Odd mechanical failure

-

@deckingman Interesting. When the machine is running normally, do the pulleys find a spot and stay there or do they wander up and down the shaft a bit as the belt reverses direction?

-

@mrehorstdmd said in Odd mechanical failure:

@deckingman Interesting. When the machine is running normally, do the pulleys find a spot and stay there or do they wander up and down the shaft a bit as the belt reverses direction?

No they stay put once the belts have been tensioned and few longish moves have been completed. If you think about it, the force direction is completely in line with the belt - so it's completely horizontal - there is no upward or downward vector which would be needed to make the idler travel up and down the shaft. Or to put it another way, the belts are always under tension so you can think of them like stiff rods. The only way that one end of that rod can rise up or down is if the rod becomes the hypotenuse of a right angle triangle with the belt being the adjacent side and the shaft being the opposite side. But that hypotenuse would be longer than the adjacent side so it would need to somehow grow in length. Which ain't going to happen unless it stretches. For a belt to do that would mean that it would have to stretch to the point where it becomes slack and that ain't going to happen either (well it might if one used elastic bands instead of timing belts

).

).I don't know if you've ever seen any old industrial sites where a number of machines ran off leather belts running on a common shaft driven by a single water wheel or steam engine. If you have you'll have seen that there are no flanges on the pulleys. The belts stay put on the pulleys just by virtue of the fact that they run at right angles to the shaft. It's the same principle.

As an aside, here in the UK the time when the work day finishes is often referred to as "knocking off time". Not many people know the origin of that expression but in days gone by when machines were powered as I described with belts and pulleys the method of stopping the machine was to use a large lump of wood to knock the belt off the pulley. Hence " knocking off time" became synonymous with the end of the working day.

Note that if pulleys had been fitted with flanges, they wouldn't have had a quick means of stopping the machine and the world would be a poorer place without "knocking off time"

-

My wife often tells me to knock it off. Now I know what she means.

-

@deckingman said in Odd mechanical failure:

"knocking off time"

You learn something every day!

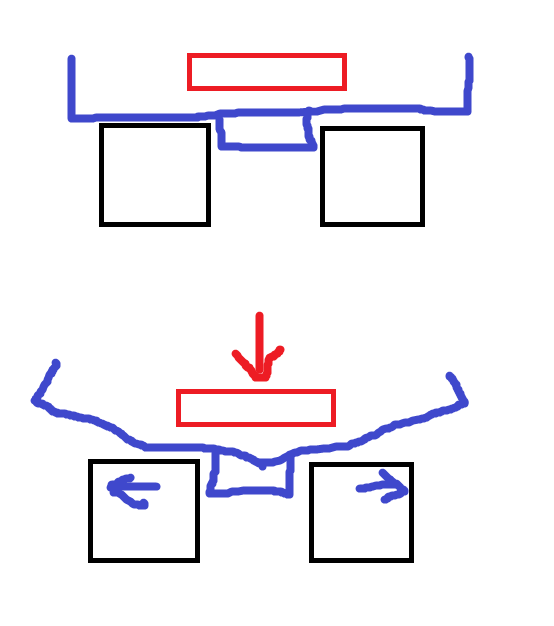

Very interesting post and you've got me thinking! My theory would be that the excessive load caused the idler to deflect into more of a v-shape which would then gibe you equal and opposite axial loads on either bearing and push them out (in the dodgy sketch below, red is belt, blue is idler, black are bearings with the axis going horizontally). You may also get something similar if the axle/bolt were to deflect a bit (though given that's steel maybe not...). In normal running, the idler shouldn't deflect that much so would probably be negligible, and the radial load on the bearing should provide some friction to prevent the outer raceways walking out, even if the press fit it only weak.

-

I am having a rough day so I am arguing with everybody .... Pulleys with no flanges are not flat. They are crowned in the middle.

-

@jens55 Yeah, I would have thought the old belt driven factory machines had crowned pulleys to keep the belts in place. But with leather belts, maybe crowning would not have worked well and letting them self-align would be better.

@deckingman I'd like to test this idea in my printer but I used stacked flanged bearings for the pulleys and there's nothing keeping them together except the stacks of nylon washers that prevent them moving along the shafts.

Maybe my next printer...

-

@mrehorstdmd If you do try it, there is one place where I do use a spacer and that is on the underside of the upper idlers. It still allows some degree of freedom of movement, but it makes the initial fitment of the belts a lot easier, because until the belts are tensioned, the pulleys will drop to the bottom of the shafts. So having a spacer on the underside helps by holding the pulley roughly where it needs to be while fitting the belts.

Ref your situation, I've found those Open Builds idlers to be good. They have double bearings, and they are made of Delrin, and they are bigger in diameter than others that I've seen. They are probably lighter than your flanged bearings if that's of any interest. You'll note that I don't twist belts and haven't had any issues with the toothed side running on the idler.

HTH

-

@engikeneer It may have been something like that although there is minimal gap between the bearings and that is taken up with a nylon spacer.

I guess we would only know what really happened if I repeated the fault condition and filmed it with a high speed camera. But I'm still finding damage to repair from when it happened so I'm not about to try it again.

-

@jens55 said in Odd mechanical failure:

I am having a rough day so I am arguing with everybody .... Pulleys with no flanges are not flat. They are crowned in the middle.

Did you also know that the rims of the wheels on locomotives and rolling stock are not square to the rails, but at an angle? The reason is that each pair of wheels is fixed to the same axel so they always rotate at the same speed. But when the rails make a bend, the outer rail is longer than the inner rail. so the outer wheels have to travel further than the inner wheels. When the loco or carriage gets to the bend, it wants to carry in straight so it tends towards the outside of the bend. This pushes the wheel rims to one side, and because of the angled face of the rim, the outer ones have an effective increase in diameter, and the inner ones decrease. Thus allowing the outer wheels to travel further than the inner wheels.

-

@deckingman, you got me there, I did not know that ....