z4 (P0.5)3HC:

Drive 0 => E0 (P1.0) -

@kcress What do mean when you say the extruder is grayed out in DWC? looking at the dashboard page, in the top left window, do you see the extruder drive and its position? Further down the page, under extrusion control, do you see "E0" listed? Or are you referring to the extrude and retract buttons? If it's just those buttons, then the reason they are greyed out is because you have to have an active tool and it has to be heated before extrusion is allowed unless you send M302 to set or disable the temperature restrictions.

-

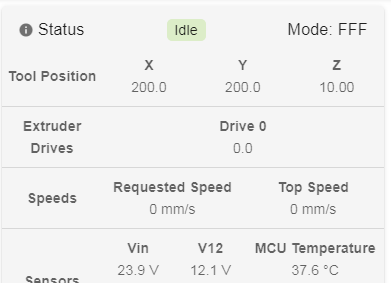

@deckingman Looks like this:

Can't extrude or retract.

Do I see the extruder drive?

Why yes! Yes I do.

"under extrusion control, do you see "E0" listed?"

Why no! No I don't.

See above picture. Just states Extrusion Control nothing about a particular extruder. I take it maybe it should?M302!! Okay. M302 P1 seems to make no difference. Dang.

However! M302 S120 R110 then heating the extruder up to 160C (but only in active mode not standby)

Lights up the Retract and Extrude and they now work.Thanks much deckingman, that's entirely what I was missing. No wonder I couldn't find anything about it.

-

@kcress Just to clear up a few points.

-

It seems that if you only have one extruder, then the web interface will not show E0. I have multiple extruders which is why I do see E0 (and also E1, E2 etc).

-

M302 P1 should have worked I don't know what it didn't work for you.

-

You wouldn't normally use M302. By default, extrusion is disabled if the hot end is not heated - this is to prevent accidental extrusion which would otherwise strip the filament or possibly cause other damage. If no M302 command is sent, then default temperature values will apply (but I can't remember off hand what those values are).

-

For normal operation, you simply make a tool active and set it's temperature to normal print temperature. Once the temperature rises above the values set by M302 (whether they be default values or ones that the user sets), then the extrusion control buttons will cease to be greyed out.

-

-

-

Check.

-

Tried M302 P1 four times. It may have allowed the extruder to run on the 6HC but I'm thinking the DWC may have still been blocking the sending of any extrude or retraction presses while it looked only at the temperature before enabling the sowtware buttons. e.g. if I'd have sent the extrude G code it probably would've extruded.

-

Totally get this but because this new extruder has never seen filament and I was in commissioning mode I never even thought about heat at all.

-

Thanks for clearing this up. Makes sense.

The default temp allowing extrusion is 160C while the default temp allowing retraction is 90C.

Thanks again. This bought me a night of sleep.

Count this one solved.

-

-

undefined T3P3Tony marked this topic as a question

undefined T3P3Tony marked this topic as a question

-

undefined T3P3Tony has marked this topic as solved

undefined T3P3Tony has marked this topic as solved

-

@kcress most likely you did not have a tool selected when extrusion was not working after sending M302 P1.

Some users with single-tool machines put a T0 command at the end of config.g so that the tool is already selected after startup.

-

@dc42 More learning. Thanks!