1LC and BLTouch

-

if the red LED in BLTOUCH flashes at 80% duty right after the 3D printer is switched on, please release it with S60 or S160.

-

I am not sure what you mean by 80% duty... The LED is just blinking fast and is very dim. Does this mean the LED is at 80% power? If so, then no, it is much dimmer than that, more like 50% power (as that is another option in the manuel).

-

did you send the servo commands?

-

I ran these...

M280 P9 S60

M280 P9 S160

M280 P9 S10

M280 P9 S90

M280 P4 S160

M280 P4 S60

M280 P4 S120

M280 P4 S10

M280 P4 S90BLTouch is only blinking the RED LED fast at low power.

-

-

-

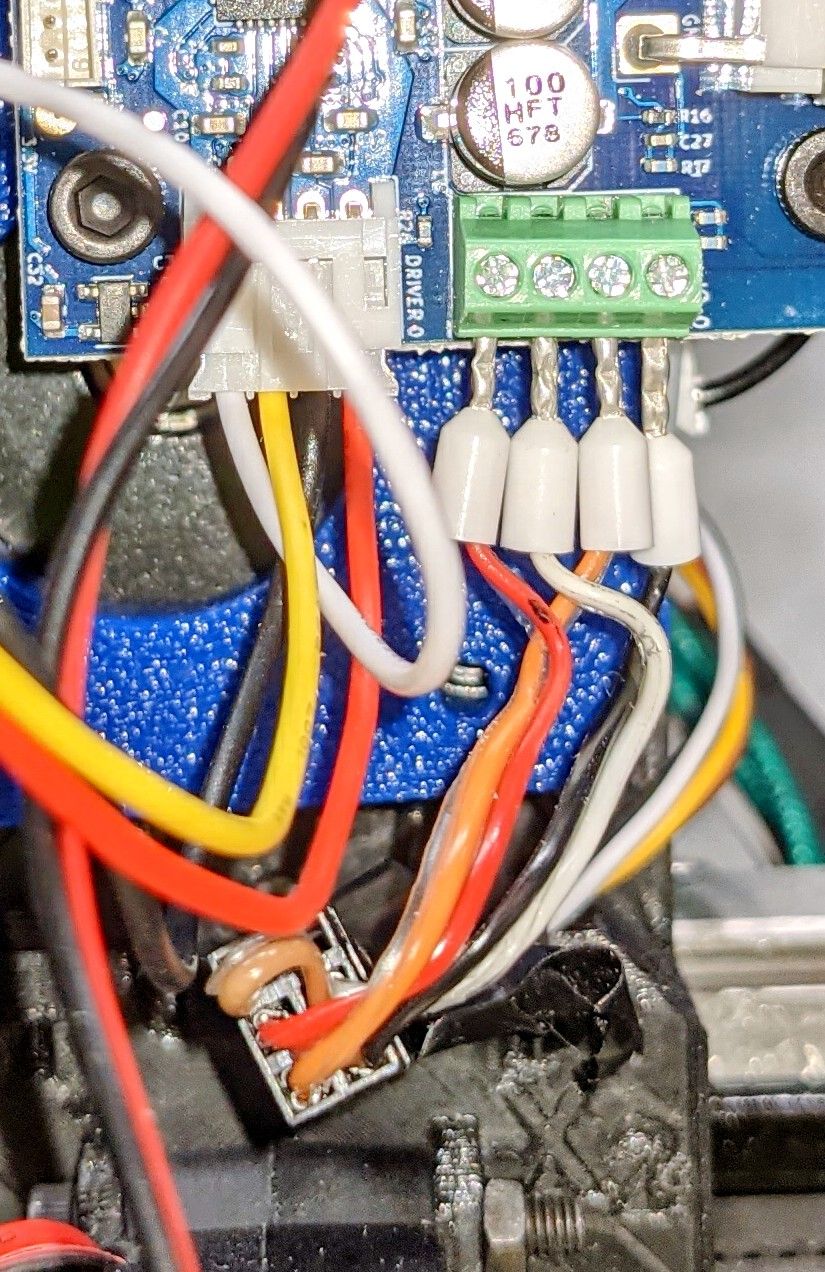

can you post a picture of your wiring?

-

Thought now is that in/out pins are reversed?

-

is the blackwire not ground?

that is connected to io.out

-

Yes... that is what it looks like I did. After I uploaded the pictures, I was looking at my notes and fixed it.

See what happens momentary... That's what I get for wiring the BLTouch by feel, as I didn't have good visibility, was awkward when I wired it. -

unrelated but don't do that

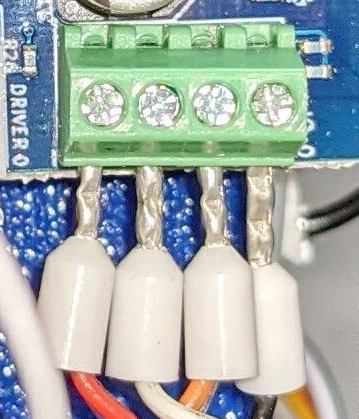

cut the crimped thingies out and stick the wire directly in the connector. Those are just for high currents.

-

@matt3o Crimps are not always for high currents. Bare multistranded wire likes to not go in cleanly.

-

@BlueDust said in 1LC and BLTouch:

That's what I get for wiring the BLTouch by feel, as I didn't have good visibility, was awkward when I wired it.

Looks good now!

Except for M280 P0 S160 doesn't reset/pull the pin up.

-

@Stephen6309 okay, let's just say that those connectors are not made for crimps

-

Once I have this all permanently wired, I planned to cut them down to size so they fit in cleanly. Will have to squeeze the white barrel to flatten it a bit... And yes, they are all stranded wires. Would prefer to keep them neat, and not worry about a runaway wire touching another terminal.

-

@BlueDust you can always put some solder on the tips (ONLY on low currents like those)

-

@matt3o

There is obviously not a lot of room between the screw terminals to fit them properly. -

@matt3o

That is an idea... Thanks. Will consider it when it comes time to re-wire and make this a permanent setup. -

@matt3o said in 1LC and BLTouch:

@BlueDust you can always put some solder on the tips (ONLY on low currents like those)

I'd say that's not a good idea. The solder tin doesn't compress at all like the wire strands would, so you might be get very good pressure. Back to same problem as using the bootlace ferrules.

Give the bare wires a twist with your fingers to keep them tidy and then screw them down.

-

Another way to connect to those screw terminal is to insert a 0.1 pin header in there and use the approtiate connector to connect the header you installed. Don't use this for the hotend.