After updating to 3.4.0beta2: faulty heater 1, -273.1C.

-

@dc42 Ok, thanks. How to do that ? I have a SBC.

-

-

@dc42 when i do an emergency stop, the system does not restart. I have to do a sudo reboot of the SBC and it takes a very long time to restart. When I then update the firmware of the toolboard, the temperature indicated is 2000 °. I have to turn off the Duet and restart it. The indicated temperature is then 10 ° lower and very unstable.

-

@serge when the temperature reading is incorrect, what happens if you send:

M98 P"config.g"

Please post your config.g file.

-

-

@juliann said in After updating to 3.4.0beta2: faulty heater 1, -273.1C.:

What I am missing by using v3.3 on the toolboard, can I still testing input shaping or this feature is only available in 3.4?

You can still test input shaping. Very little has changed in the expansion/tool board firmware.

-

@dc42 Enregistrement d'écran 2021-08-03 à 17.18.41.mp4

M98 P"config.g"

Error: Operation failed (Reason: NullReferenceException in SimpleCode: Object reference not set to an instance of an object.); Configuration file for Duet 3 (firmware version 3)

; executed by the firmware on start-up

;

; generated by RepRapFirmware Configuration Tool v3.2.3 on Fri Jun 18 2021 23:17:45 GMT+0200 (heure d’été d’Europe centrale)G4 S1 ;wait for expansion boards to start

; General preferences

G90 ; send absolute coordinates...

M83 ; ...but relative extruder moves

M550 P"Duet 3" ; set printer name

M669 K1 ; select CoreXY mode

G29 S1 ; Set Units to Millimeters; Drives

M569 P0.0 S0 D3 ; physical drive 0.0 goes forwards

M569 P0.1 S0 D3 ; physical drive 0.1 goes forwards

M569 P0.2 S0 D3 ; physical drive 0.2 goes forwards

M569 P0.3 S1 D3 ; physical drive 0.3 goes forwards

M569 P0.4 S1 D3 ; physical drive 0.4 goes forwards

M569 P20.0 S1 ; physical drive 20.0 goes forwards

M584 X0.4 Y0.3 Z0.0:0.1:0.2 E20.0 ; set drive mapping

M350 X16 Y16 Z16 E16 I1 ; configure microstepping with interpolation

M92 X80.00 Y80.00 Z800.00 E836.00 ; set steps per mm

M566 X2520.00 Y2520.00 Z480.00 E2520.00 ; set maximum instantaneous speed changes (mm/min)old 2520 for XY

M203 X30000.00 Y30000.00 Z900.00 E3600.00 ; set maximum speeds (mm/min)

M201 X3000.00 Y3000.00 Z320.00 E3600.00 ; set accelerations (mm/s^2)Old 3480 for XY

M906 X1600 Y1600 Z1200 E900 I30 ; set motor currents (mA) and motor idle factor in per cent

M84 S30 ; Set idle timeout

M671 X0:200:409 Y-2:407:-2 S5 ; define positions of Z leadscrews or bed levelling screws; Axis Limits

M208 X0 Y0 Z0 S1 ; set axis minima

M208 X410 Y400 Z400 S0 ; set axis maxima; Endstops

M574 X1 S1 P"20.io1.in" ; configure active high endstops

M574 Y2 S1 P"io1.in" ; configure active high endstops

M574 Z1 S2 ; configure Z-probe endstop for low end on Z; Z-Probe

M558 P8 C"20.io0.in" I1 H3 F600 69000 ; set Z probe type to unmodulated and the dive height + speeds

G31 P1000 X-27.8 Y-12 Z1.668

M556 S280 X-1.25 Y0 Z0 ; set orthogonal axis compensation parameters; set Z probe trigger value, offset and trigger height

M557 X15:380 Y15:380 S35 ; define mesh grid; Heaters

M308 S0 P"temp0" Y"thermistor" T100000 B3950 A"Bed" ; configure sensor 0 as thermistor on pin temp0

M950 H0 C"out1" T0 ; create bed heater output on out1 and map it to sensor 0

M307 H0 B0 R0.706 C344.2 D4.98 S1.00 ; disable bang-bang mode for the bed heater and set PWM limit

M140 H0 ; map heated bed to heater 0

M143 H0 S120 ; set temperature limit for heater 0 to 120C

M308 S1 P"20.temp0" Y"thermistor" T100000 B4725 C7.06e-8 A"Hotend" ; configure sensor 1 as thermistor on pin 20.temp0

M950 H1 C"20.out0" T1 ; create nozzle heater output on 20.out0 and map it to sensor 1

M307 H1 B0 R5.925 C228.4:147.2 D9.34 S0.50 V24.0 ; disable bang-bang mode for heater and set PWM limit

M143 H1 S285 ; set temperature limit for heater 1 to 285C; Fans

M950 F1 C"20.out2" Q500 ; create fan 0 on pin 20.out2 and set its frequency

M106 P1 C"Hotend Fan" S1 H1 T45 ; set fan 0 value. Thermostatic control is turned on

M950 F0 C"20.out1" Q500 ; create fan 1 on pin 20.out1 and set its frequency

M106 P0 C"Layer Fan" S0 H-1 ; set fan 1 value. Thermostatic control is turned off; Tools

M563 P0 D0 H1 F0 ; define tool 0

G10 P0 X0 Y0 Z0 ; set tool 0 axis offsets

G10 P0 R0 S0 ; set initial tool 0 active and standby temperatures to 0C

M955 P20.0 I24 S60 R10 ; Configure Accelerometer

M956 P20.0 S60 A0 ; Collect accelerometer data and write to file; EVA 2 / BMG / E3D V6

M92 E830 ; set extruder steps per mm, 1.8 angle/step

M906 E800 ; set extruder motor current (mA) and idle factor in per cent

M404 N1.75 D0.4 ; Filament and nozzle diameter

T0; Custom settings

; Pressure Advance

M593 F43.48

M221 D0 S100

M207 S0.4 F3000 Z0.00

M200 D1.75

M572 D0 S0.083

M912 P0 S14; Miscellaneous

M501 ; load saved parameters from non-volatile memory

M911 S10 R11 P"M913 X0 Y0 G91 M83 G1 Z3 E-5 F1000" ; set voltage thresholds and actions to run on power loss -

@serge thanks, that error is one for @chrishamm.

-

@dc42

Thanks, i have to send him the bug ? -

@serge said in After updating to 3.4.0beta2: faulty heater 1, -273.1C.:

@dc42

Thanks, i have to send him the bug ?No, I have asked him to look at your post.

-

@juliann, to help me diagnose this, please can you reload the new tool board firmware, then send M308 S1 with no further parameters, and report the response.

-

@dc42 said in After updating to 3.4.0beta2: faulty heater 1, -273.1C.:

M308 S1

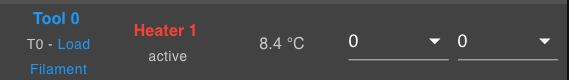

After reloaded the new 3.4b2 firmware on the toolboard the behaviour changed. The reading is not good but now the heater is active instead of faulty (and temp should be around 25C).

M308 S1:

M308 S1 Sensor 1 type Thermistor using pin 20.temp0, reading 7.4, last error: sensor not ready, T:500000.0 B:4723.0 C:1.20e-7 R:2200.0 L:-5 H:-9``` -

@juliann thanks. I am looking into it.

-

@juliann Yes, exactly the same issue i have.

-

@dc42 Same for me.

And after a very long time idle, the sensor temp works around the bed sensor temp but is very unstable :

-

@serge said in After updating to 3.4.0beta2: faulty heater 1, -273.1C.:

@juliann Yes, exactly the same issue i have.

Yes @Serge I think you are correct, it seems we have exactly the same issue now.

-

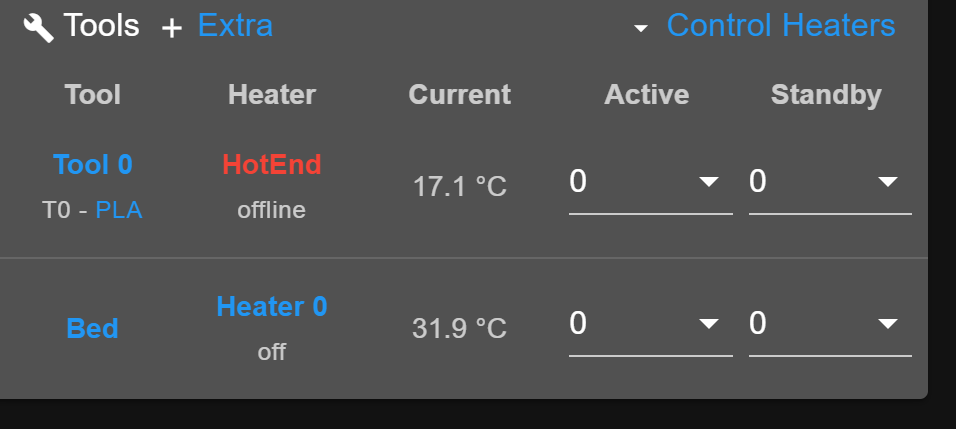

Rolling back the toolboard firmware to 3.3, and no issue than 6° higher for the hotend than the bed sensor. But stable.

-

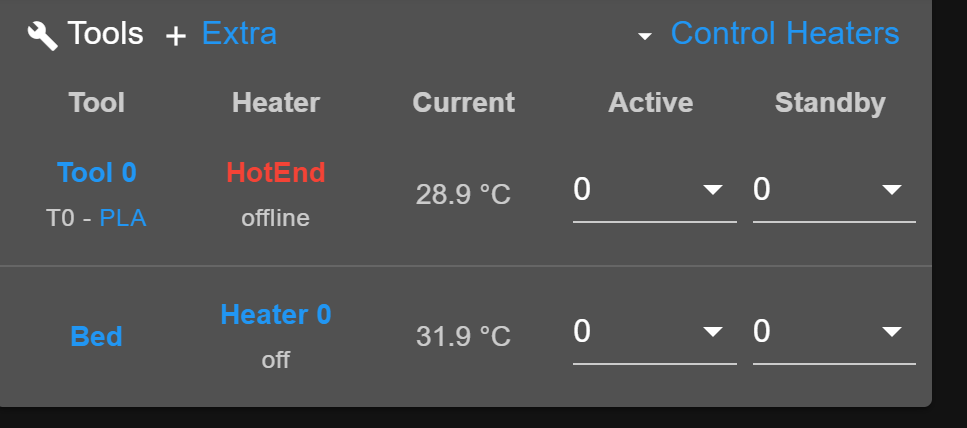

I can confirm also a kind of this bug.

Before the update I had around 29°C on the HotEnd.M308 S1 P"121.temp0" Y"thermistor" A"HotEnd" T100000 B4725 C7.06e-8

-

-

@empi00 I am wondering whether it just needs different calibration. Please can you:

- Send M308 S1 (assuming the tool board thermistor is Sensor 1) and record the result, in particular the H and L values.

- Send M122 B121 and record the reported VIN value

- Switch the tool board firmware to 3.4beta2.

- Send M308 S1 again, check that it reports the same H and L

- Send M122 and check tna the reported VIN value is the same as before

- Run the calibration procedure described at https://duet3d.dozuki.com/Wiki/Calibrating_thermistor_and_PT1000_readings on the tool board thermistor input. If it's tricky to do the short-circuit calibration test, just do the open-circuit calibration, which should be sufficient to correct the reading at room temperature.

- Send M308 S1 again to see the new H and L values

- Check whether the readings are now correct.

I am assuming that you do not have H and L parameters in your M308 commands in config.g, so it will use the values stored in NVRAM.