Nema 34 Z axis shakes and does not move

-

Hello there,

I built a large corexy printer. I used Nema 34 for x, y and z axes. I used LeadShine M880 drivers. Movement in the x and y axes is excellent. But there is constant shaking in the Z axis and I can move it up by hand. I used 4 ballscrews and 4 nema 34 in the Z axis. How do you think I can solve this problem?config.g

; Configuration file for Duet WiFi (firmware version 2.03) ; executed by the firmware on start-up ; ; generated by RepRapFirmware Configuration Tool v3.2.3 on Tue Apr 06 2021 20:07:03 GMT+0300 (Doğu Avrupa Yaz Saati) ; General preferences G90 ; send absolute coordinates... M83 ; ...but relative extruder moves M550 P"SAN-ART" ; set printer name M669 K1 ; select CoreXY mode ; Network M552 S1 ; enable network M586 P0 S1 ; enable HTTP M586 P1 S0 ; disable FTP M586 P2 S0 ; disable Telnet ; Drives M569 P5 R1 T2.5:2.5:5:5 S1 ; physical drive 5 goes forwards (X) M569 P6 R1 T2.5:2.5:5:5 S1 ; physical drive 6 goes forwards (Y) M569 P7 R1 T2.5:2.5:2.5:2.5 S1 ; physical drive 8 goes forwards (Z) M569 P3 S0 ; physical drive 3 goes forwards M584 X5 Y6 Z7 E3 ; set drive mapping ;M569 P0 S1 ; physical drive 0 goes forwards ;M569 P1 S1 ; physical drive 1 goes forwards ;M569 P2 S1 ; physical drive 2 goes forwards ;M584 X0 Y1 Z2 E3 ; set drive mapping M350 X256 Y256 Z16 E16 I1 ; configure microstepping with interpolation M92 X14.00 Y14.00 Z357.00 E420.00 ; set steps per mm M566 X8000.00 Y8000.00 Z60.00 E1000.00 ; set maximum instantaneous speed changes (mm/min) M203 X8000.00 Y8000.00 Z500.00 E1000.00 ; set maximum speeds (mm/min) M201 X2000.00 Y2000.00 Z500.00 E1000.00 ; set accelerations (mm/s^2) M906 X1800 Y1800 Z800 E800 I30 ; set motor currents (mA) and motor idle factor in per cent M84 S30 ; Set idle timeout ; Axis Limits M208 X0 Y0 Z0 S1 ; set axis minima M208 X900 Y900 Z1000 S0 ; set axis maxima ; Endstops M574 X1 Y1 Z1 S1 ; set active high endstops ; Z-Probe M558 P0 H5 F120 T6000 ; disable Z probe but set dive height, probe speed and travel speed M557 X15:215 Y15:195 S20 ; define mesh grid ; Heaters M307 H0 B0 S1.00 ; disable bang-bang mode for the bed heater and set PWM limit M305 P0 T100000 B4138 R4700 ; set thermistor + ADC parameters for heater 0 M143 H0 S120 ; set temperature limit for heater 0 to 120C M305 P1 T100000 B4138 R4700 ; set thermistor + ADC parameters for heater 1 M143 H1 S280 ; set temperature limit for heater 1 to 280C ; Fans M106 P0 S0 I0 F500 H-1 ; set fan 0 value, PWM signal inversion and frequency. Thermostatic control is turned off M106 P1 S1 I0 F500 H1 T45 ; set fan 1 value, PWM signal inversion and frequency. Thermostatic control is turned on ; Tools M563 P0 D0 H1 F0 ; define tool 0 G10 P0 X0 Y0 Z0 ; set tool 0 axis offsets G10 P0 R0 S0 ; set initial tool 0 active and standby temperatures to 0C ; Custom settings are not defined -

When steppers vibrate but don't move they are usually either wired incorrectly or the motor current is set much too high or too low. If you're using external drivers you have the additional complication of setting the timing for the step/dir/enable lines as well as wiring them correctly.

How big is this machine that it needs 4 x NEMA-34 motors to lift Z?

-

@mrehorstdmd

It worked very nicely on Mach3 cnc software. I don't think there is a problem with drivers either. Printer printing area is 1.5mx1m.

From which value will I start the current values?

-

@rutku That's quite a machine!

You typically run the motors at 70-80% of rated current.

Was the mach3 software running on the Duet board? If not the pinout and voltage levels on the controller board for the step/dir/enable signals may be different. Was the timing for those signals the same?

Looking at the M569 statements, you've got much "sharper" timing set for the slow Z axis than for the much faster moving X and Y axes. I'd probably stretch out the Z axis timing a bit.

If you can't seem to find your wrench, it's sitting on the motor mount in the front of the picture!

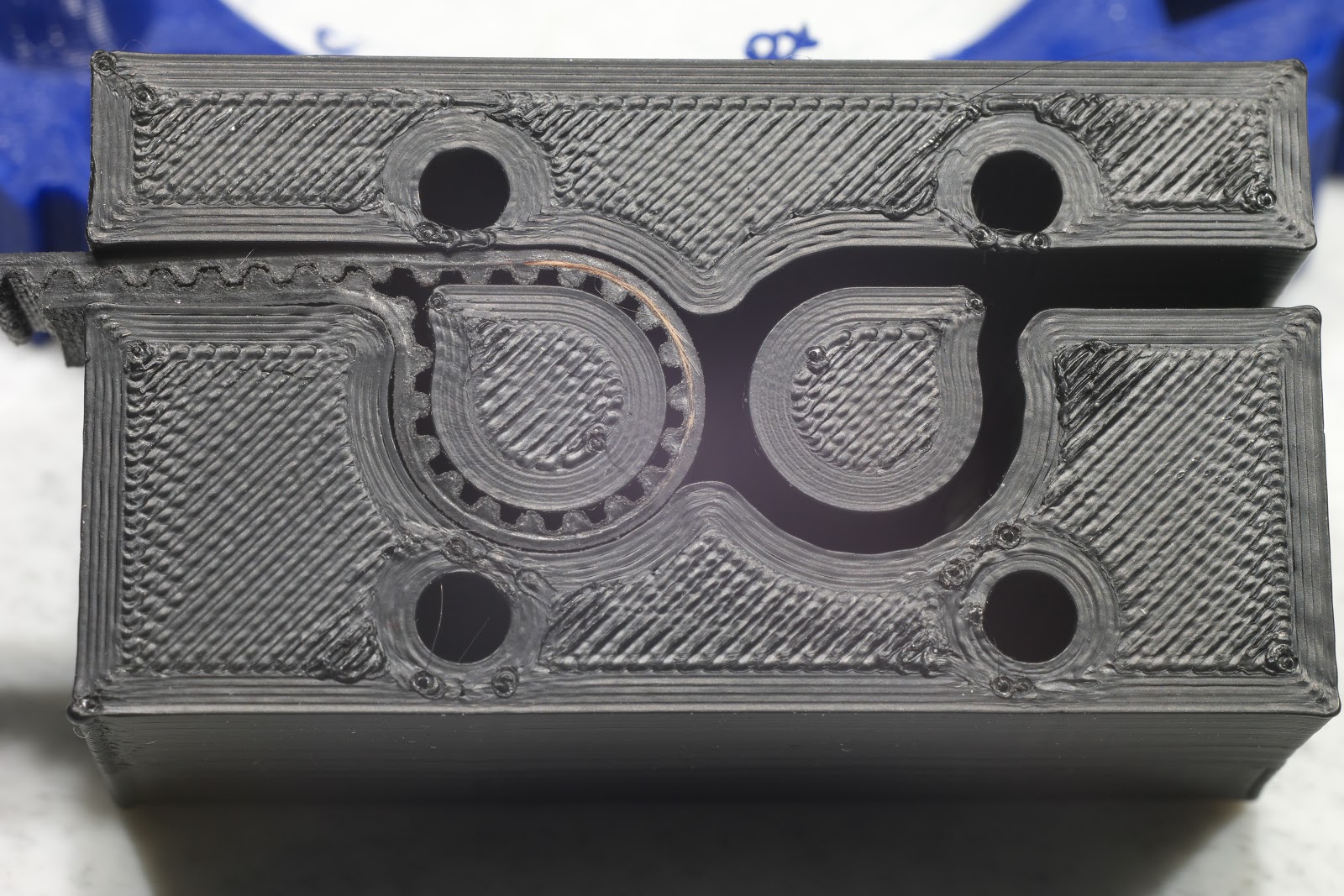

Are those steel core belts in the X and Y axes? If so you might consider switching to glass core. Steel core belts don't usually last long when they are forced to bend over small pulleys. The wires in the core will snap from the fatigue and then the polyurethane belt will stretch over the wires and cause all sorts of mysterious problems. The clamps holding the belts at the extruder carriage are also a potential problem. Here's the result of using a similar clamp on the steel Z axis belts in my printer:

It's best to fold the belts back on themselves so the teeth interlock like this:

-

@rutku, as @mrehorstdmd says there is no reason to use faster M569 timing for the Z axis, if you are using the same type of driver for all 3 axes. So change the M569 P7 command to use the same timing as the other two.

-

@mrehorstdmd @dc42 Thank you for your help. I solved the problem by increasing the current through the driver. I will replace the belt based on your advice. I'm putting the wrench there for luck.