E 3d BIGBOX Duel head

-

@phaedrux

the Z sensor is what came with the printer but i have found the problem and now it works.i have been working on things and here is where i am at now with the printer.

X axis will home by moving to the left (from front of machine) after double bump on end stop

Y axis will home by moving to front of printer but this makes the X axis bounce in its end stop until Y reaches its end stop. this can not be right? can it?

Z axis will home after i flipped the wires so it runs in the up direction and not down.

the bed reads the correct temperature and it does heat but the program stops it from heating saying it is not heating up fast enough. there is a setting for this i assume?

So need to figure out Y axis home issue and heater faulting out because of not heating fast enough.

thank you for your response above it helped me figure out the sensor issue.

any suggettions on these issues?

-

@testpro said in E 3d BIGBOX Duel head:

Y axis will home by moving to front of printer but this makes the X axis bounce in its end stop until Y reaches its end stop. this can not be right? can it?

Not sure what you mean by this. Can you show a video?

@testpro said in E 3d BIGBOX Duel head:

the bed reads the correct temperature and it does heat but the program stops it from heating saying it is not heating up fast enough. there is a setting for this i assume?

You'll need to PID tune the heater.

https://duet3d.dozuki.com/Wiki/Tuning_the_heater_temperature_control -

@phaedrux Getting a video file small enough to upload is a problem at this point.

basically i home x and the carriage goes to the left in the X direction but the Y direction is going to the back of the machine.

Now X is homed and then tell y to home and y moves to the front of the machine and the carriage is bouncing off the X end stop and makes the whole shake until Y hits its end stop on front of machine.

i will try video again

. -

@testpro [0_1622156296017_MAH00089.avi](Uploading 100%)

vidoe shows the shacking or skipping going on while homing to Y.

-

@testpro MAH00089.mp4 ok this should work to show the issue while performing Y homing

-

It would seem that a belt is slipping perhaps.

-

@phaedrux

ok the belt is slipping but because it is forced to.When I home X, the extruder moves to the left but Y moves to back of machine and once X hits endstop it stops but when i then hit Y to home, Y move to front of machine and X is trying to go left but it can not because it is at the end stop and then the popping noise.

So X move right of the machine Y moves to front of machine, This also causes a popping nose but this time Y is at its end stop and can not go any further to front of machin.

So X moves left of the machine Y moves to back of the machine.

so thing is wrong with the way Y is moving in response to X when it moves. which is causing all the popping noise. ???

what do you think

-

Is this machine actually a corexy?

-

@phaedrux i have no idea what CoreXY means.

-

Can you post some photos of the belt path?

I'm not super familiar with the big box and it's variations.

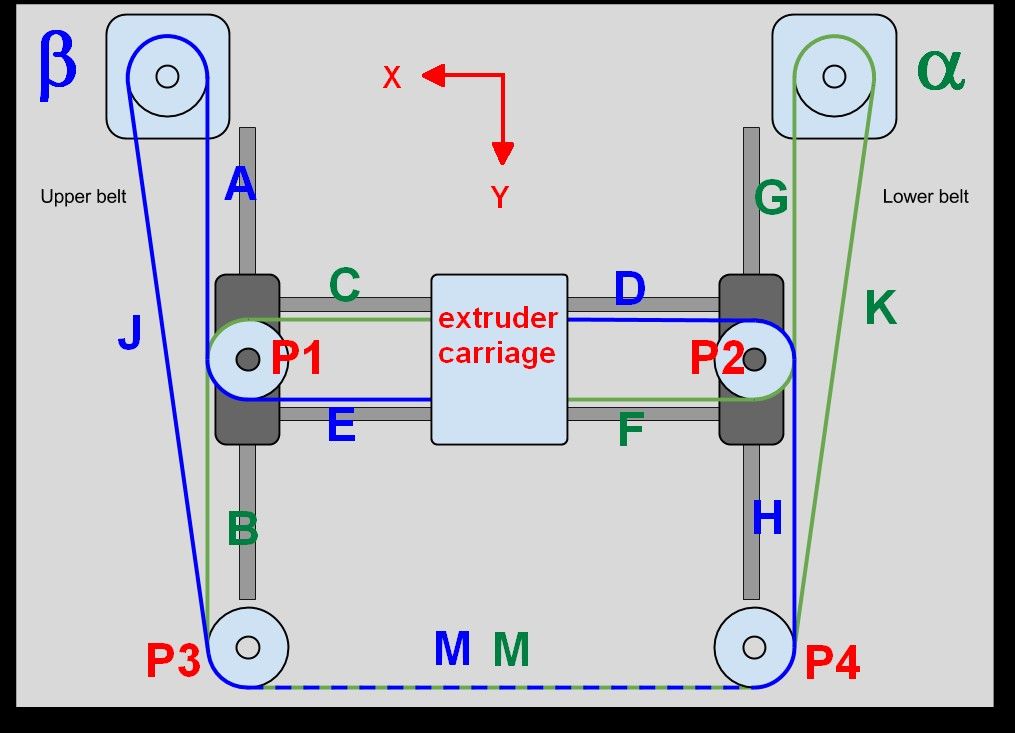

does the belt path look like this?

Somewhat anyway.

-

@testpro ok this printer is a big box e3d printer with 2 heads. only one head is hooked up for now.

this line of code is saying i have the program set for a CoreXY system (M669 K1 ; select CoreXY mode)

is there another option for the code that will take care of this problem i am having?

-

Yes the config is set to corexy, but if the machine isn't actually corexy you'll have some issues.

Corexy is a kinematic arrangement where the motion of 2 motors work together to move the print head. A cartesian printer by contrast only uses a single motor per axis.

If you can get a photo or video of the belt arrangement on XY for me I can tell pretty quickly.

-

@phaedrux Ok so after looking at machine again the Y axis has one belt at each side of the printer (right and left) and the X axis has one belt moving extruder carriage left and right.

so the X stepper motor moves on the y axis on the right hand side of machine when y moves the belt.

i have some photos as well.

-

Ok, so not CoreXY at all. Just standard cartesian.

Delete this line

M669 K1 ; select CoreXY modeand try again with homing. -

@phaedrux

ok i have deleted (M669 K1 ; select CoreXY mode) the whole line and reset the machine and it is still going

the same thing as it was before no change on homing. -

@testpro

ok i went through the set up config to get the core program we are playing with now and i choose the CoreXY feature, would this have set all other files to the CoreXY as well. So we would need to change it in other places or would it be better to go through the process again but this time just pick regular cartesian. would that be the easy way to fix it? -

@testpro If you chose CoreXY in the configuration tool originally, then yes, it would be better to go back through and generate a new set as Cartesian. Can you post a picture of the contents of the sys folder on the SD card? I'm wondering if you have other files left in the folder that may be conflicting. It may be best to delete all the files in the sys folder before uploading the new set.

Also, you can compare your config with the one here, which is a known-working config for an E3d BigBox: https://forum.duet3d.com/post/175431

Ian

-

Homing files should still be ok since they are based on the position of the endstops, but you may need to double check that the motors are turning in the correct direction to move the axis left or right front or back as expected.

-

@droftarts

ok done a comparison and changed several things but result has not changed. So deleted all files new make new files and reload and see what happens. any advice on new files? -

@testpro You could start by using the config.json file from this post in the configuration tool: https://forum.duet3d.com/post/174892

Do this by downloading the json file, then click on 'use existing configuration' in the configuration tool (bottom of first page) and select the json file.

That generated the config set for that machine, and should be mostly right for your machine. The caveat applies that I don't know how different your machine is from that one; for example, it was fitted with an IR probe for Z homing and mesh compensation. So check carefully.

Ian