Fans vs Berd-Air

-

i found that

70% of berd-air noise is from pump air flow

30% is from the motorthere are simple solutions for both

Motor noise

use flex mount. for myself i made this one

there are other mounts with even vibration-canceling ones, but require more space. most simple solution (even no print needed) is to hang the motor on the rubber band

AND use 22500 Hz PWM frequency. as a bonus this trick also keeps pump motor cold

Pump airflow noise

use silencers my design makes it silent. very silent. it is a bit tricky to print, but once printed, you will be surprised

-

@klcjr89 The flow rate in the data you posted is in H/L which I read as Hours per Litre. I'm assuming that's a typo and should be Litres/Hour. (Or does it really take >600 hours to shift one Litre of air

).

). -

-

ok, so this is an old post, but it seems to be the most popular on google and useful. Does anyone have any reports on how their berd air systems have held up over time? Have they been excellent or a waste of time? How is their reliability?

Does anyone have any followup data on the brushless aliexpress pump listed? It looks like the choice I am most tempted by at the moment.

-

@Phaedrux said in Fans vs Berd-Air:

@c310 said in Fans vs Berd-Air:

my design

Link is broken.

Hey look the link is working now.

-

@lael I just picked up a brushed system from the makerhive. Much cheaper than the brushless option. I might see if I can make the pump brushless at some point, but for now it's working great. I made my own air mount with some brass tube from Lowe's. Quieter and much easier to work with.

-

@Surgikill I'm curious what size brass tubing you use? I've tried using small hobby brass tubing and even packing the tube with salt powder it would still collapse in on itself in bad ways when i'd try to bend it. I'd much rather use brass than aluminum since the brass would deform without tearing/ breaking as easy as the aluminum, and the akuminum gets more break prone after exlosure to hotend buuut i have not been able to shape it without issues.

-

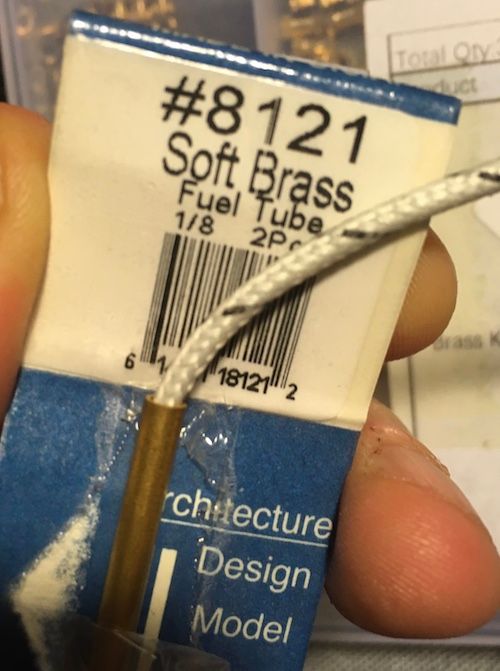

@lord-binky don't use salt, use electric wire. Put it in the tube, bend it and pull the wire. For example, iirc, K&S soft brass (something like 8121) tube is a perfect match for heater cartridge electric wire gauge.

Edit: yes heater cartridge cable perfect fit 8121 K&S soft brass tube

-

@lord-binky said in Fans vs Berd-Air:

@Surgikill I'm curious what size brass tubing you use? I've tried using small hobby brass tubing and even packing the tube with salt powder it would still collapse in on itself in bad ways when i'd try to bend it. I'd much rather use brass than aluminum since the brass would deform without tearing/ breaking as easy as the aluminum, and the akuminum gets more break prone after exlosure to hotend buuut i have not been able to shape it without issues.

Invest in a small tube bender (min version of what plumbers use to bend pipes). Something like this https://www.amazon.co.uk/Tubing-Bender-Degrees-Manual-Bending/dp/B088H1MHWN/ref=sr_1_7?adgrpid=119993429162&dchild=1&gclid=Cj0KCQjwi7yCBhDJARIsAMWFScPk-xcgly9PRIz5mgxBPKlnamYT_OstJqT7pmfj1g5J3HHZ2Dz1Xs8aAohjEALw_wcB&hvadid=501516551233&hvdev=c&hvlocphy=9046150&hvnetw=g&hvqmt=e&hvrand=14776184315352084993&hvtargid=kwd-295847543910&hydadcr=1596_1935511&keywords=small+tube+bender&qid=1615808871&sr=8-7

-

@lord-binky I didn't bend the tube. I just made jigs to drill it, then glued it into a tusk mount.

-

Thanks, I'll try again with some of the cloth covered wire and see if that won't get stuck. I used jig's and spring tube benders which worked ok for the aluminum but that brass I tried before was just determined to fold in on itself.

-

A wild suggestion ... try freezing some water in it and then do the spring tube bender thing. I have not tried that myself, just read about it.

-

try tube bender https://www.thingiverse.com/thing:2869014

and my tube drilling mask https://www.thingiverse.com/thing:3608733

perhaps other berd-air useful parts :

Silencer https://www.thingiverse.com/thing:3429324

motor holder https://www.thingiverse.com/thing:3429374