Vertical banding on COREXY machine

-

@donstauffer I wonder, if acceleration is done in "quanta", rather than smoothly (it almost has to - digital computers), could this be the incrementing of speed from acceleration being "out of phase" between extruder and XY? Imagine, extrusion increases, then speed, then extrusion, then speed, etc. You'd get a pulsing effect, in terms of extrusion per mm travel. Except then it would only happen when speed is changing, I guess. Well, just a thought.

-

@mrehorstdmd no, that's not the reason, if I were overextruding the perimeter will be higher than 0.4mm I set but consistent and that's not the point and also y speed is double or later height double should show another different issues.

-

@donstauffer I don't know, that's out of my knoledge. What I can say is I inspected the gcode file and the gcode for the cube sides is go from A to B extruding C ammount of plastic at F speed so the extruder has one only order to follow and the cilinder has small tiny segments to be printed in the same way, if I can this afternoon will try to print a cube of 20mm and another of 80mm to see if it vary something but I think it will not.

Maybe @dc42 can shed some light to this issue

-

@zabana This is problematic, because I can't do much about regular ringing without low acceleration, but I can't eliminate this banding without at least 1200 acceleration, I assume because lower accelerations slow down printing. My ringing is at around 60Hz, and DAA at that frequency reduces it, but it must lower acceleration too much because the banding returns. My jerk is already around 300, and any lower seems to mess up corners without improving ringing.

So right now, the best I can do seems to be to have moderate ringing (reasonably high acceleration), or mild ringing and moderate to severe banding (rather low acceleration). And I don't have the option I do on my other printer to slow printing down to get nice prints.

PA between 0.15 and 0.20 seems to have helped basic print quality at high speed, so that at least enables me to print fast so I have minimal banding. I just have to tolerate moderate ringing.

I have no ideas what else to try, except to consider Klipper.

-

@zabana I do think you misunderstood my conjecture, although it may be wrong anyway. I wasn't suggesting it was overextrusion. I was suggesting that rather than a simple pulsing of the extruder, it might be the extruder and XY movements leapfrogging each other. That would cause alternating over- and under-extrusion, but little or no average difference in extrusion.

-

@donstauffer I'm seeing this identical issue on my Railcore II also. Test cubes and such show "waviness" identical to the images @DonStauffer posted. LDO 0.9 steppers and duet2 wifi (my Railcore is a filastruder kit version of recent vintage). Oddly it only seems to happen on X and not on Y. I've hooked up an accelerometer and captured some data with the 3.3 beta and note the difference between an identical simple move in the X and Y direction:

X

Y

These were something like a 100mm move at 80mm/s. I see basically the same thing at 40mm/s also as I recall.

After trying many different mechanical tweaks, and looking at some other prusa forum posts Don had mentioned, I was thinking it's possible it is stepper based and will be trying some moons steppers to see if that smooths and improves anything. It certainly could be how the steppers are being driven by the duet2 as well, though, of course, something I hadn't considered.

A bit of a mystery is why X seems more affected.. both steppers are moving, just in different directions, for a pure X and pure Y move, right? That's why I was inclined originally to think it was a mechanical vibration issue with my X carriage or X rails or something, but all sorts of tweaks and changes to that didn't yield any real notable changes to the accelerometer data.. even being able to make it worse would be an indication that it was mechanical, but I haven't been able to really change things much with mechanical tweaks. I could be just not doing the right thing, of course... I'm a computer engineer so real-world physical hardware is not my forte

Fixing or at least improving this would make a big impact on my print quality, so quite interested in any possible solutions. I will do some experiments with higher speeds as well, that is interesting.

-

@skrotz In corexy, moving Y moves only 4 of the pulleys on the belts. Moving X moves all the pulleys. It is a larger mechanical load on the motors to move the extruder in X than it is to move in Y- try pushing it manually with the motors off and you'll see.

-

Well, this afternoon did a few more test, you know just for the pleasure of havi g the same result always hehehe

I printed at 30mm/s all test and the changes was:

- updated fw to the latest one

- printed 20 , 40 and 80mm cubes

- changed nozzle to a phaetus one

- tried slicing with slic3r instead of simplify

- printed in vase mode

- printed at 210 instead 200 degrees

So I don't know what rlse to try but I am more than convinced that it is related on how on the duet wifi are managed slow moving as it happens on the extruder at such speed.

I also extruded on the air with the printed stopped 50mm of filament at 6 and 1 mm/s and the extruded filament has the pattern I see on the printed objects so it is like the stepper movement at low speeds is not smooth at all or something weird happens with back pressure or something like that...

-

@zabana said in Vertical banding on COREXY machine:

I also extruded on the air with the printed stopped 50mm of filament at 6 and 1 mm/s and the extruded filament has the pattern I see on the printed objects so it is like the stepper movement at low speeds is not smooth at all or something weird happens with back pressure or something like that...

Can you clarify exactly what it was you did for this test and perhaps post some pictures of the result? What happens if you extrude at the rate that is used with your "good" prints, does the extruded output then look smooth?

-

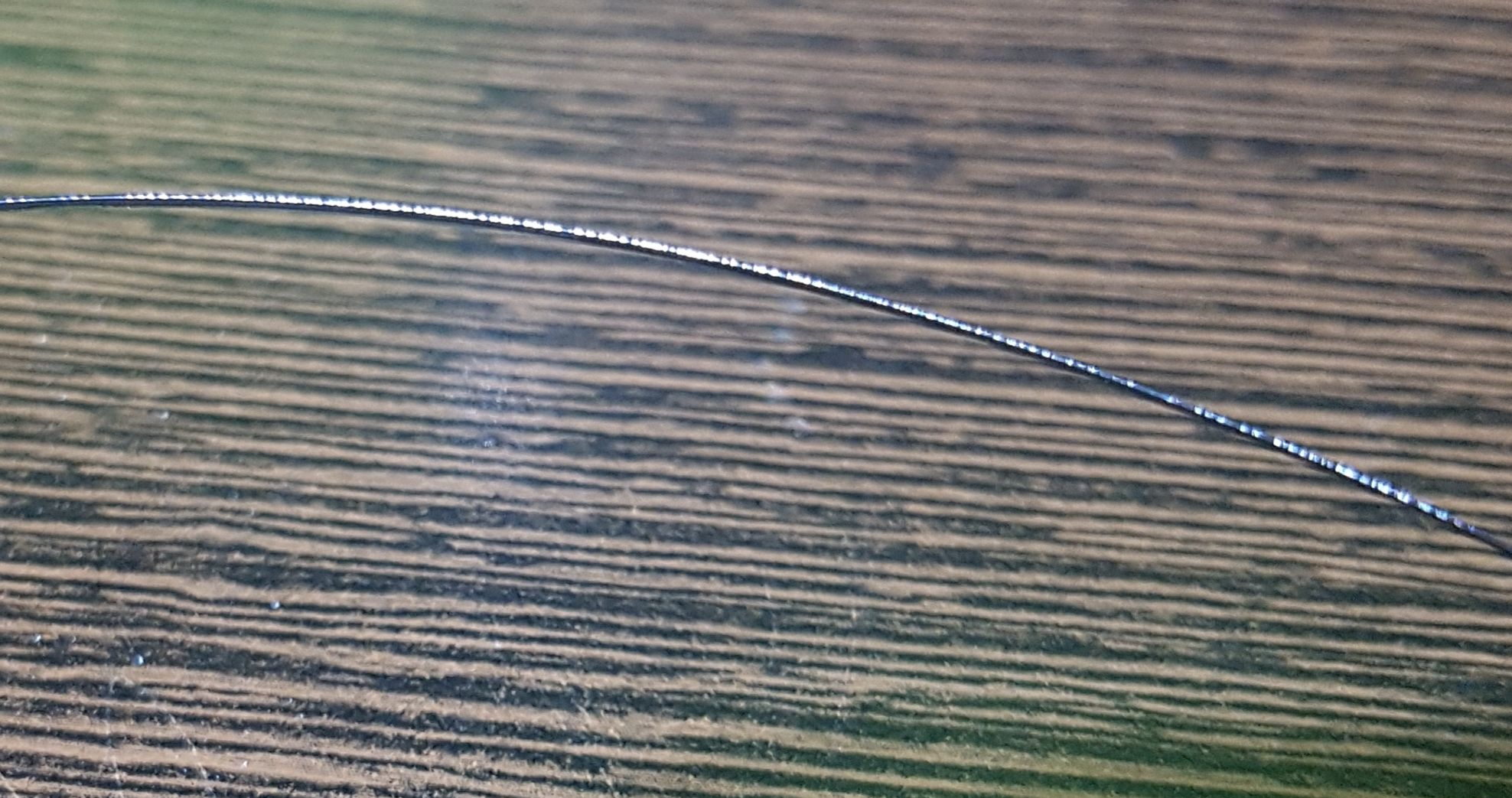

@gloomyandy it is difficult to take a pic of it but here it is. And the test is simple, just did an air extrusion lije when you want to prepare the hotend or simillar, just send thw G1 F6 E50 command on the console and that is all.

-

@skrotz I'm really happy to see the difference in 3.3beta. What RRF version is the top trace? The amplitude seems to be about half and the frequency quadrupled or so. Between the two I'd expect the artifact to be fairly obscure as a result.

What jerk & acceleration were these traces at? And typically how long before the released version of 3.3? I think I saw the RC announced recently.

-

@zabana I'm slightly confused. If the defect is caused by XY moves, why would it show in a midair extrusion, when theoretically only the extruder would be in play? Some kind of interplay between extrusion and XY moves?

-

@donstauffer here are the relevant settings:

M906 X1400 Y1400 Z1000 E800 I60 ; Set motor currents (mA)

M201 X3000 Y3000 Z100 E1500 ; Accelerations (mm/s^2)

M203 X24000 Y24000 Z900 E3600 ; Maximum speeds (mm/min)

M566 X1000 Y1000 Z100 E1500 ; Maximum jerk speeds mm/minuteI played with much lower jerk values but didn't see much change in the accelerometer data. Much lower accelerations seemed like it might have helped but on a test print of a calibration cube I still saw the exact same waviness as at higher acc.

Not sure what you mean by the difference in 3.3beta? I think you misunderstand, both of those images are from 3.3RC3, top one is an X movement and bottom is a Y movement.. I posted both to note the difference I see in X versus Y, and on my machine I don't see the waviness on Y really, just X, and looking at those two samples it kind of makes sense.

-

@donstauffer Maybe I did not explain properly but after all tests I did my only conclusion is that the artifacts are not related to XY moves but extruder moves. Of course there is a little bit ringing but also in the ringing due acceleration and deceleration I can see the periodic patron that gives the extruder. I don´t know why because I am not an expert in the firm or the internal management that the duet firmware do but as far as I can see and understand there is something different in my duet wifi between extruding slow at 30mm/s and 60mm/s that makes not smooth the extrusion at low speeds in straight extruded lines.

Today I ordered a LDO 8 pinion stepper so maybe having more steps per mm (55 insted 44 at full steps) and different inductance and such will help. It will arrive in about two weeks.

-

Seems to me at this point we need to verify if it's a mechanical extruder issue or firmware issue. So we'd either need to change the extruder, or change the firmware.

-

@phaedrux what can I do to change fw? Because the latest test was done with the rc3 and the previous one with the rc2.

Regarding the extruder change it is difficult because it involves a total redesign on the X carriage, maybe I have enough time to adapt it for a bmg again or do you sugest another thing to do and test? -

@zabana said in Vertical banding on COREXY machine:

@phaedrux what can I do to change fw? Because the latest test was done with the rc3 and the previous one with the rc2.

Regarding the extruder change it is difficult because it involves a total redesign on the X carriage, maybe I have enough time to adapt it for a bmg again or do you sugest another thing to do and test?Can you play a bit with the pinch-gear tension while you extrude in free air?

My gut feeling tells me, that the whole BMG-gear pinch geometry is wrong. (on my clones at least)

I pulled filament by hand through the gears of the sherpa mini and noticed, that any increase of pinch ends in a rough movement of filament. The dual gears get pushed together, before I get reasonable clamping on the filament side. The bracket shaft is parallel to the gears, so we can't avoid pushing both sides at once.If I had to re-construct it, I'd turn the idler bracket shaft 90°. That way the pivot point would be along the dual gears and the pinch force would only apply to the filament path.

-

@zabana

Since you are using a sherpa mini too, I think I will reconstruct the front bearing holder with a slightly larger distance between the main shaft and the hole that takes the pinch bracket shaft. The dual gears must not mesh too hard before the filament pinch force is right.

A bit of play between the gears is easier to accept than 'clenched teeth' -

@o_lampe I think I get what you say but can you post a pic or drawing bout what you say exactly?

-

from my experience this issue is a combination of things like geared extruder , short filament path , stiff filament (pla) and tiny melt zone .

try to change one of those and see if you have any improvement . easiest is to change filament to something less stiff like nylon .

first time i saw this type of artifact was when i shortened my filament path by half , all else was the same .