Ghosting/ringing issues with new custom built core xy

-

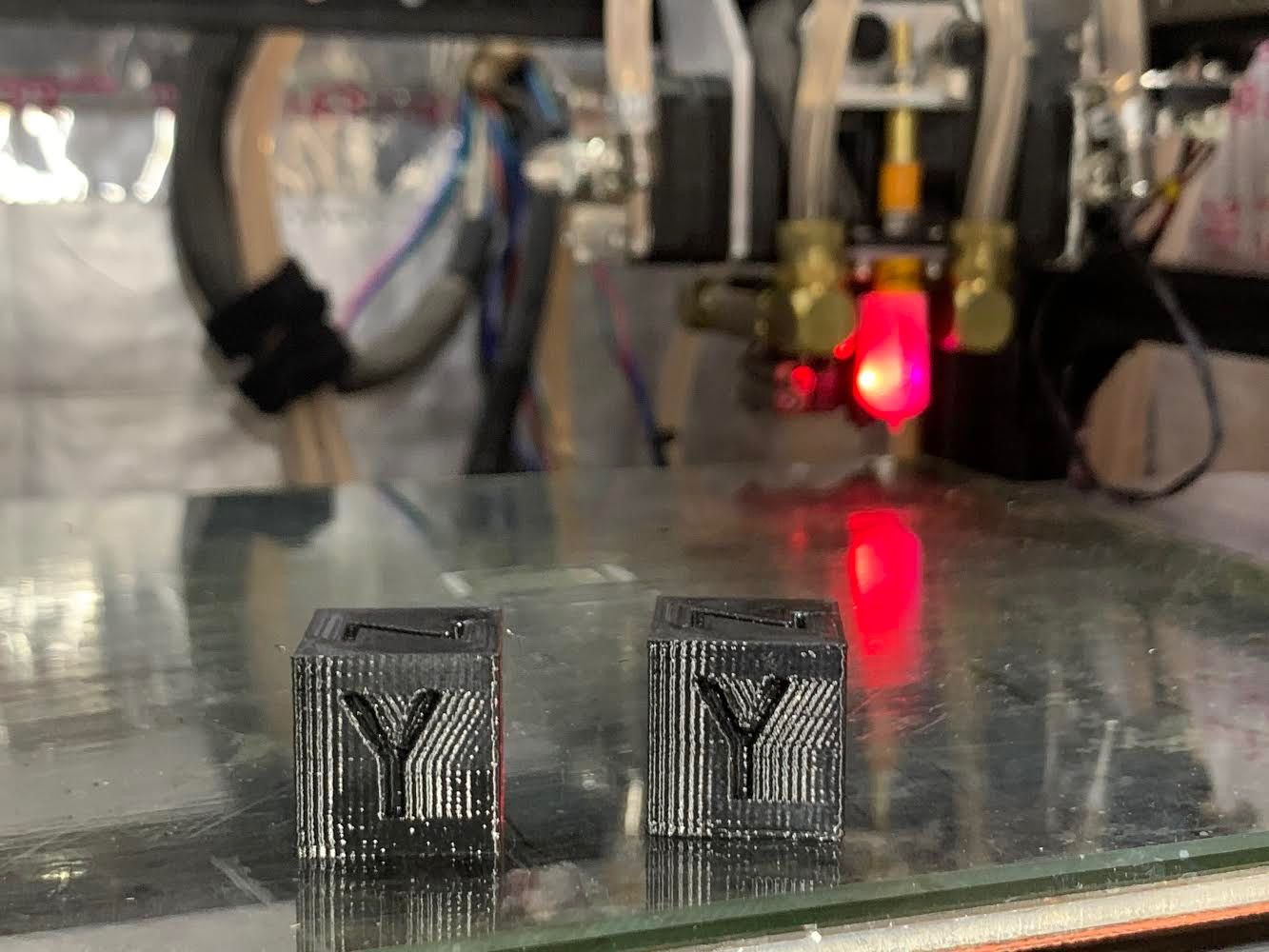

I’ve been struggling to with ghosting/ringing for the last few days so I thought id reach out for some help. I’ve mostly been toying with the acceleration values, the current values are based off the max acceleration calculator I found on sub thread. My retraction settings in cura are set at the nozzle diameter of 0.4 which is what Slice recommends for this configuration. All the stepper drive motors are set at 70% of their max values. Ill post my config below with some pictures of a calibration cube which is hot off the glass and one from earlier today with the original acceleration values nulled in the config. The cubes are from polycarbonate. Any advice would be greatly appreciated, thanks

; Physical Drive connection M569 P0 S0 ; X Drive 0 M569 P1 S0 ; Y Drive 1 M569 P9 S0 ; Z1 Drive 8 M569 P8 S0 ; Z2 Drive 9 "U" M569 P3 S1 ; Ex Drive 3 M569 P4 S0 ; Ex Drive 4 M584 X0 Y1 Z8:9 U9 E3:4 P3 ; Driver 0=X motor, D1= Y motor, D8:9 = Z motors, D3:4 E motors M671 X110.625:345.625 Y117.5:117.5 S2 ; Leadscrews at left (connected to Z) and right (connected to E1) of X axis M350 E16:16 I0 ; configure microstepping without interpolation M350 X16 Y16 Z16:16 U16 I1 ; configure 16x microstepping with interpolation M92 X80.00 Y80.00 Z800.00:800.00 U800 E415.00:415.00 ; set steps per mm ;M566 X900.00 Y900.00 Z12.00:12.00 U12.0 E800.00:800.00 ; set maximum instantaneous speed changes (mm/min) ;M203 X12000.00 Y12000.00 Z1000.00:1000.0 U1000.0 E8000.00:8000.0 ; set maximum speeds (mm/min ;M201 X2000.00 Y2000.00 Z20.00:20.0 U20.0 E500.00:500.00 ; set accelerations (mm/s^2) ;----Experimental Settings---- M566 X600 Y600 Z30:30 U30 E3000:3000 ; Set maximum instantaneous speed changes (mm/min) M203 X15000 Y15000 Z1500:1500 U1500 E6000:6000 ; Set maximum speeds (mm/min) M201 X4358.98 Y4358.98 Z100:100 U100 E10000:10000 ; Set accelerations (mm/s^2) x/y:3000 :----------------------------- M906 X1400.00 Y1400.00 Z1400.00:1400.00 U1400.00 E800.00:800.00 I30 ; motor currents: 70% max (mA) and motor idle factor in per cent M84 S30 ; Set idle timeout ; Axis Limits M208 X-23 Y0 Z0 U0 S1 ; set axis minima M208 X220 Y220 Z275 U275 S0 ; set axis maxima ; Endstops M574 X1 S1 P"xstop" ; configure active-high endstop for low end on X via pin xstop M574 Y1 S1 P"ystop" ; configure active-high endstop for low end on Y via pin ystop M574 Z1 S2 ; configure Z-probe endstop for low end on Z ; Z-Probe M950 S0 C"duex.pwm5" ; create servo pin 0 for BLTouch M558 P9 C"^zprobe.in" H5 F120 T6000 ; set Z probe type to bltouch and the dive height + speeds G31 P500 X0 Y0 Z1.016 ; set Z probe trigger value. Prev Value: 1.283 M557 X20:200 Y0:130 S20 ; define mesh grid ;Bed Heater M308 S0 P"bedtemp" Y"thermistor" T100000 B3950 ; configure sensor 0 as thermistor on pin bedtemp M950 H0 C"bedheat" T0 ; create bed heater output on bedheat and map it to sensor 0 M307 H0 B1 S70.00 ; enable bang-bang mode for the bed heater and set PWM limit M140 H0 ; map heated bed to heater 0 M143 H0 S199 ; set temperature limit for heater 0 to 199C ;Tool 0 Heater M308 S2 P"duex.e2temp" Y"pt1000" R4700 ; configure sensor 2 as PT1000 on pin duex.e2temp M950 H2 C"duex.e2heat" T2 ; create nozzle heater output on duex.e2heat and map it to sensor 2 M307 H2 B0 S1.00 ; disable bang-bang mode for heater and set PWM limit M143 H2 S500 ; set temperature limit for heater 2 to 500C ;Tool 1 Heater M308 S1 P"duex.e3temp" Y"pt1000" R4700 ; configure sensor 1 as PT1000 on pin duex.e3temp M950 H1 C"duex.e3heat" T1 ; create nozzle heater output on duex.e3heat and map it to sensor 1 M307 H1 B0 S1.00 ; disable bang-bang mode for heater and set PWM limit M143 H1 S500 ; set temperature limit for heater 1 to 500C ;Chamber Heater M308 S3 P"duex.e4temp" Y"thermistor" T100000 B3950 ; configure sensor 3 as thermistor on pin duex.e4temp M950 H3 C"duex.e4heat" T3 ; create chamber heater output on duex.e4heat and map it to sensor 3 M307 H3 A11 C99000 D2000 B1 ; chamber heater operates in bang-bang mode ;M307 H3 B1 S1.00 ; enable bang-bang mode for the chamber heater and set PWM limit M141 H3 ; map chamber to heater 3 M143 H3 S150 ; set temperature limit for heater 3 to 150C ;Circulator Pump (24v) M950 F0 C"fan1" Q500 ; create fan 0 on pin fan1 and set its frequency M106 P0 S.9 L.6 X.8 H1:2:3 T45 C"Circulator Pump" ; set fan 0 value. Thermostatic control is turned off ;Radiator fans (3:120mm @ 12v) M950 F1 C"duex.fan3" Q500 ; create fan 1 on pin duex.fan3 and set its frequency M106 P1 S1 L.3 X1 H1:2:3 T45 C"Radiator fans" ; set fan 1 value. Thermostatic control is turned off M950 F1 C"duex.fan4" Q500 ; create fan 2 on pin duex.fan4 and set its frequency M106 P1 S1 L.3 X1 H1:2:3 T45 C"Radiator fans" ; set fan 1 value. Thermostatic control is turned off M950 F1 C"duex.fan5" Q500 ; create fan 3 on pin duex.fan5 and set its frequency M106 P1 S1 L.3 X1 H1:2:3 T45 C"Radiator fans" ; set fan 1 value. Thermostatic control is turned off ; Tool 1 M563 P0 S"Extruder 1" D1 H2 F0f:1 ; define tool 1 G10 P0 X0 Y0 Z0 ; set tool 1 axis offsets G10 P0 R250 S0 ; set initial tool 1 active and standby temperatures to 250C ; Tool 0 M563 P1 S"Extruder 2" D0 H1 F0:1 ; define tool 0 G10 P1 X15 Y0 Z0 ; set tool 0 axis offsets G10 P1 R250 S0 ; set initial tool 0 active and standby temperatures to 250C ; Miscellaneous M911 S12 R20 P"M913 X0 Y0 G91 M83 G1 Z3 E-5 F1000" ; set voltage

-

Are those steel core belts? They tend to be pretty stretchy and can break when used with tight bend radiuses. That might be part of the cause.

Very high acceleration can also trigger a lot of ringing. 4358 with a heavy print head is pretty high.

Those test cubes are also tiny. Unless they are representative of what you'll eventually be printing you might want to double or triple their size so you can get a better idea of performance on actual prints.

You can also look into DAA and input shaping.

https://duet3d.dozuki.com/Wiki/Gcode#Section_M593_Configure_DAA_or_Input_Shaping

-

With something that consistent, I'd first be looking at your belts/idlers. like phaedrux said, Steel core likes to suddenly break when you're not looking at it

Second, it might be a stuck idler which will have a unique period. Try printing a 60x60 cube or something to see how long your ripples go.I run a gantry that's probably juuuust under that weight at 7k acceleration - what were your previous values? Can you turn down the acceleration and escape the ringing?

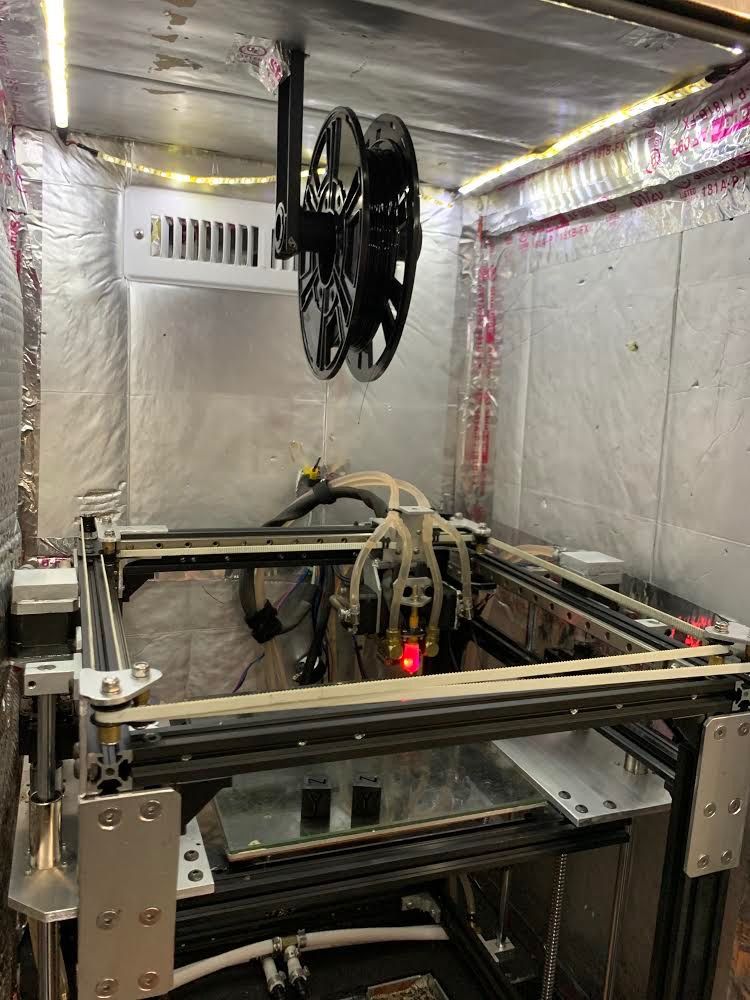

More pictures of your setup, your joints, how the pulleys are arranged, etc will be helpful in diagnosing the issues.

-

@phaedrux Thanks for the feedback I really appreciate it. I run the steel core belts because I'm usually printing at 100C or more so they seem to hold up better with the heat. Should I try halving the acell? I noticed before I went to work this morning my max speed was way too high I dropped that from 15000 to 7500 and that made a big difference, printed another cube and cut the ringing down substantially on the X axis. I also notice the bed wobbling a little so I took the springs out and switched to some solid silicone bed mounts.

-

@luke-slaboratory The previous values where nulled out commands above the experiment section. I fabricated all the bracing and bare aluminum components, plus the smaller pre-made 2020 braces. I feel like the frames pretty solid, I used bronze spacers and thrust washers on the pulleys and they seem pretty smooth. Are the jerk values reasonable? should I drop the accel 3500-ish? I posted some pictures, sorry its hard to get any other angles it being inside the enclosure.

-

https://www.filastruder.com/products/gates-2gt-belts-high-temperature-epdm

Gates high temp belts good to 135c. Just say no to steel core.

-

@phaedrux thanks for the link I’ll order some up next week