Hints for accelerometer placeing

-

Good morning, I've took the last step to improve (or to play with) my CoreXY printer so I've ordered an LIS3DSH Triple-Axis Accelerometer to implement the input shaping. I'd like to have some hints about where's the better placing for the PCB...I thought to re desing the Chimera support to place it right in front of the Chimera itself (orthogonal to the bed)...in your opinion would it be better to place it as near as possible to the nozzels or as "high" as possible?

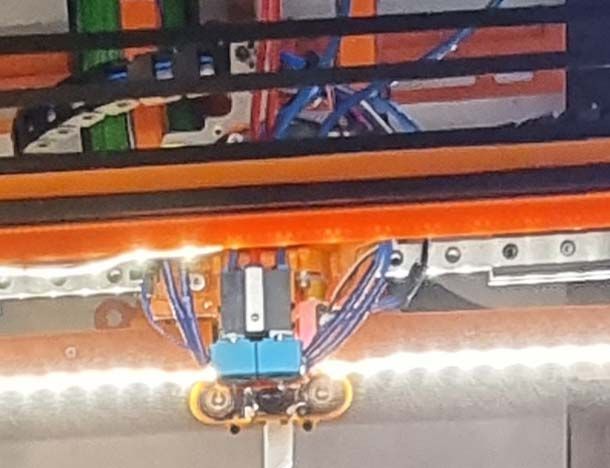

Here's my extruder (now I've mounted two Volcanos in place of the classic E3DV6):

Thanks!

-

@thedragonlord the accelerometer is best placed as close to the nozzles and as tightly mechanically coupled to them as possible without creating additional issues (e,g, cooling) it is possible to have the pcb mounted only when collecting the data, and that does not need the nozzles to be hot to do that.

-

@t3p3tony said in Hints for accelerometer placeing:

@thedragonlord the accelerometer is best placed as close to the nozzles and as tightly mechanically coupled to them as possible without creating additional issues (e,g, cooling) it is possible to have the pcb mounted only when collecting the data, and that does not need the nozzles to be hot to do that.

Uh, ok...but I don't understand a thing...I thought that the accelerometer was used by the board even when printing..am I wrong? Is it used "only" for collecting data wich will be used after during the print (like the bed leveling mash data for example)?

-

@thedragonlord the accelerometer is used for collecting data that allows you to select an appropriate input shaping frequency and shaping type to reduce ringing. after that has been determined the accelerometer does not need to remain fitted to the printer.

-

@t3p3tony said in Hints for accelerometer placeing:

@thedragonlord the accelerometer is used for collecting data that allows you to select an appropriate input shaping frequency and shaping type to reduce ringing. after that has been determined the accelerometer does not need to remain fitted to the printer.

ok, that's the proof that I need to study a lot before the accelerometer arrives from England where I've ordered it!

Thanks!

-

@t3p3tony said in Hints for accelerometer placeing:

@thedragonlord the accelerometer is used for collecting data that allows you to select an appropriate input shaping frequency and shaping type to reduce ringing. after that has been determined the accelerometer does not need to remain fitted to the printer.

Ok, I've read again the documentation at https://duet3d.dozuki.com/Wiki/Accelerometers as well a the GCODE dictionary for M593 and I've realized that I haven't understood a...thing...The accelerometer is used to gather data wich can be viewed in the graph using the DWC plugin. The M593 has to be configured to "neutralize" a single frequency, right? So the question is how can i "translate" the data gathered by the accelerometer to a single frequency for the M593 I mean how can I get the "guilty" frequency from the graph? In the graph there are the samples on X and acceleration on Y how is the frequency "calculated" from this data?

I apologize if this question is stupid but I'm trying to learn and sometimes it's a little hard without help...unfortunately (for my wallet) curiosity and will to experiment new thing are my Acchilles heel...

Thanks

-

@thedragonlord the input shaping plugin will show the detected frequencies see this thread for the latest development of the plugin:

https://forum.duet3d.com/topic/24859/inputshaping-plugin-0-1-0-rc7-released-repacked/15 -

@t3p3tony said in Hints for accelerometer placeing:

@thedragonlord the input shaping plugin will show the detected frequencies see this thread for the latest development of the plugin:

https://forum.duet3d.com/topic/24859/inputshaping-plugin-0-1-0-rc7-released-repacked/15excellent, thanks

-

@t3p3tony said in Hints for accelerometer placeing:

@thedragonlord the input shaping plugin will show the detected frequencies see this thread for the latest development of the plugin:

https://forum.duet3d.com/topic/24859/inputshaping-plugin-0-1-0-rc7-released-repacked/15this is the accelerometer I've bought: https://www.ebay.it/itm/273191600064 (of course I'll upgrade the FW to 3.4 beta 2) in your opinion a normal non shielded flat ethernet cable like this https://www.amazon.it/gp/product/B00UPHN938/ref=ppx_yo_dt_b_search_asin_title?ie=UTF8&psc=1 (wich I already own) could be fine? (Of course following the hint to keep the CS cable as far as possible from other signal cables). In case not what cable would be best?

Thanks

-

@thedragonlord No idea if the flat ethernet cable will work or not, you probably just have to try it. If it doesn't then several folks (including myself) have been successful using USB3 cable and wiring in the way described here: https://forum.duet3d.com/topic/22878/software-package-3-3beta3-released/68?_=1624809172098

-

@gloomyandy said in Hints for accelerometer placeing:

@thedragonlord No idea if the flat ethernet cable will work or not, you probably just have to try it. If it doesn't then several folks (including myself) have been successful using USB3 cable and wiring in the way described here: https://forum.duet3d.com/topic/22878/software-package-3-3beta3-released/68?_=1624809172098

excellent, thanks

-

I have a Delta printer using a Duet smart effector, I'm using a Duet3d 6hc3 sys board.

Where would you mount an accelerometer to the smart effector?

Wiring is not the issue, it is the physical location.

-

@amjm22 I mounted mine on top of the effector, using a single screw to attach it to one of the 3 mounting holes in the effector, with a couple of nuts as spacers.

-

@dc42 Any rigid location on top of the effector could suffice?

I am thinking of using double side tape, or printing a small base to be glued on top -

@dc42 Much appreciated! I will give it a shot when the accelerometer arrives! i post the results.

-

@ignacmc said in Hints for accelerometer placeing:

@dc42 Any rigid location on top of the effector could suffice?

Yes. Here is a photo of the way I mounted mine.

-

@dc42 That photo made me smile. I came here looking for advice on accelerometer placement, and invisioned all sorts of fancy printed mounts. Then I find this. Quick. Cheap. Efficient. Moving on.

Thank you.

-

@janjoh I would guess the corner mount like will have it's own artifacts. It may or may not matter, but looks like a spring board and will certainly have a dominant frequency related to the mounting alone. Simply test on a nice solid block of Al or something by mounting in the same fashion and give it a few taps in x, y, z directions and see what you get.

-

@tommyb if the screws are tight then I am sure that the resonant frequencies of the mounting mechanism will be much higher than those of the arms + effector mass that I am interested in.