Input Shaper tuning - help required

-

Hi all,

I have recently (during the weekend) installed the Toolboard 1.1 on my RatRig V-Core 3. It has been configured and is (mostly) working as expected (there is a hotend/heatsink fan misconfiguration I am fighting with, but that's another story).

Input Shaper is what I am struggling with at the moment.Firstly, here's the current configuration:

Acceleration for X, Y and E axis is 10K mm/s^2, well within the capabilities of the printer. Accelerometer orientation is defined according to the wonderful document here.M955 P20.0 I10After that, I have run a test command for X axis, according to documentation:

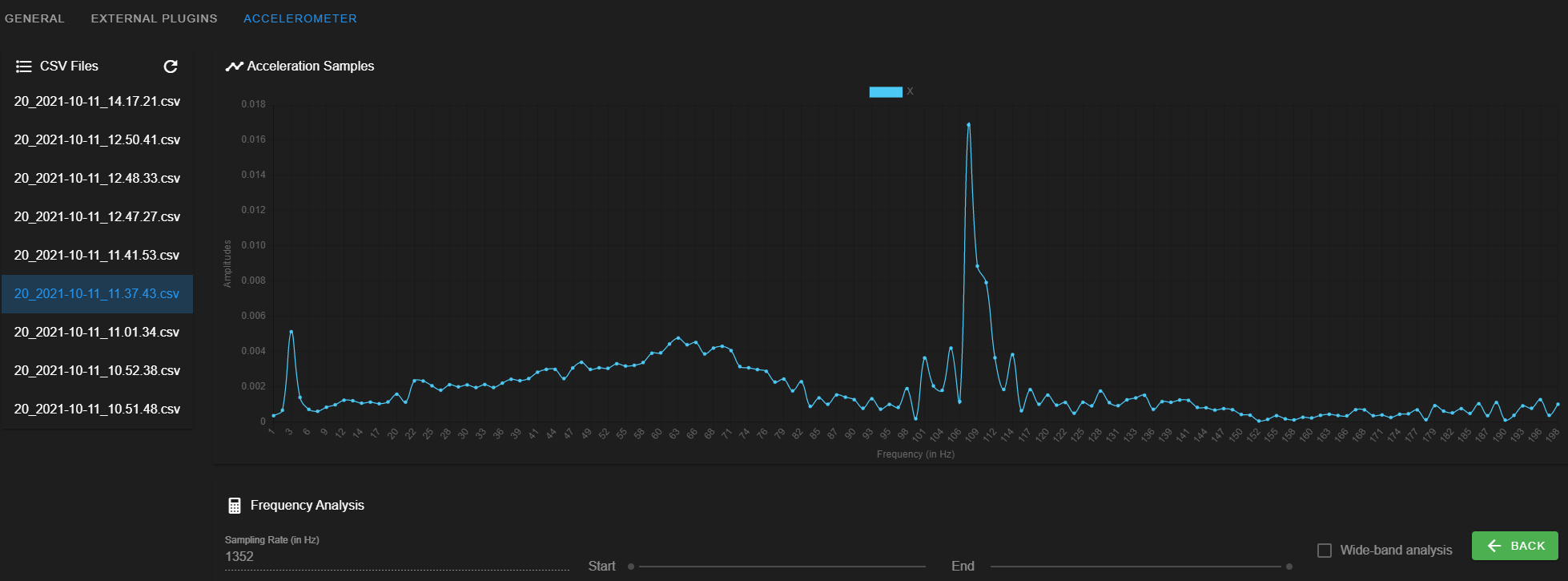

G1 X-50 G4 S2 G1 X50 F20000 M400 M956 P20.0 S1000 A0Analyzing the data using the Accelerometer embedded plugin yielded this result:

There are two spikes, one at 107.6 +/-0.7 Hz, and a smaller one at 3.4 +/- 0.7 Hz.I have then used M593 to use that frequency:

M593 P"zvd" F107.6Finally, printed a 50x50x50mm empty cube with two walls, using a 0.6mm nozzle at 100mm/s speed for all features, 0.2mm layer height. There is ringing present in all prints. It almost seems as Input Shaper is not being applied. Running M593 during print shows it is active, here's an example from the console while printing the cube with a slightly different frequency every 25 layers (10 changes):

M593 Input shaping 'zvd' at 107.7Hz damping factor 0.10, min. acceleration 10.0, impulses 0.334 0.822 with durations (ms) 4.67 4.67Looking at the printed part, there is no ringing/ghosting change throughout its height. I am, therefore, stuck at this step, not knowing how to further troubleshoot what's going on.

Any help would be much appreciated!

Thank you in advance for advice! -

@war4peace which axis of the print displays the ringing? If it is on the X axis, that doesn't necessarily mean that X axis ringing is to blame, it's more likely to be Y axis ringing. So run accelerometer tests on Y as well.

You can also estimate the ringing frequency by dividing the perimeter printing speed in mm/sec by the pitch of the ringing in mm.

100Hz is an unusually high ringing frequency for a 3D printer. Around 40Hz is more common.

-

@dc42

Thank you for your reply.

The 107 Hz value seems to come from faint motor vibrations or heat sink fan vibrations - it's present throughout the sample.

I switched to using a Klipper ringing tower which makes it clear which axis has ringing. The X axis has definitely more prominent ringing than Y axis.

I have now used the traditional method to divide ringing pitch to print speed and came with a value of 29.35, testing it now for various accelerations (1200 to 6800).Forgot to mention Jerk is at 600 mm/min for X, Y and E.

One question: what is „damping factor” and how does it affect Input Shaper algorithm? Also, I looked at M593 document, but it doesn't say much about damping factor.

-

Some updates on Input Shaper... I have followed the good old method outlined in the Klipper documentation, and found (through manual measurements) that ringing occurs at 29.4 Hz. Applied "zvd" algorithm and printed the ringing tower at accelerations between 1200 and 6800. Ringing is almost, but not fully gone up to around 4400-4600 acceleration, then it becomes more prominent again.

Maybe damping factor would help? Or should I try different algorithms, such as zvdd?

-

@war4peace ZVDD is less sensitive to getting the ringing frequency exactly right, so worth a try.

I am guessing that you have a Cartesian bed slinger printer. If so then the predominant ringing is likely to be the bed. If you are using a standalone accelerometer mounted on the print head, then try mounting it on the bed instead so that you can measure Y axis ringing.

-

@dc42

I have a CoreXY printer, the RatRig V-Core 3 500x500x500, as mentioned in my first post on the thread. Could be that the long belt paths are not helping at high(er) accelerations.

It has a kinematic bed, and while Y movements move the 20x20 extrusion together with the head assembly, and X movements only move the head assembly, both motors contribute to the movement, and most of the ringing is visible after an X movement ends and an Y movement begins.I'll try ZVDD using accelerations between 1200 and 6800 and update this thread.

-

After many tries and configuration changes, I am starting to suspect something is loose in my print head assembly.

I will disassemble, check and reassemble the print head tomorrow and update with my findings.