Problem with rear side of Test Cube

-

@dmbgo said in Problem with rear side of Test Cube:

Printing now

I will check back in a bit.

Frederick

-

Where are you Fredrick? If it is too late at night, we can leave it until tomorrow.

-

@dmbgo I'm here.

Frederick

-

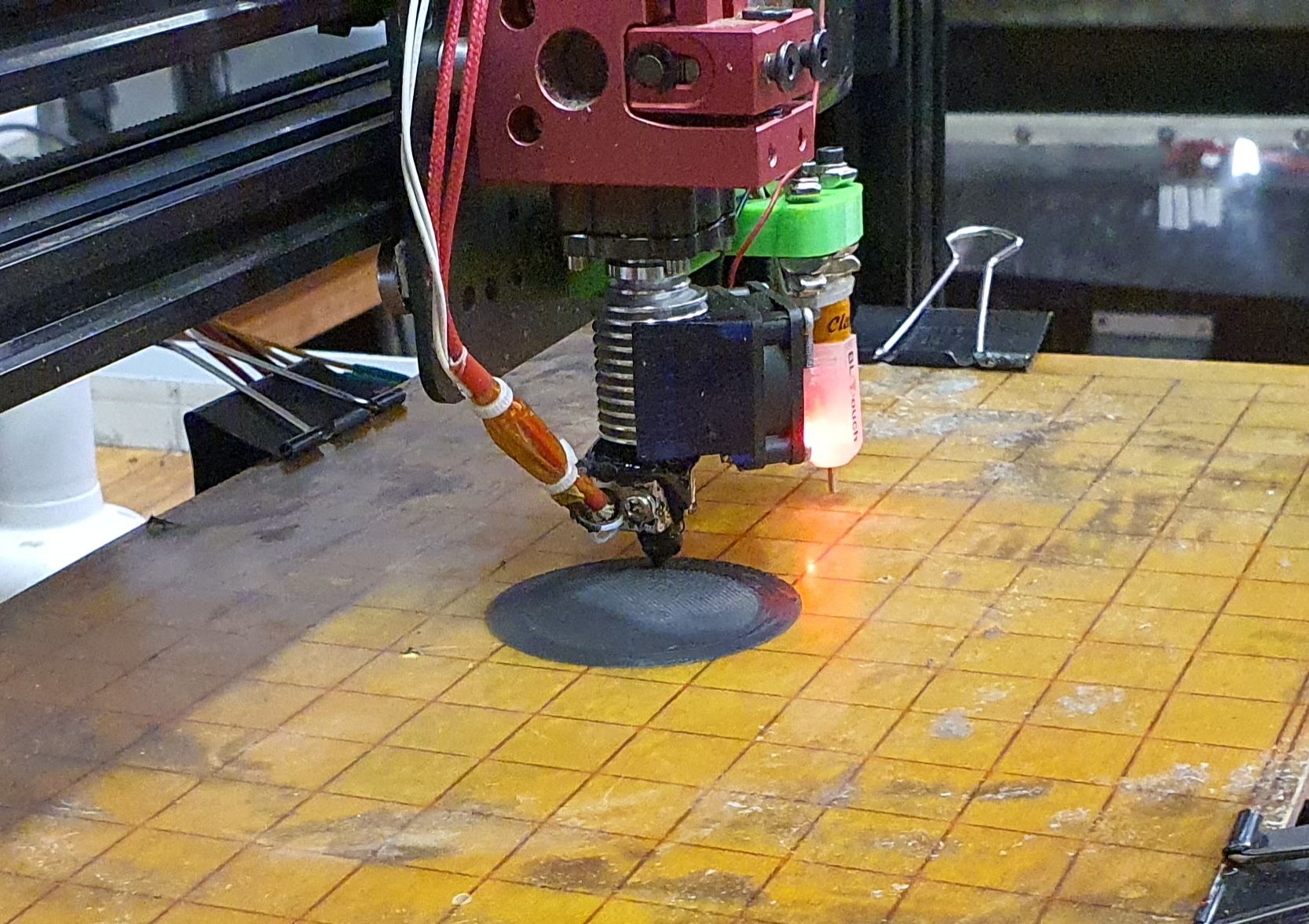

The disk is printing at 30 mm/s. It will probably take about 20mins more.

-

@dmbgo said in Problem with rear side of Test Cube:

The disk is printing at 30 mm/s. It will probably take about 20mins more.

What does it look like so far?

Frederick

-

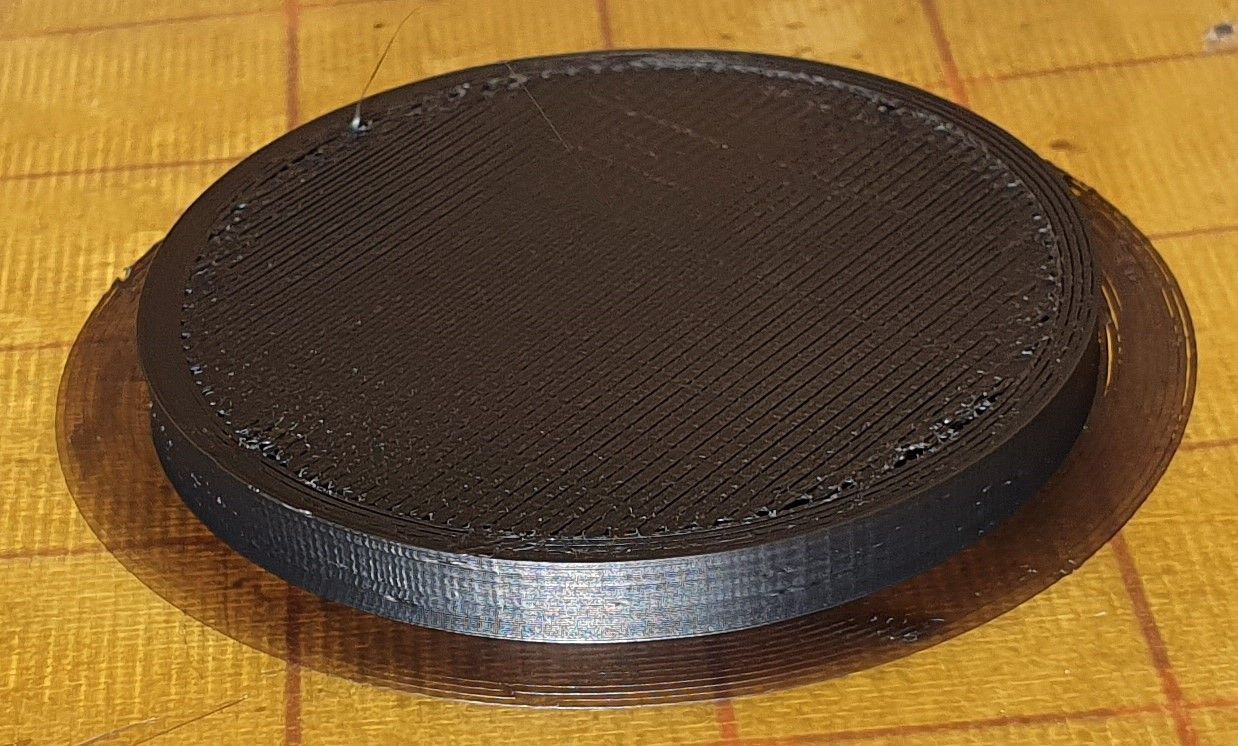

-

OK.

I'll check back in 15 mins.

Frederick

-

The bed levelling is a bit out now, but I dont think it will affect the disc

-

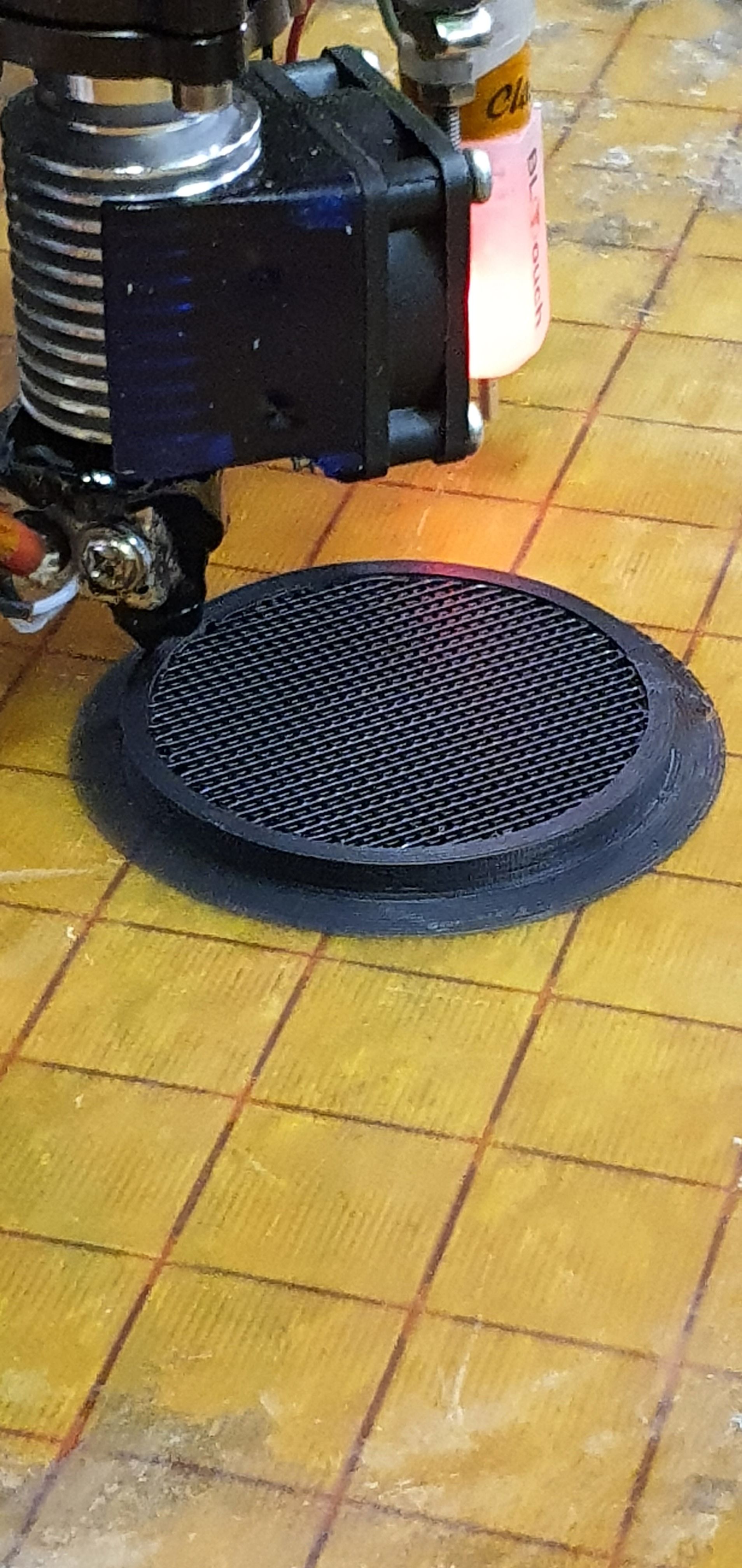

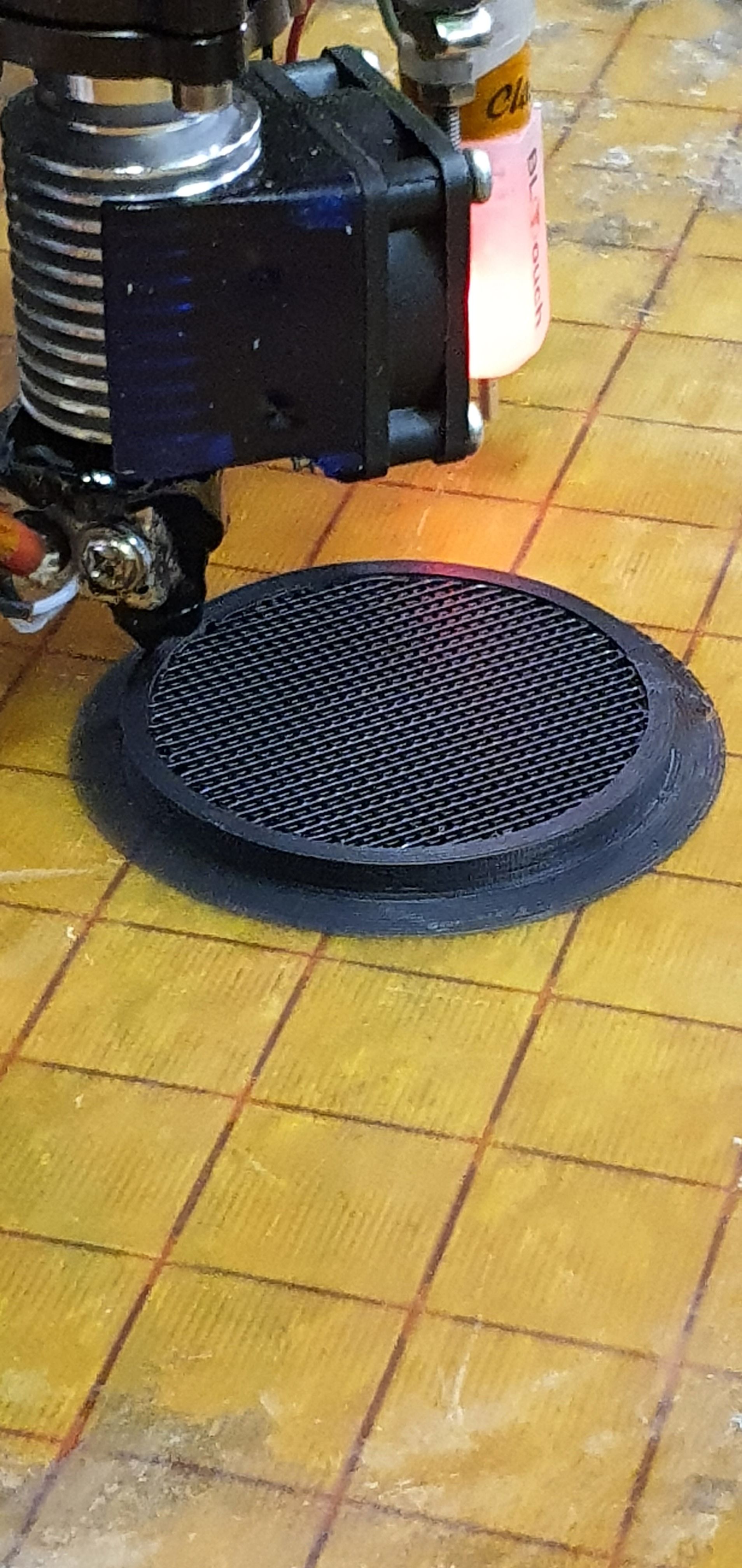

Almost there...

-

@dmbgo said in Problem with rear side of Test Cube:

Almost there...

It's going as I expected.

Frederick

-

Just covering the top now.

-

is your bed level? looks like the nozzle is closer on one side of the print than the other. a bad first layer can make trouble for the rest of the print in abs, especially if you are printing small items with short layer times. I would try leveling the bed so the first layer looks perfect and printing 2 test cubes instead of one to give each layer enough time to cool off before the next layer hits. I forgot to ask how ridged is your carriage? is there any play or slop in any direction?

-

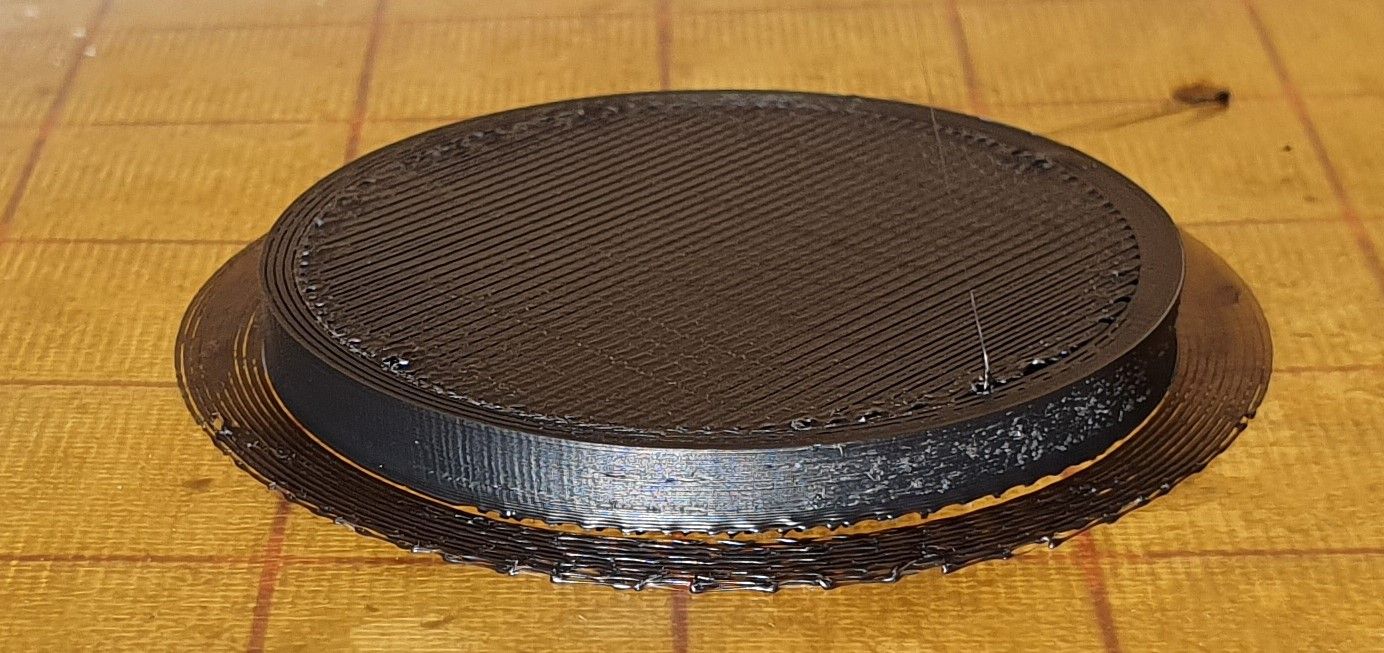

Fredrick, it has printed.

-

@dmbgo said in Problem with rear side of Test Cube:

Fredrick, it has printed.

I think you may just be seeing ABS shrinkage.

You do have a bed adhesion issue on one section and I imagine you can see that.

If you have some PLA perhaps print the same object and see what you get.

Have you got any PETG you could try? It's a good alternative to ABS and it doesn't have the kind of shrinkage issue that ABS has.

Frederick

-

@antlestxp,

The bed isn't level atm, the bed is usually level though, I just wanted to get the disk printed before it was too late for Fredrick.I will now try printing 2 x test cubes at once, since, as you say it might be caused by the print failing to cool fast enough.

-

@dmbgo said in Problem with rear side of Test Cube:

I will now try printing 2 x test cubes at once, since, as you say it might be caused by the print failing to cool fast enough.

You don't want ABS to cool fast - that exacerbates the shrinkage issue. That's why I said to print this test with no layer cooling.

Frederick

-

Thanks Fredrick, I do have some other filaments somewhere, and your model has shown me that the printer is capable of printing well, if the conditions are right. I as using ABS, since I thought that if I could get that to print well, everything else should be easy.

Thanks for your help. -

I think that before embarking on anymore tests, I will put the printer back in its thermal home. I only had it out to solve other issues, which are fixed now.

Once it is back, I'll level the bed properly and let you know how it goes. -

Oh, and as far as rigidity goes @antlestxp , I have modified the printer and added fairly heavy steel cross pieces on the Y axis and installed rectangular steel bracing pieces into the existing frame. You can see the front cross piece in the photo of the printer above. The standard Black Widow looks quite different.

If you think I need to go further, please let me know.

-

@dmbgo said in Problem with rear side of Test Cube:

I think that before embarking on anymore tests, I will put the printer back in its thermal home. I only had it out to solve other issues, which are fixed now.

Once it is back, I'll level the bed properly and let you know how it goes.I check this site on a regular basis so if you include @fcwilt I will get alerted to your posts.

I will not be at all surprised if ABS prints fine with the enclosure.

If you haven't researched PETG I think you should check it out.

This was posted on ALL3DP.COM:

PETG is stronger, more durable and it prints better. It's also available in transparent colors. ABS is only necessary if you absolutely need the 100°C temperature resistance or its ability to be glued and painted. Otherwise, it's difficult to justify the printing difficulties involved

Frederick