1LC and BLTouch

-

M122 B10

Diagnostics for board 10:

Duet TOOL1LC firmware version 3.2 (2021-01-05)

Bootloader ID: not available

Never used RAM 4032, free system stack 96 words

HEAT 90 CanAsync 89 CanRecv 83 TMC 54 MAIN 208 AIN 64

Last reset 00:09:36 ago, cause: power up

Last software reset data not available

Driver 0: position 0, 830.9 steps/mm, standstill, SG min/max 0/0, read errors 0, write errors 0, ifcnt 13, reads 25874, writes 13, timeouts 0, DMA errors 0

Moves scheduled 0, completed 0, in progress 0, hiccups 0

No step interrupt scheduled

VIN: 23.8V

MCU temperature: min 22.4C, current 34.6C, max 34.6C

Ticks since heat task active 94, ADC conversions started 573892, completed 573891, timed out 0

Last sensors broadcast 0x00000001 found 1 97 ticks ago, loop time 0

CAN messages queued 6626, send timeouts 0, received 5100, lost 0, free buffers 36 -

@BlueDust it means that you have a version equal or below 1.3

-

@Veti said in 1LC and BLTouch:

bootloader

I was following the instructions to update the bootloader after I was given the link (and saw that no version was listed).

M997 B10 S3

Board 10 starting bootloader updateI never receive a complete message.

After about a minute, I checked m122 again.

Bootloader ID: SAMC21 bootloader version 2.2 (2021-01-16b1)BLTouch is still not working... Even after rebooting...

Red LED blinking fast/dim, and Self Test does not do anything.M122 B10 Diagnostics for board 10: Duet TOOL1LC firmware version 3.2 (2021-01-05) Bootloader ID: SAMC21 bootloader version 2.2 (2021-01-16b1) Never used RAM 4032, free system stack 88 words HEAT 90 CanAsync 89 CanRecv 83 TMC 54 MAIN 218 AIN 64 Last reset 00:01:15 ago, cause: VDD brownout Last software reset data not available Driver 0: position 0, 830.9 steps/mm, standstill, SG min/max 0/0, read errors 0, write errors 0, ifcnt 13, reads 37680, writes 13, timeouts 0, DMA errors 0 Moves scheduled 0, completed 0, in progress 0, hiccups 0 No step interrupt scheduled VIN: 23.8V MCU temperature: min 33.0C, current 34.4C, max 34.4C Ticks since heat task active 168, ADC conversions started 75218, completed 75216, timed out 0 Last sensors broadcast 0x00000001 found 1 171 ticks ago, loop time 0 CAN messages queued 619, send timeouts 0, received 595, lost 0, free buffers 36 -

if the red LED in BLTOUCH flashes at 80% duty right after the 3D printer is switched on, please release it with S60 or S160.

-

I am not sure what you mean by 80% duty... The LED is just blinking fast and is very dim. Does this mean the LED is at 80% power? If so, then no, it is much dimmer than that, more like 50% power (as that is another option in the manuel).

-

did you send the servo commands?

-

I ran these...

M280 P9 S60

M280 P9 S160

M280 P9 S10

M280 P9 S90

M280 P4 S160

M280 P4 S60

M280 P4 S120

M280 P4 S10

M280 P4 S90BLTouch is only blinking the RED LED fast at low power.

-

-

-

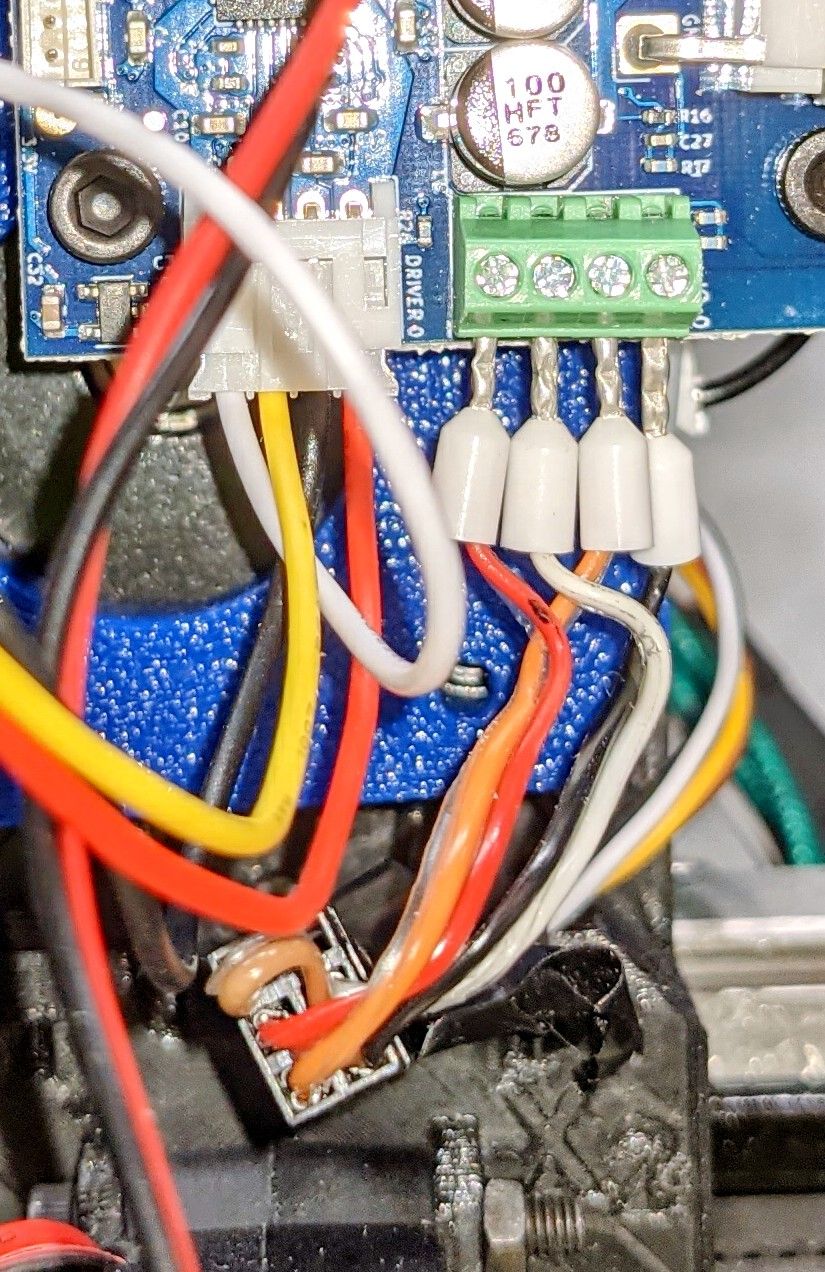

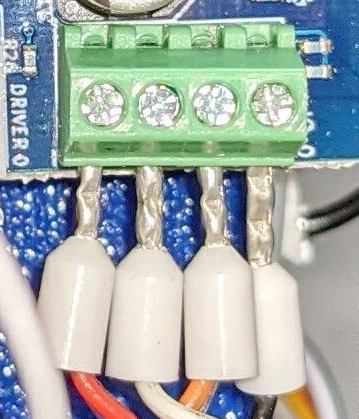

can you post a picture of your wiring?

-

Thought now is that in/out pins are reversed?

-

is the blackwire not ground?

that is connected to io.out

-

Yes... that is what it looks like I did. After I uploaded the pictures, I was looking at my notes and fixed it.

See what happens momentary... That's what I get for wiring the BLTouch by feel, as I didn't have good visibility, was awkward when I wired it. -

unrelated but don't do that

cut the crimped thingies out and stick the wire directly in the connector. Those are just for high currents.

-

@matt3o Crimps are not always for high currents. Bare multistranded wire likes to not go in cleanly.

-

@BlueDust said in 1LC and BLTouch:

That's what I get for wiring the BLTouch by feel, as I didn't have good visibility, was awkward when I wired it.

Looks good now!

Except for M280 P0 S160 doesn't reset/pull the pin up.

-

@Stephen6309 okay, let's just say that those connectors are not made for crimps

-

Once I have this all permanently wired, I planned to cut them down to size so they fit in cleanly. Will have to squeeze the white barrel to flatten it a bit... And yes, they are all stranded wires. Would prefer to keep them neat, and not worry about a runaway wire touching another terminal.

-

@BlueDust you can always put some solder on the tips (ONLY on low currents like those)

-

@matt3o

There is obviously not a lot of room between the screw terminals to fit them properly.