486MP Adhesive Removal

-

A cheap mix of orange oil (d-limone) and IPA worked for me getting a very sticky thick adhesive used to hold a Teflon sheet down that acted as a slide sheet for a cnc machine we service .

IPA and methyl spirits on there own didn't work , adhesive kept grabbing the scrape tool or cloth .

but a 10% orange oil in IPA solution suddenly turned it into soft bubbly scrape-able goo with in minutes.

another trick I have used on industrial label adhesives ( Wine bottle labels to be exact) but takes a 3-6 days to work is just spread margarine (not butter or peanut butter) over it and let it sit .

-

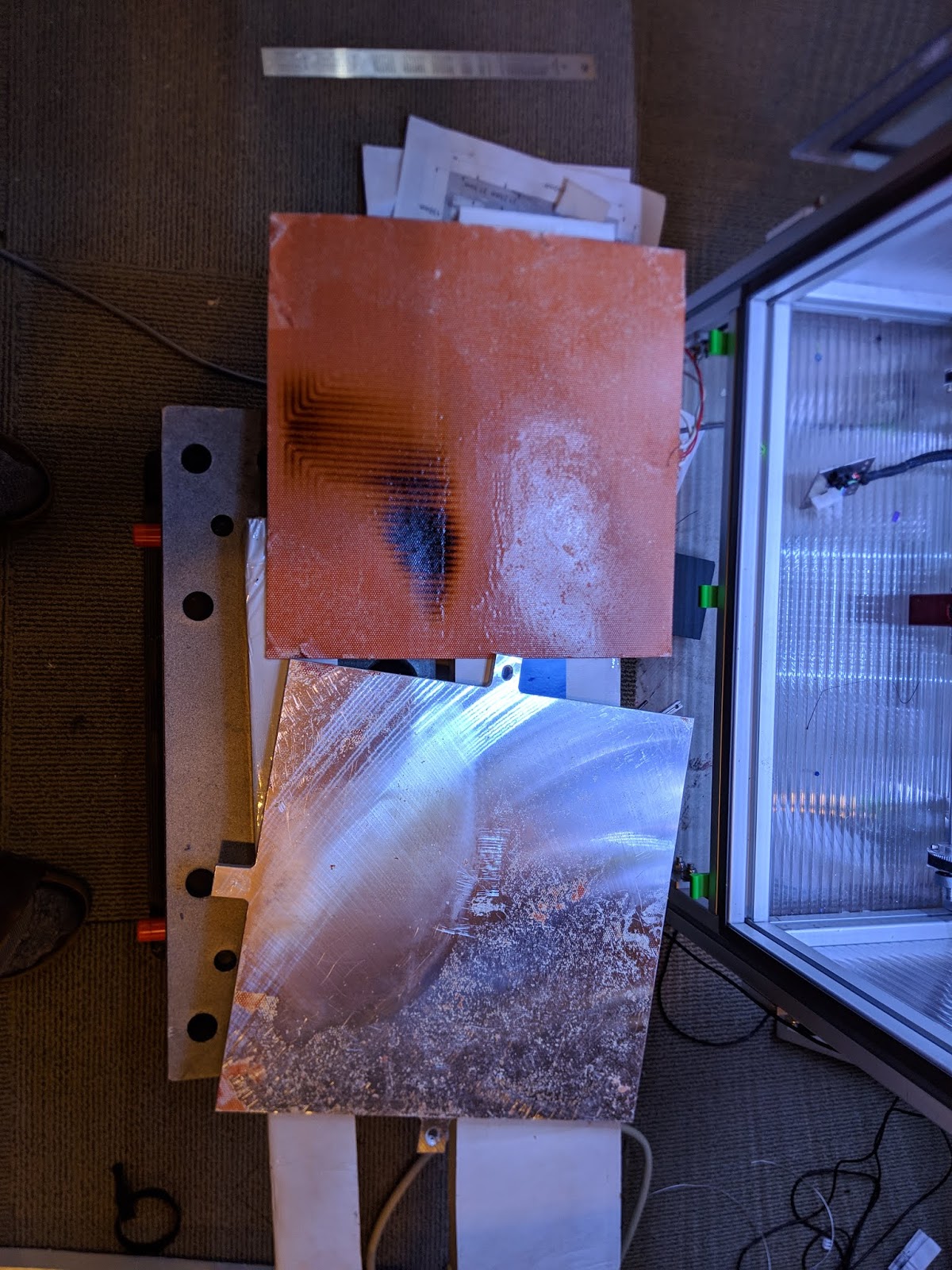

Same issue, Heater let go.

Do not think peanut butter is going to sort this one!

Honestly think this is a heater issue as the other 3/4 is fine.

-

@PaulHew How was that heater pad bonded to the plate?

-

@Phaedrux 3M 468MP, it is preapplied to the heater.

never had a heater let go like that. Even the guys in the RC / Voron discord were surprised.

-

@PaulHew Yeah that's scary. I wonder how many fire hazards like that are out there like ticking time bombs. I'm glad I took the time to scrape it off mine and use silicon adhesive instead.

-

Weather the adhesive failed and the lost cooling caused the heater to overheat or if the heater itself failed won't be easy to determine? BigCliveDotCom or AvE autopsy?

-

@gaweyo Well the burn mark on the heater where it wasn't making contact seems a dead giveaway.

-

I've posted this picture before- heater let go of the plate in my printer after about 2 years of service:

I didn't seal the edges of the heater with silicone as Keenovo recommends (I had never seen a recommendation before I used the heater). It looks like @PaulHew did and the heater let go anyway.

The replacement heater was glued down with silicone instead of 468MP. It's been on there almost 2 years and doesn't show any sign of letting go.

-

@mrehorstdmd

How do you apply the silicone-glue evenly?

The stuff, I have here from Auto-store has pretty low viscosity.

A silicone heater is stiffer than a PEI sheet, but still able to get wavy without an even layer of silicone-glue.

And the wavy part could cause a cold-zone on the bed surface. ( Maybe only in my imagination) -

I never much fancied the idea of relying on an adhesive bond for the bed heater. That's another reason why I used semi rigid insulation between the build platform frame, and the aluminium build plate (with heater attached). The heater matt is effectively clamped between the insulation and the aluminium plate so if the adhesive fails, it won't make much difference.

-

@o_lampe said in 486MP Adhesive Removal:

How do you apply the silicone-glue evenly?

could use a comb like tool, much like the used when laying down cement based adhesive for tiles?

-

@Phaedrux said in 486MP Adhesive Removal:

@gaweyo Well the burn mark on the heater where it wasn't making contact seems a dead giveaway.

chicken and egg? did the heater overheat causing the adhesive to fail, or did the adhesive fail causing the heater to overheat?

result is the same in either scenario, yes.

-

@gaweyo said in 486MP Adhesive Removal:

@o_lampe said in 486MP Adhesive Removal:

How do you apply the silicone-glue evenly?

could use a comb like tool, much like the used when laying down cement based adhesive for tiles?

That's what I did. Then used a rolling pin to push the pad down onto the plate from one edge and rolled out any air. Then rolled it down firmly. Added a bead around the edge and smoothed it out. Then stacked a board and a bunch of filament boxes on top for a couple days to let it cure. It's been going for 3 almost 4 years now I think.

Hard to see because the silicon is clear, but it's smeared around the edges. I used orange oil cleaner to remove the 486.

This was posted earlier but bears repeating.

https://keenovo.store/blogs/how-to/how-to-remove-from-a-3m-adhesive-backing-installation

Sometimes, you may need to remove a heater pad installed with an adhesve backing. Here below could be some helpful tips for this:

- Warm the adhesives.

- Use a fishing line to cut through the adhesive, start from each corners, little by little.

- Clean and remove the residue with citrus cleaner ( please follow cleaner instructions).

- Use high temperature silicone RTV sealant(usually a red paste) to adhere the heater pad to the new aluminum or glass plate. ( a thin layer will do and please make sure of no air bubble trapped).

- Apply a thick bead of the sealant around the edges of the heater pad.

- Add some pressure on the heater pad surface evenly and let it cure thoroughly( please follow RTV sealant instructions for the time required in the curing process.)

You may use a thin sharp blade for the cutting if a fishing line is not available.

Care must be taken to not cut into the heater pad. -

By the way - I recently had to remove some PEI that was stuck with 486MP from my plate - some good 80% IPA was good at removing.

-

Hi gtj0,

Just had to do the same as my 16 x 16" PEI sheet came with 4 x 8" 3M sheets and what a mess it became.

I used masking tape, press it down, run a roller over it leave it for ten minuets, then slowly and low to the surface pull the tape back on itself to remove and the 3m mostly comes of with the tape.

Dizzwold.

-

I recently recemented the PEI sheet on my printer's bed. I used an orange based paint stripper to remove the old adhesive from the plate- just brush it on, leave it sit for about 30 minutes and use a plastic scraper to clean it all off the plate. After I stuck the PEI sheet down again I added a bead of silicone around the edge to try to seal it. I'll know if it extends the life of the adhesive in about 2-3 years.